STENT CUTTING

MEN-luck Laser cutting machine are suitable for heart valve, mitral valve, peripheral and lower extremity bare metal stents and drug-coated stents, bare metal stents, coronary stents, venous filters and other drug-coated stents

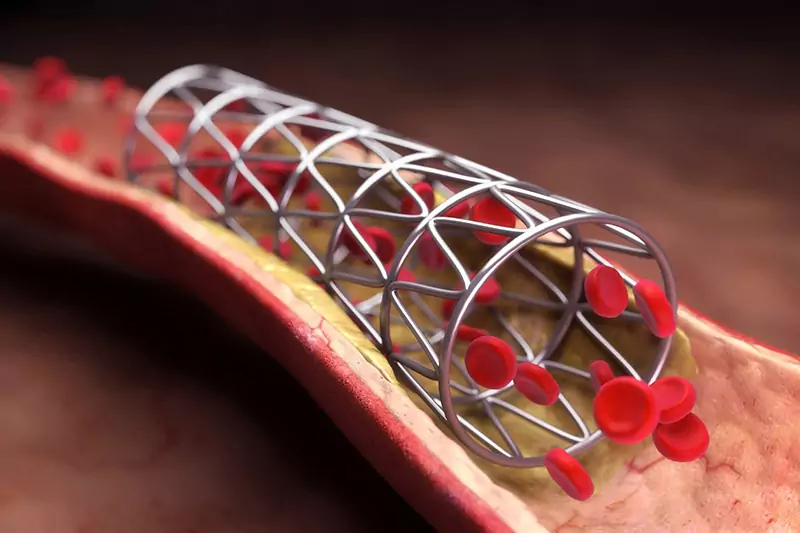

What is a stent?

Application Of Laser cutting In Medical Stent

This process is particularly effective in the production of medical devices, such as catheters, heart valves and medical stents, and can be used for glass cutting and marking applications, as well as 3D structure manufacturing of dental implant ceramic materials. However, perhaps the most potential application lies in a new type of bioabsorbable materials, that is, polymer materials that can be safely retained in the body and subsequently absorbed within a controlled length of time. These materials are currently under development and will be used to replace traditional polymers or metal parts.

Medical Stent Cutting applications

Our Laser cutting machine and laser cut stent are suitable for heart valve, mitral valve, peripheral and lower extremity bare metal stents and drug-coated stents, bare metal stents, coronary stents, venous filters and other drug-coated stents

