Ultrafast femtosecond laser technology helps cardiovascular stent manufacturing

(Click 437 )With the soaring incidence of cardiovascular and cerebrovascular diseases, stent implantation has become one of the main methods of surgical treatment. Compared with traditional cutting equipment, medical laser cutting machine not only has good cutting quality, high cutting precision, but also has high efficiency and low cost, and has become an essential equipment for medical stent production.

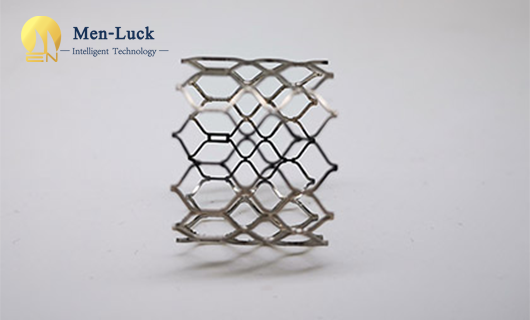

A stent is a netted tubular material used to implant a tube to support the diseased site and restore its transport function, or an auxiliary coil to isolate a hemangioma during isolation surgery. From the material scaffold can be generally divided into three kinds. The first is a traditional stent, a bare metal stent, which is placed in the affected area and then expanded or compressed by a balloon to expand itself to support the blood vessel. In order to reduce the re-narrowing of blood vessels, the second stent is coated with drugs to inhibit the proliferation of blood vessel walls, that is, drug-coated stents. Since the stent will remain in the body, if a new stent needs to be implanted again, a different location will need to be selected. Therefore, the third kind of biodegradable scaffold came into being. The scaffold made of biodegradable materials in the human body will dissolve and be absorbed, and gradually decompose the implanted scaffold structure. At this time, the blood vessels have been repaired and no additional assistance is needed. Biodegradable stents have become the most ideal choice for medical surgery.

So how does the super fast femtosecond laser cutting machine beat other processing methods?

Because stents are complex and delicate medical products, the ideal stent needs to have the right smoothness to coat drugs and allow blood vessel cells to attach. It also has good visualization, so that medical personnel can locate and track the stent. Therefore, the cutting surface of the stent can not leave burrs or melting slag to avoid damaging the blood vessels. Therefore, the manufacturing method of the bracket will affect its fineness and surface smoothness, so qualified brackets require a high level of manufacturing technology. The advantages of ultra-fast femtosecond laser cutting machine non-contact cutting and high precision can perfectly meet the requirements of support cutting.

The peak power brought by the ultra-short pulse width of the ultra-fast femtosecond laser cutting machine will produce a multi-photon absorption effect, which will directly evaporate the material, skipping the melting process. Therefore, the ultra-fast femtosecond laser can be used for material processing with relatively low energy, no residue, and the heat affected zone is small, to achieve high precision and high cleanliness processing, and can omit post-processing and reduce costs. The super fast femtosecond laser requires little power, and when the laser cuts through the tube wall and then diverts to the opposite inner wall, its luminous flux is not enough to damage the inner wall, so it will not reduce the performance of the support.

Men-luck is mainly engaged in ultra-fast femtosecond laser cutting machine, medical stent laser cutting machine, snake bone laser cutting machine, needle laser cutting machine, medical plane laser cutting machine and other laser micro-processing equipment, which is widely used in the medical device industry to help the development of medical industry. In addition, Men-luck can also provide all kinds of medical equipment proofing services, welcome to call to make an appointment!

WhatsApp:

WhatsApp: Wechat

Wechat

Advantages of laser cutting nickel-titanium electrode 2024-05-06

In recent years, with the continuous development of medical technology, medical laser cutting machines play an important role in the manufacture of nickel-titanium electrode sheets. Next, we will introduce the application and advantages of our Men-luck laser cutting machine in t…

Laser cutting process of eye lens 2024-04-11

With the increasing demand for vision correction in modern society, glasses, as a common optical instrument for vision correction, play an indispensable role in People's Daily life. Lens processing is a delicate process that requires cutting and punching to complete the manufact…

Application of laser cutting machine in mobile phone camera module manufacturing 2024-04-04

With the continuous progress of science and technology and the improvement of people's requirements for quality of life, the fields of smart wear, smart home, automotive electronics and mobile phone consumer electronics have been vigorously developed. In these fields, the camera…

Metal laser tube cutting machine for furniture industry to reduce production costs 2024-04-01

The metal laser tube cutting machine can cut and punch various types of metal tube materials such as metal round pipes and square pipes according to the needs of use, and the precision is high and the quality is good. In the current era of diversified and light luxury furniture,…