SEMICONDUCTOR LASER CUTTING MACHINE

men-luck laser cutting machine is mainly used for laser micro-machining of ceramic substrates, aluminum substrates, copper substrates, chips, COF, and copper foil antennas. The main materials that can be processed include aluminum, copper, tungsten, molybdenum, nickel, titanium, zinc, magnesium, magnets, silicon steel, powder metallurgy, ceramics, copper foil, aluminum foil, carbon fiber, glass fiber, pet, pi and other materials.

What is a semiconductor integrated circuit?

Application of laser cutting in semiconductor integrated circuits?

Semiconductor integrated circuits are widely used in daily electronic products, such as cars, televisions, computers, laptops, smartphones, etc. The upgrading of electronic equipment, coupled with the increasingly smaller size of equipment and the demand for refinement in the industry, have made semiconductor integrated circuits smaller and smaller. The accuracy and efficiency of traditional processes for processing semiconductors cannot meet the needs of the modern market. However, with the advent of laser With the wide application of cutting, more accurate and efficient laser micro-cutting technology is suitable for the fine micro-processing requirements of semiconductor integrated circuits.

Semiconductor integrated circuit laser micromachining applications

Our laser cutting machines are mainly used for laser micro-processing of ceramic substrates, aluminum substrates, copper substrates, chips, COF, films, copper foil antennas and other materials.