Stent Laser cutting applications

- Heart valve frames

- Neurovascular retrieval stents

- Carotid stents

- Peripheral stents

- Biliary stents

- Delivery system components

Materials Used for stent

- 316 Stainless Steel (SS 316): Chromium, nickel and molybdenum alloy

- Nitinol (NiFi): Nickel and titanium alloy

- Magnesium (Mg) Alloys

- Platinum Chromium Alloy

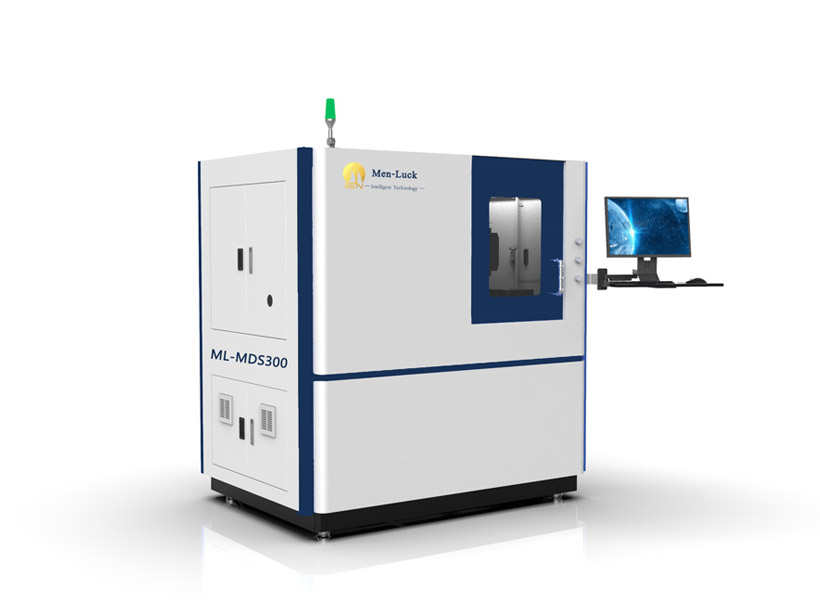

Our Laser Cutting Machine

- Stent Laser Cutting Machine

- Brain plate laser cutting machine

- Hypotube Laser Cutting Machine

- Spiral Tube Laser Cutting Machine

- Nose drill laser cutting machine

- Endoscope Bending Section cutting machine

- Infrared Laser Cutting Machine

- Vein Filter Laser Cutting Machine

- Connecting sheet laser cutting machine

- Ultrasonic Knife Laser Cutting Machine

MEDICAL DEVICE PRODUCTS

The products are suitable for heart valve, mitral valve, peripheral and lower extremity bare metal stents and drug-coated stents, bare metal stents, coronary stents, venous filters and other drug-coated stents, rigid endoscopes, ultrasonic scalpels, endoscopy Surgical and orthopedic instruments such as endoscopes, staplers, staplers, soft drills, planers, puncture needles, nasal drills, medical endoscopes such as urological endoscopes, common bile duct endoscopes, gastrointestinal endoscopes, anorectal endoscopes, etc. Laser micromachining of industrial endoscopes and electronic endoscopes.

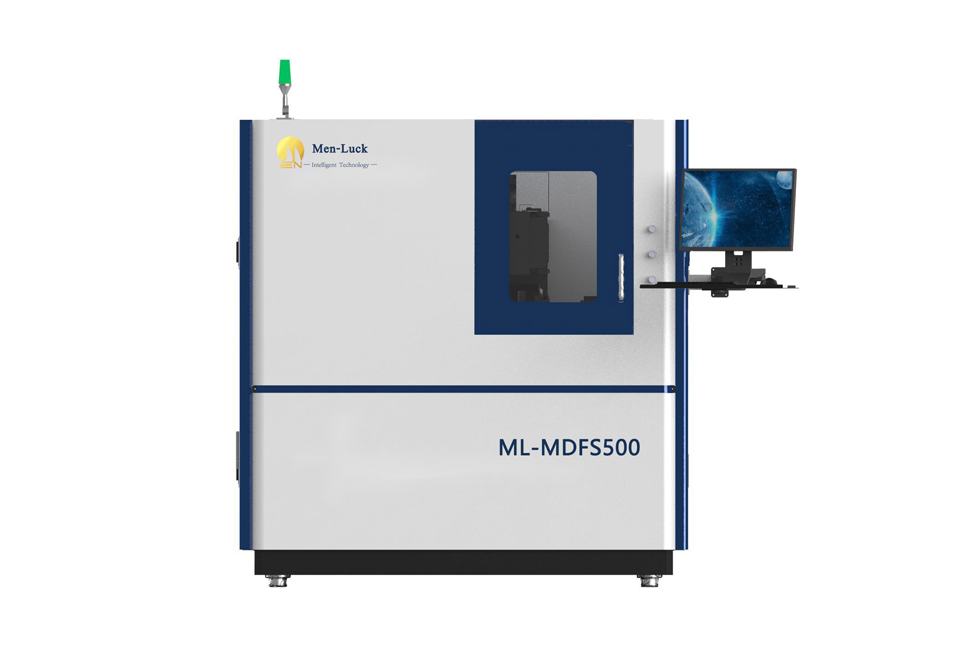

Laser Cutting Machine for Medical Big Stent ML-MDS…

Application Medical large stent laser cutting machine mainly uses heart valve, mitral valve, perip…