Semiconductor cutting applications

- FPC board laser cutting and forming

- PCB board laser cutting and forming

- Chip laser cutting and formings

- COF laser cutting and forming

- Aluminum substrate laser cutting and forming

- Copper substrate laser cutting and forming

- Silicon oxide, zirconia ceramic laser cutting

- Ceramic substrate laser cutting and forming

Materials Used for Semiconductor

- Aluminum, copper, silicon steel, tungsten, nickel, titanium, magnesium

- Copper foil, aluminum foil and other ultra-thin metal materials

- Carbon fiber, glass fiber, PET, PI and other ultra-thin composite materials

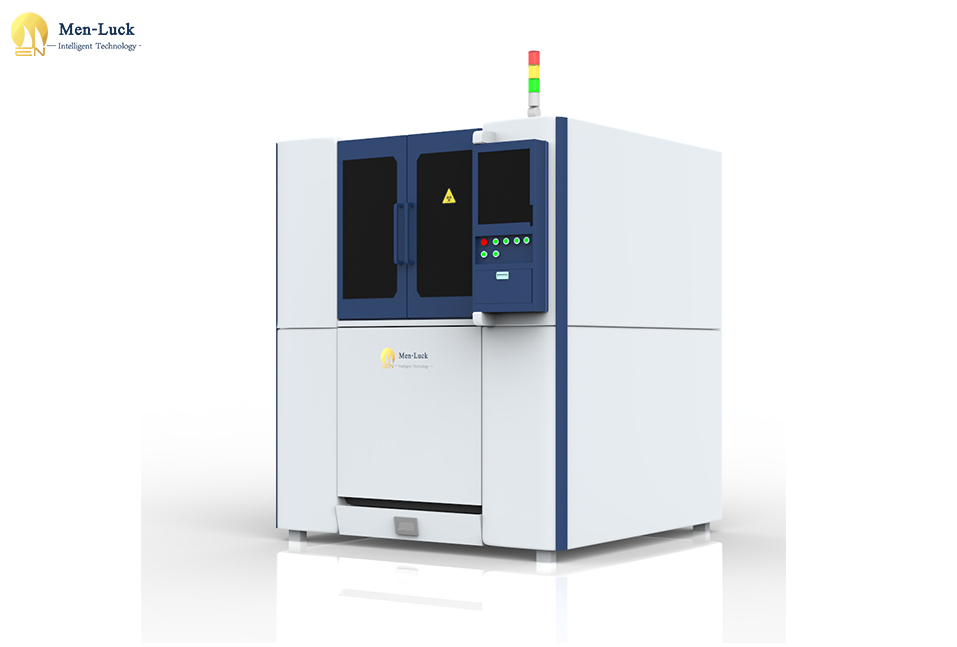

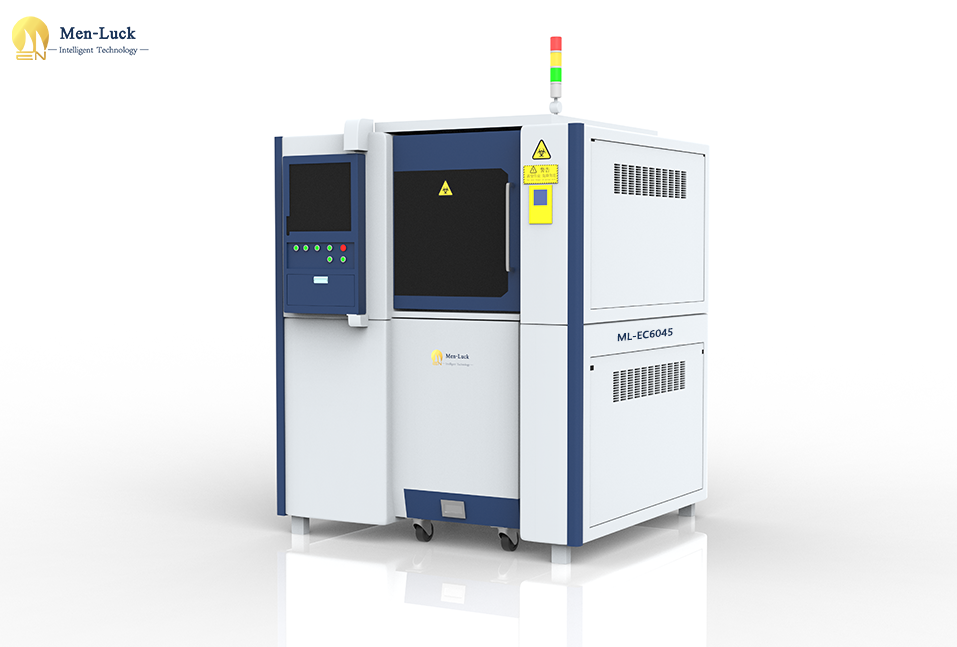

Our Semiconductor Laser Cutting Machine

- Copper substrate laser cutting machine

- Aluminum substrate laser cutting machine

- PCB substrate laser cutting machine

- PCB UV laser cutting machine

- Ceramic substrate laser cutting machine

- Circuit board laser cutting machinee

- Circuit board laser cutting depanel machine

- Sensor laser cutting machine

- Film laser cutting machine

- Fiber laser cutting depanel machine

- Hard brittle material laser cutting machine

- Shielding material laser cutting machine

- Precision laser etching machine

- Femtosecond laser cutting machine

LASER CUTTING MACHINE PRODUCTS

Our laser cutting machines are mainly used for laser micro-machining of aluminum substrates, copper substrates, PCB circuit boards, FPC circuit boards, silicon oxide ceramics, zirconia ceramics, chips, COF, and copper foil antennas.

Precision Laser Cutting Machine for Hard Brittle M…

Application Precision laser cutting machine for hard and brittle materials is mainly used for lase…

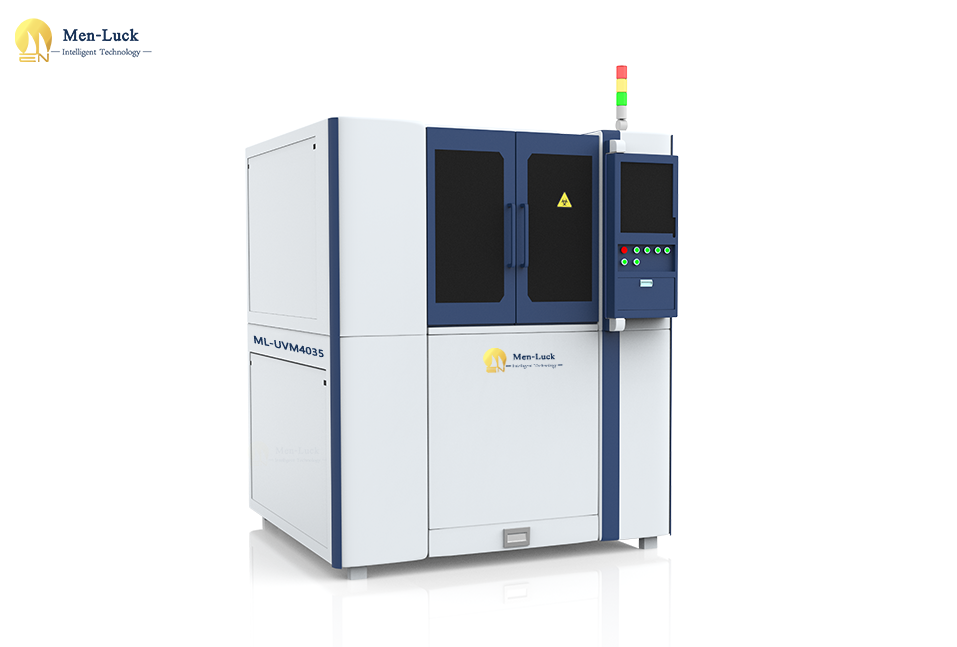

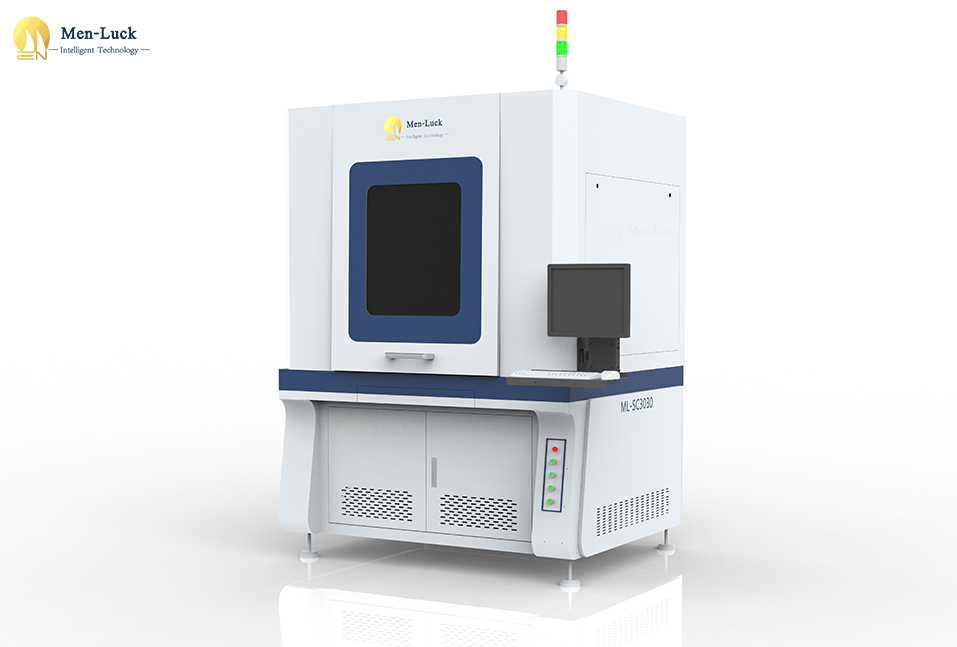

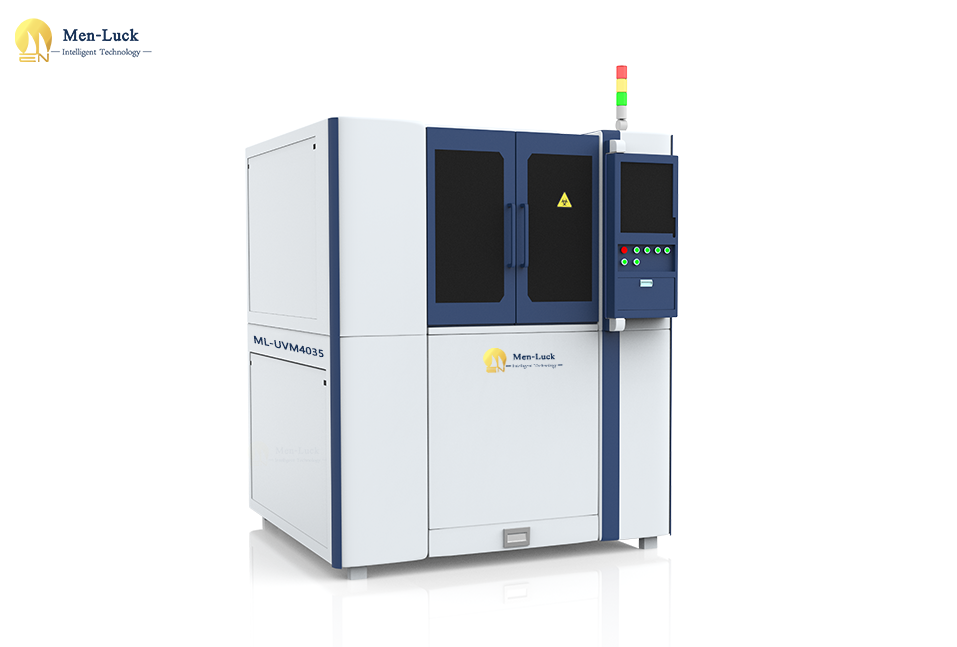

PCB UV Laser Cutting Machine ML-UVM4035

Application Ultraviolet laser cutting machine is mainly used for PCB laser board splitting and dri…

Precision Optical Fiber Laser Cutting Machine for …

Application Laser micro-machining of planar and curved surfaces of Al & Cu & W & Mo &a…

Laser Cutting Machine for Precision Alloy Instrume…

Application Laser micro-machining of planar and curved surfaces of Al & Cu & W & Mo &a…