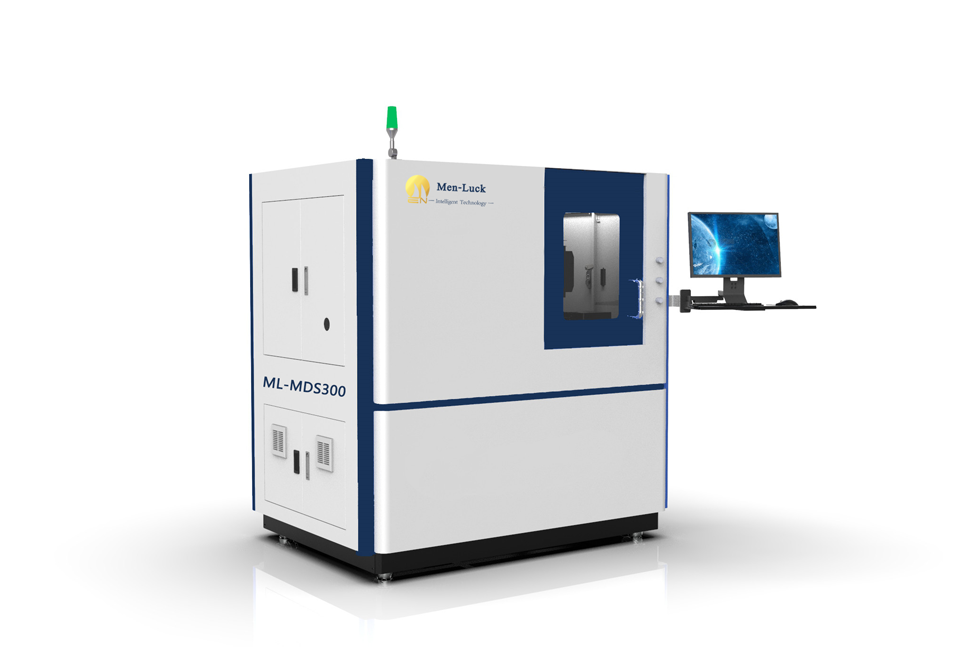

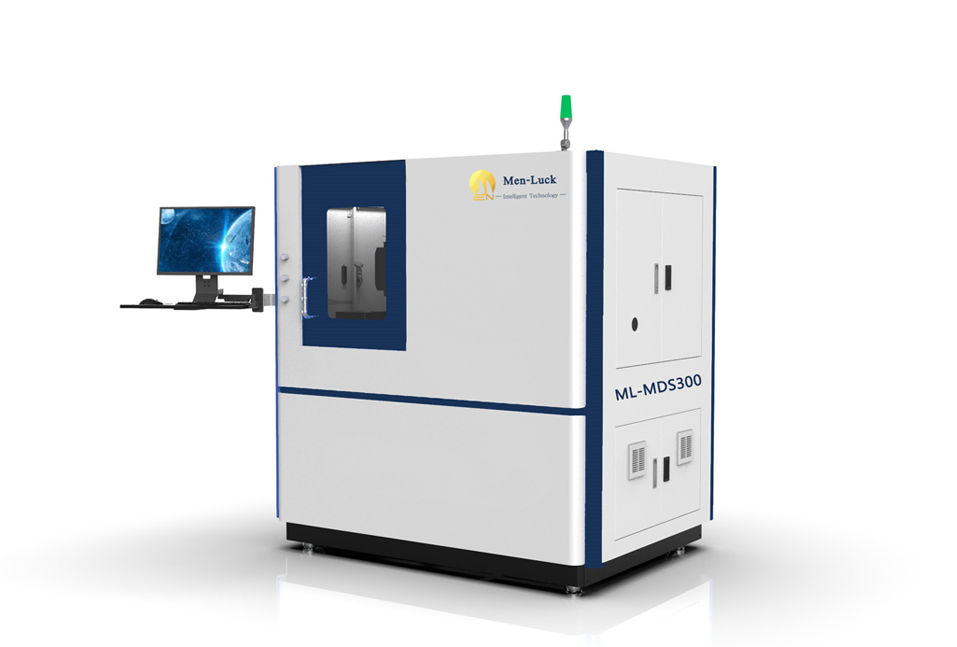

Laser Cutting Machine for Medical Stent ML-MDS300(…

Application Medical stent laser cutting machine is mainly used for laser micromachining of small-d…

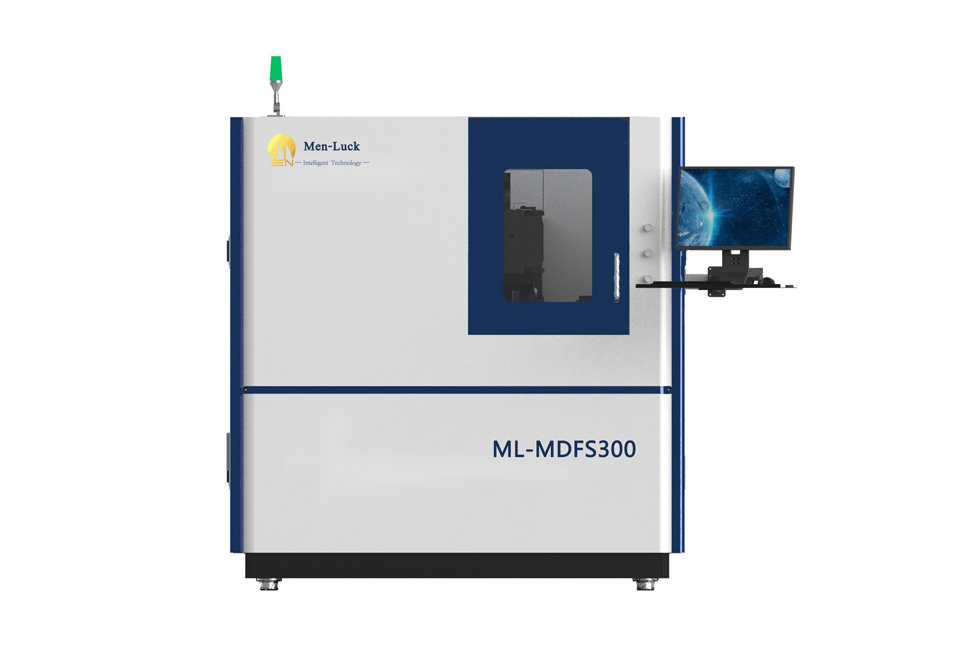

Ultrafast femtosecond stent laser cutting machine …

Application Four-axis super fast femtosecond stent laser cutting machine is mainly used for laser …

UltraFast Femtosecond Laser Cutting Machine For st…

Application Super fast femtosecond stent laser cutting machine is mainly used for intracranial thr…