CIRCUIT BOARD LASER CUTTING SAMPLE DISPALY

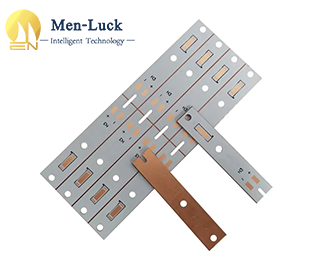

Aluminum substrate laser cutting forming

Laser cutting forming of copper substrate

Silicon steel sheet laser cutting forming

Copper sheet laser cutting forming

CIRCUIT BOARD LASER CUTTING VIDEO

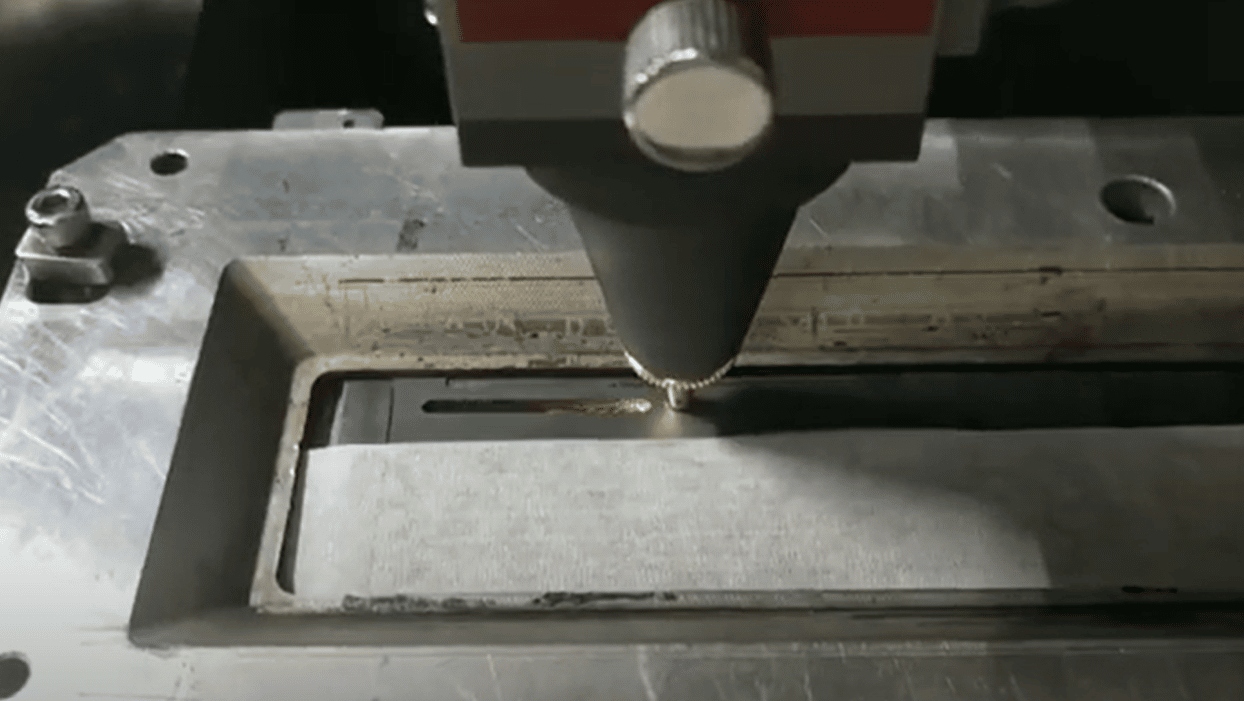

Men-Luck semiconductor laser cutting machine is mainly used for ceramic substrate, aluminum substrate, copper substrate, chip, COF, copper foil antenna, all kinds of stainless steel sheet, metal structural parts of laser micromachining. Below are some laser cutting application videos.

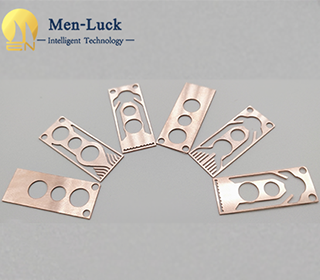

Femtosecond laser cutting machine is a type of cutting machine, but it has the best cutting technology among laser cutting equipment. It is a must-choice for cutting high-quality products in terms of cutting quality and cutting speed. Femtosecond laser cutting machines are used in the production of more precision instruments, semiconductor structural parts, and testing instruments, such as semiconductor test sockets, test probes, test