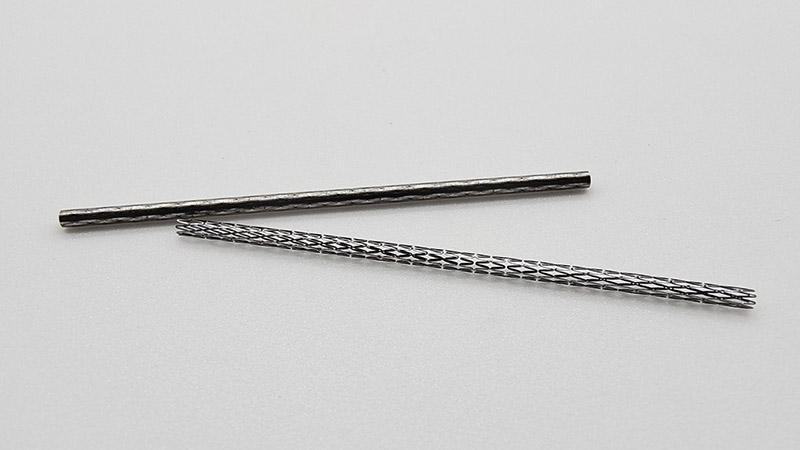

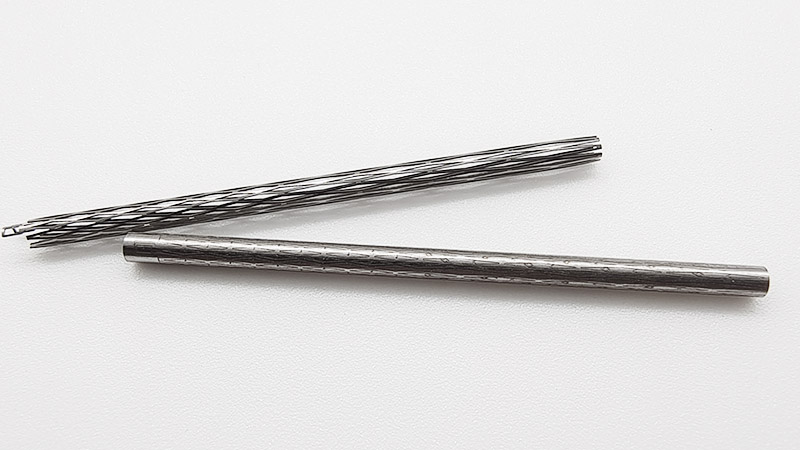

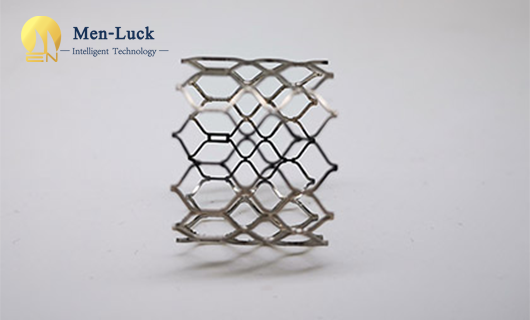

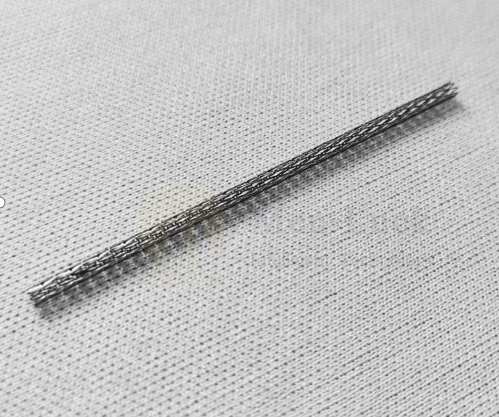

Stent Cutter Sample Display

OD1.6CNR20

Material: Co-Cr L605

OD: 1.6mm

WT: 0.09mm

L:20mm

OD1.6CNR48

Material: Co-Cr L605

OD: 1.6mm

WT: 0.09mm

L:48mm

OD1.8CCMV32

Material: Co-Cr L605

OD: 1.8mm

WT: 0.1mm

L: 32mm

OD1.8CCMV48

Material: Co-Cr L605

OD: 1.8mm

WT: 0.1mm

L: 48mm

OD1.8SSMV16

Material: SS 316L

OD: 1.8mm

WT: 0.11mm

L: 16mm

OD1.8SSMV40

Material: SS 316L

OD: 1.8mm

WT: 0.11mm

L: 40mm

OD2.6DIA40mm

Material: Ni-Ti

OD: 2.6mm

WT: 0.2mm

L: 40mm

OD2.6DIA50mm

Material: Ni-Ti

OD: 2.6mm

WT: 0.2mm

L: 50mm

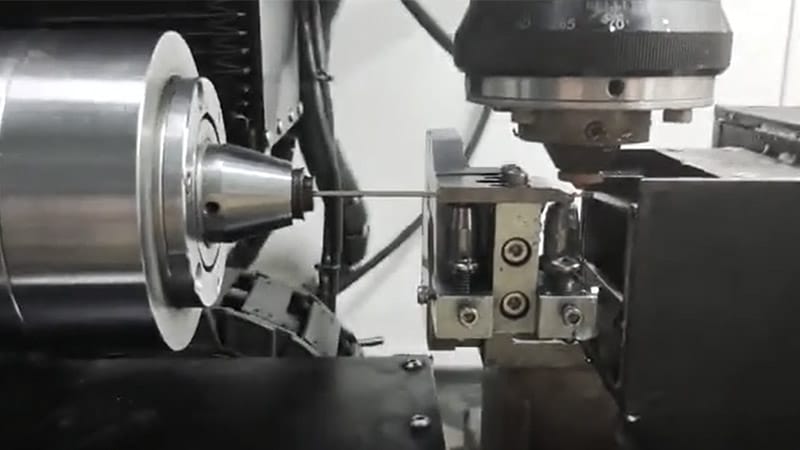

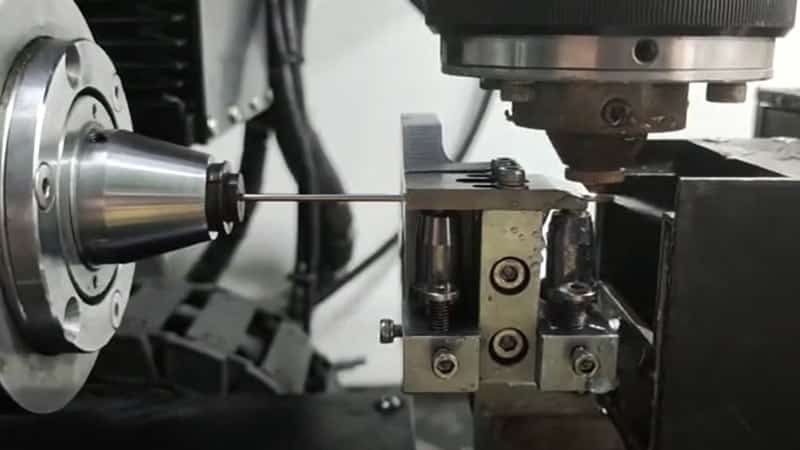

Stent Cutting Machine Video

Our Laser cutting machine are suitable for heart valve, mitral valve, peripheral and lower extremity bare metal stents and drug-coated stents, bare metal stents, coronary stents, venous filters and other drug-coated stents

Laser cut stents are typically characterized by their high precision, accuracy, and repeatability. They are also designed to be lightweight and durable, and they are often made from materials such as stainless steel, titanium, and nitinol. Additionally, laser cut stents are often designed to be resistant to corrosion and wear, and they are often used in medical applications due to their biocompatibility.

Laser cutting of stents is a process that uses a laser beam to cut the stent material into the desired shape. The laser beam is focused on the stent material and the heat generated by the laser beam melts or vaporizes the material, allowing it to be cut into the desired shape. The laser cutting process is precise and can be used to create intricate shapes and patterns.

The lasers cut stent is guided by a computer–controlled system that allows for precise cutting of the stent material. The laser beam is also used to weld the stent material together, creating a strong and secure bond.

With the soaring incidence of cardiovascular and cerebrovascular diseases, stent implantation has become one of the main methods of surgical treatment. Compared with traditional cutting equipment, medical laser cutting machine not only has good cutting quality, high cutting precision, but also has high efficiency and low cost, and has become an essential equipment for medical stent production.

A stent is a netted tubular material used to implant a tube to support the diseased site and restore its transport function, or an auxiliary coil to isolate a hemangioma during isolation surgery. From the material scaffold can be generally divided into three kinds. The first is a traditional stent, a bare metal stent, which is placed in the affected area and then expanded or compressed by a balloon to expand itself to support the blood vessel. In order to reduce the re-narrowing of blood vessels, the second stent is coated with drugs to inhibit the proliferation of blood vessel walls, that is, drug-coated stents. Since the stent will remain in the body, if a new stent needs to be implanted again, a different location will need to be selected. Therefore, the third kind of biodegradable scaffold came into being. The scaffold made of biodegradable materials in the human body will dissolve and be absorbed, and gradually decompose the implanted scaffold structure. At this time, the blood vessels have been repaired and no additional assistance is needed. Biodegradable stents have become the most ideal choice for medical surgery.