blades, chip cutting, heart stents, vascular stents, hypotubes, etc. The following femtosecond laser cutting machine manufacturer men-luck introduces the laser cutting process of semiconductor test sockets in detail.

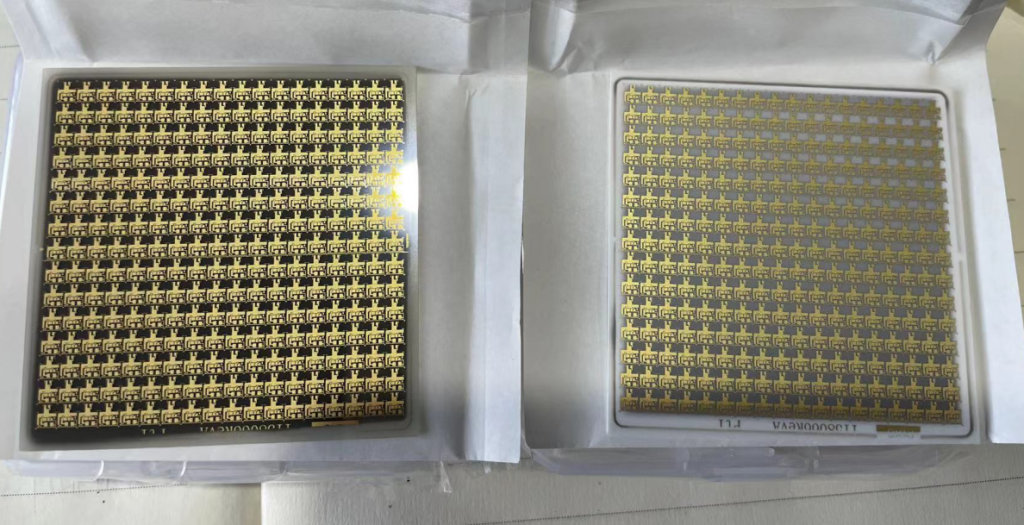

Electronic products have spread into every corner of our lives, and chips are important components of these electronic products. Mobile devices such as mobile phones, tablets, and automotive information systems have more complex system-on-chips, and these system-on-chips have multiple processing components such as CPU, GPU, AI engine, camera processor, memory, and 5G modem all combined into one chip This leads to space compression, cost and power consumption challenges. At the same time, it also puts forward higher requirements for test sockets for testing system-level chips. Semiconductor test sockets can also be called chip test sockets. Semiconductor test sockets can provide a stable and reliable interface through which the test equipment and the device under test can be linked to detect chip quality and performance standards.