So how does the super fast femtosecond laser cutting machine beat other processing methods?

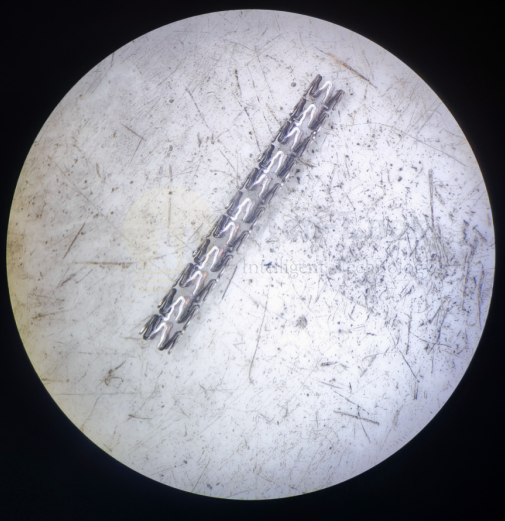

Because stents are complex and delicate medical products, the ideal stent needs to have the right smoothness to coat drugs and allow blood vessel cells to attach. It also has good visualization, so that medical personnel can locate and track the stent. Therefore, the cutting surface of the stent can not leave burrs or melting slag to avoid damaging the blood vessels. Therefore, the manufacturing method of the bracket will affect its fineness and surface smoothness, so qualified brackets require a high level of manufacturing technology. The advantages of ultra-fast femtosecond laser cutting machine non-contact cutting and high precision can perfectly meet the requirements of support cutting.

The peak power brought by the ultra-short pulse width of the ultra-fast femtosecond laser cutting machine will produce a multi-photon absorption effect, which will directly evaporate the material, skipping the melting process. Therefore, the ultra-fast femtosecond laser can be used for material processing with relatively low energy, no residue, and the heat affected zone is small, to achieve high precision and high cleanliness processing, and can omit post-processing and reduce costs. The super fast femtosecond laser requires little power, and when the laser cuts through the tube wall and then diverts to the opposite inner wall, its luminous flux is not enough to damage the inner wall, so it will not reduce the performance of the support.

Men-luck is mainly engaged in ultra-fast femtosecond laser cutting machine, medical stent laser cutting machine, snake bone laser cutting machine, needle laser cutting machine, medical plane laser cutting machine and other laser micro-processing equipment, which is widely used in the medical device industry to help the development of medical industry. In addition, Men-luck can also provide all kinds of medical equipment proofing services, welcome to call to make an appointment!