It is necessary to add more functions on the smallest possible chip, which results in very few integrated circuits, even less than 500 microns. It is also necessary to integrate key system components on one chip. The improvement of chip performance will cause Pin-to-pin noise, or “crosstalk” as it’s called in testing, can easily lead to false fault tests. Chip test sockets can make full use of the coaxial technology of integrated circuits to achieve 350µm spacing and provide ideal pin-to-pin isolation, reducing the impact of crosstalk during testing. The small diameter signal probe of the semiconductor chip test socket greatly improves the accuracy of chip performance testing. The high-precision production of semiconductor chip test sockets requires femtosecond laser cutting machines.

![]()

The men-luck femtosecond laser cutting machine adopts the most advanced ultra-short pulse laser technology and can be used for laser micro-machining of various metal and non-metal materials. The cutting accuracy is high and can reach 5um; the cutting slit width is small and can be less than 20um; the heat dissipation speed is fast, which can avoid thermal effects, has no impact on the performance and quality of the production materials, and will not cause problems such as yellowing or blackening; the cutting surface is smooth and can be used in one go It can permanently cut through materials or single-sided pipe walls, and has fine processing capabilities such as dry and wet cutting, drilling, and engraving; supports the processing capabilities of centripetal, vertical, and composite opening features of equal-diameter pipes, variable-diameter pipes, planes, and complex curved surface instruments. ; Become a necessary equipment for the cutting and drilling process of semiconductor test sockets.

The men-luck femtosecond laser cutting machine can meet the processing needs of all industries that require high-precision processing without affecting quality and production efficiency. Such as various miniaturized components in the electronic 3C and semiconductor integrated circuit industries, various interventional medical devices such as coronary stents, cardiac stents, thrombectomy stents, degradable stents, lithotomy baskets, intravenous filter microstructures, etc. in the medical industry. Surgical instruments, these delicate small parts or instruments require processing by femtosecond laser cutting machines to meet high-precision and high-quality product requirements. men-luck femtosecond laser cutting machine has rich application and production experience in medical equipment, electronic 3C, semiconductor integrated circuit and other industries. If you have needs, you can call us for consultation or mail materials for sample cutting tests to verify men-luck femtosecond laser cutting machines. The power of laser cutting machines.

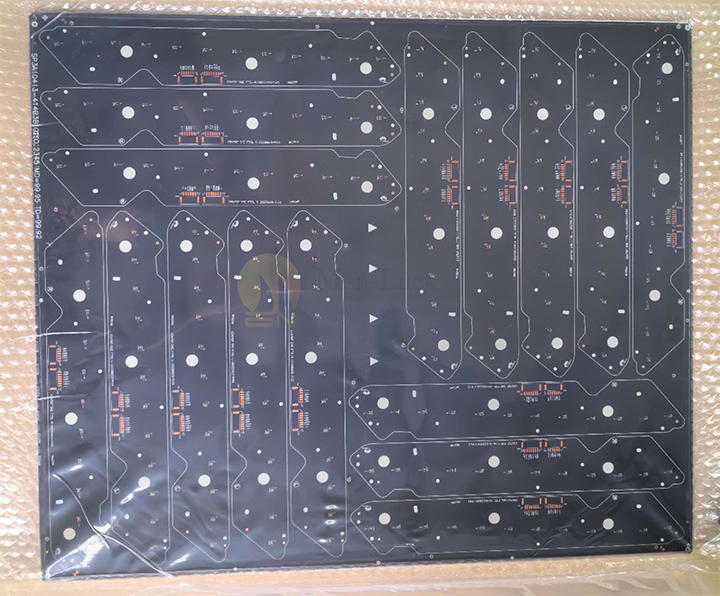

Flexible copper-clad laminate is a copper-clad laminate formed by bonding one or both sides of a flexible insulating material such as polyester film with copper foil through process treatment. It is also called a flexible copper-clad laminate. It is widely used in various electronic products such as navigation equipment, aerospace equipment, aircraft instruments, mobile phones, digital cameras, automobiles, satellite positioning devices, notebook computers, and LCD TVs. Due to the rapid development of electronic technology, the output of flexible copper-clad laminates has increased significantly, and the production scale needs to be expanded. A laser cutting machine is required in the laser cutting process of the copper-clad circuit board production process. The following professional laser cutting machine manufacturer will provide you with a detailed analysis of the laser cutting process of copper-clad circuit boards.

At present, the cutting process of copper-clad circuit boards mainly uses laser cutting, which is also the cutting process with the best cutting effect. After years of technical accumulation, men-luck has developed a laser cutting machine specifically for circuit boards. This machine uses non-contact laser cutting with high precision, smooth cutting surface, no stress, small heat-affected area, and no yellowing or blackening. For quality problems, system control is adopted to achieve high production efficiency. Automatic loading and unloading systems and visual positioning systems are also optionally available to monitor the entire process, making it the most ideal equipment choice for circuit board cutting.

This circuit board laser cutting machine is widely used in the fine board cutting process of various circuit boards such as hard boards, soft boards, copper-clad boards, aluminum-clad boards, etc. The equipment has passed 3C certification, with stable performance and reliable quality. In addition, our company provides circuit board proofing of various materials all year round. If you have needs, please feel free to mail samples at any time.

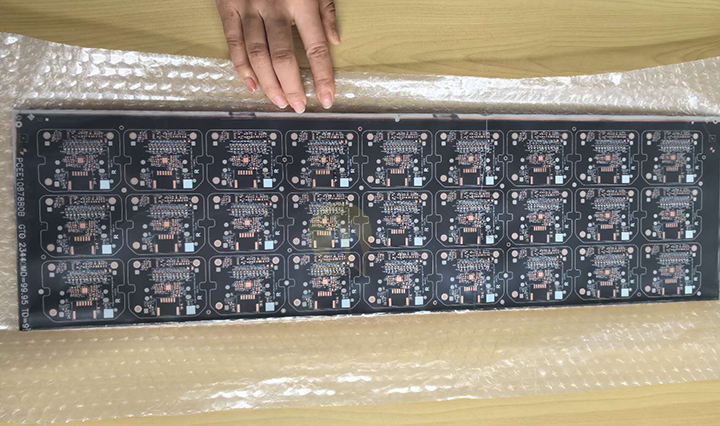

Let’s take a look at the PCB printed circuit board samples just mailed by the customer yesterday. They are copper-clad circuit boards and aluminum-clad circuit boards. This circuit board is mainly used for car headlights and is waiting for proofing!

PCB aluminum-coated circuit board sample

PCB copper-coated circuit board sample material

Precision laser cutting machine manufacturer men-luck is a professional manufacturer of laser micro-machining equipment, equipment variety, complete models, can meet a variety of materials of plane, surface, tube products laser cutting needs, the following laser cutting process for flexible lamp belt detailed introduction.

LED lights can be seen everywhere in daily life, the flexible lamp belt for LED lights is a breakthrough product in LED light technology, because of its soft and durable, low cost, small structure, strong light, but also make up for the lack of glass neon tubes, more energy saving and environmental protection, has become the mainstream development direction of the LED light market. In the production process of the lamp belt need to be cut, because of the high cutting process requirements, need to use a special laser cutting machine to cut out high-quality flexible lamp belt.

Cutting in the long hundreds of meters, 1mm wide flexible light belt, the traditional cutting method is difficult to achieve accurate size, high quality cutting effect, but the men-luck flexible light belt laser cutting machine can do it, the cutting machine is a high-precision fiber laser cutting machine dedicated to metal materials, the light source is stable, the use of non-contact cutting, high precision. The heat affected area is small, the cutting surface is smooth and flat, no black and yellow problems, is an efficient and energy-saving precision laser cutting machine, very suitable for the cutting of LED flexible light belt.

LED flexible lamp laser cutting machine is also widely used in medical equipment, electronic 3C, semiconductor integrated circuit field. men-luck can optimize the configuration of the equipment according to the different applications, such as fiber laser, femtosecond laser, cutting head, automatic vision compensation system, automatic loading and unloading system, etc., can be configured according to the actual needs of customers.