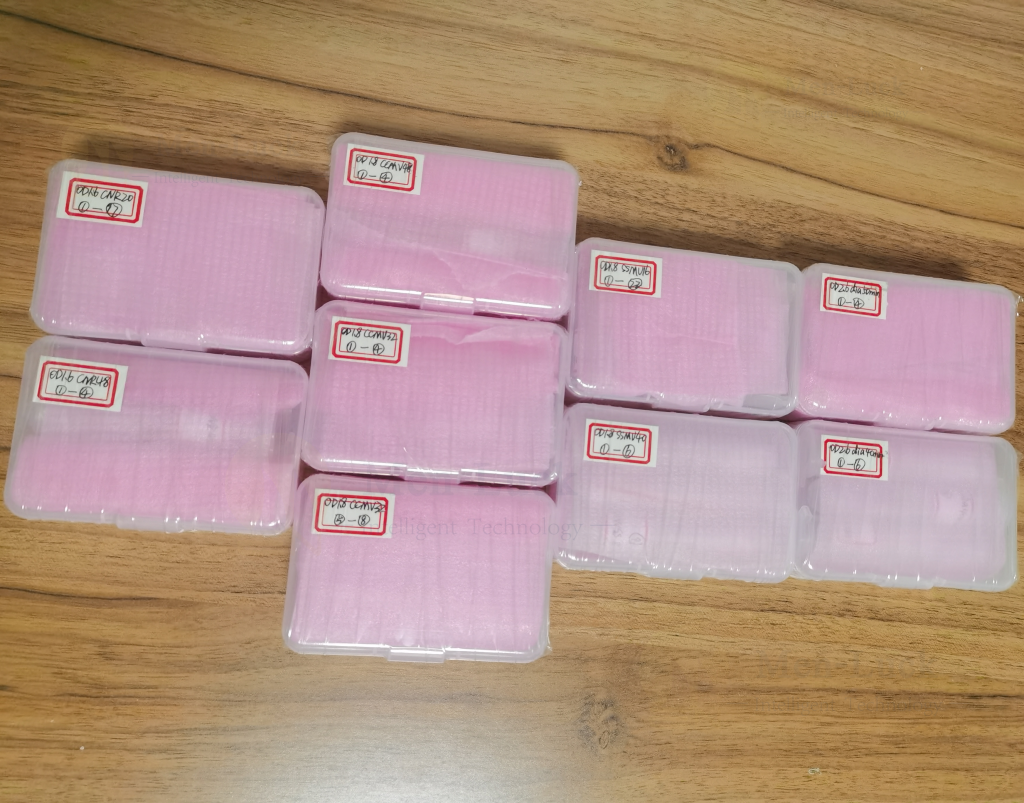

After 2 days of drawing, trial cutting, debugging, and testing by the company’s technical staff, 8 types of stents raw materials were successfully completed in accordance with the technical indicators required by the customer!

One of the newly processed bracket pictures

Enlarged picture of stent

As a well-known local manufacturer of cardiovascular medical devices, the Indian client plans to purchase a new generation of stents processing equipment with higher technical content in order to continuously improve the company’s market competitiveness and satisfy the needs of the medical industry for various types of tubular stents.

After one week communication about the cutting size and material of coronary stents and confirming our precision laser cutting equipment can meet the cutting needs of various materials and styles of stents, we sent sample drawings and processing requirements. After the review by our technical engineers, our precision cutting equipment could fully meet the processing needs, and the customer finally sent three kinds of stainless steel, nickel-titanium, and cobalt-chromium alloy stent pipes with different diameters.

Our company uses a precision laser cutting machine to process three coronary stent raw materials of different materials and different diameters into eight coronary stent samples, sales staff followed the whole proofing process, and showed customers the proofing process through video.Samples were provided for the supplied materials. A detailed and standardized quality inspection report was provided for each sample. After all the customer’s raw materials were proofed, we packaged and mailed to the customer at the fastest speed.

All coronary stent samples processed by BSLC300 precision laser cutting machine are sorted and boxed

Coronary stent samples are added with a protective layer and packaged for shipment

As a professional manufacturer of stents, our customer had a complete set of factory testing equipment. After receiving the samples, the customer carried out strict “factory quality inspection” on all proofing products. Through the proofing service, the customer really saw the gold processing capability of the MEN-LUCK precision laser cutting machine as well as our service capability and service attitude!

MEN-LUCK, as a well-known manufacturer of stent laser cutting equipment in China, has excellent processing equipment, mature and advanced technology and perfect service. We can provide customers with medical equipment such as stents, endoscopic snake bones, hypotubes, precision 3C structures, components, semiconductor integrated circuits and other laser micromachining system solutions. Proofing is the most powerful proof. For new customers in India, after successful proofing, can they sign a cooperation smoothly? Please continue to view the next share!

7x24 Hours Service

If you have any problems that can't be solved, you can leave your contact information, so that we can communicate with you in time.

-

-

Ask your question

-

Company Office

Floor 3, Block 6, Dongaoxingu No.1 Industrial Park, No.1 Kele Road, Xinbei District, Changzhou City, Jiangsu Province.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of laser cutting in medical stent 2022-07-06

The stent belongs to the third category of medical devices, that is, the highest level of medical devices. It is a slender metal grid, very small, with a diameter of 2 ~ 4 mm, a few centimeters long,…