As energy-saving and environmentally friendly travel tools, new energy vehicles are promoted by the state. Supported by purchase policies, more and more people buy electric vehicles. The biggest difference between new energy vehicles and fuel vehicles is that the core power is changed from fuel to lithium battery. Lithium batteries are mainly divided into three parts: pole piece manufacturing, battery cell manufacturing and battery assembly. Every step affects the quality and performance of lithium batteries, so it is important to strictly control the production quality of each step. The cutting process of lithium battery pole pieces requires the use of high-precision laser cutting machines.

The men-luck lithium battery laser cutting machine has high cutting precision, smooth cutting surface, fast cutting speed, and small heat-affected area, so it has no thermal impact on the chip surface, will not turn yellow or black, and will not affect the quality and performance of the chip. It well avoids some problems that affect chip quality such as chip wear, slag, and dust that occur in traditional cutting methods. These quality problems may cause battery overheating, short circuit, or even explosion. This cutting machine is a new generation of high-energy-efficiency laser cutting machine developed by men-luck based on many years of production experience. It has high cutting efficiency and low operating costs. It is a precision laser cutting machine with high cost performance.

In addition to cutting chips, lithium battery laser cutting machines can also be used for cutting metal foil, isolation films, cover films and other electronic 3C structural parts and integrated circuit-related accessories. In addition, men-luck can also customize equipment, laser heads, and lasers according to customer application cutting needs. Generally, the delivery cycle of customized laser cutting equipment is 15-45 days later than that of ordinary equipment, but we guarantee that the quality of the equipment must be the best. Okay, after completing production, we will conduct machine testing and trial operation of the equipment, and then cut samples to ensure that all performance indicators and parameters of the equipment are within the normal range, and it can be used normally after it is delivered to the customer.

If you have any purchase needs for laser cutting machines, laser welding machines, laser engraving machines and other equipment, please feel free to call or email us for consultation and negotiation. All our laser micro-machining equipment are complete in variety and model, and can meet the laser processing needs of various applications.

the application of electronic products more and more extensive, but also more and more miniaturized, not only multi-functional, but also high performance. This has promoted the rapid development of PCB to high-density and high-precision, and ceramic circuit board is one of them. Ceramic circuit board is widely used in 3C electronics industry because of its mechanical stress, good thermal cycling and electrical insulation properties.

The main raw materials of thin film ceramic substrate include zirconia, aluminum nitride, alumina (AL2O3), silicon oxide and so on. Alumina has the advantages of wear resistance, corrosion resistance, high temperature stability, high hardness and excellent mechanical properties, and is the most used ceramic substrate material.

Alumina film substrate sample

Because of its high hardness and high brittleness, the ceramic substrate is relatively easy to break, which increases the difficulty of cutting. The laser cutting is a kind of thermal cutting, which can avoid the problem of fragile cutting well, and the high energy laser beam can irradiate the surface of the ceramic substrate and melt instantly to achieve the purpose of cutting. men-luck ceramic laser cutting machine can process any graphics, automatic CCD focusing, positioning, automatic box to box loading and unloading, is the film circuit, microwave communication and other electronic components of the ceramic circuit board processing the most ideal choice.

Ceramic laser cutting machine is dedicated to laser cutting, drilling, marking and other micro-processing of ceramic materials. Years of laser cutting machine R & D and production experience, mature equipment process, advanced technology, according to customer processing needs to proofing, and provide proofing quality testing, but also according to demand for ceramic laser cutting machine equipment customized models, in the use of any problems, we provide 24 hours of after-sales technical support. Welcome new and old customers to inquire and negotiate business.

7x24 Hours Service

If you have any problems that can't be solved, you can leave your contact information, so that we can communicate with you in time.

-

-

Ask your question

-

Company Office

Floor 3, Block 6, Dongaoxingu No.1 Industrial Park, No.1 Kele Road, Xinbei District, Changzhou City, Jiangsu Province.

WhatsApp:

WhatsApp: Wechat

Wechat

Femtosecond laser cutting machine semiconductor test socket production process 2023-11-28

Femtosecond laser cutting machine is a type of cutting machine, but it has the best cutting technology among laser cutting equipment. It is a must-choice for cutting high-quality products in terms of…