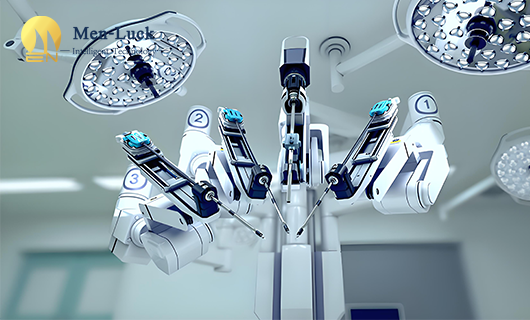

Application of medical laser cutting machine in the field of medical equipment

(Click 421 )Due to the special use environment of medical devices, there are special requirements for their precision, safety, cleanliness, etc., so in the production and manufacture of medical devices, manufacturers must be strictly required from the source. In the process of metal medical device processing, the traditional mechanical cutting processing mode has certain defects in precision, safety and controllability, and the medical laser cutting machine is not only high precision, fast speed, but also can maintain high consistency, so the traditional processing method is replaced by laser cutting is the inevitable trend of the development of the industry.

The medical laser cutting machine uses a high-density laser beam to scan the surface of the material, so that the material is quickly heated to vaporization and evaporation to form holes. As the laser beam moves on the surface of the material, the auxiliary gas blows away the impurities generated from the slit, so that the hole continuously forms a narrow slit to complete the cutting of the material.

This laser cutting process ensures that the instrument is not secondary pollution in the processing process, and makes the section smooth without burrs, which can meet the requirements of a molding, reduce the post-processing work after the material is formed and save time. From the workpiece itself, medical devices are very different from other simple mechanical parts, especially in terms of accuracy requirements. The medical laser cutting machine can be accurately processed according to the required accuracy, and the maximum accuracy can reach 7 microns, which is impossible to achieve by other processes. And the processing process of the medical laser cutting machine is non-contact, the laser cutting head will not be in contact with the surface of the processed material, and the situation of scratching the workpiece will not occur.

As a professional manufacturer of laser micro-processing equipment, men-luck’s main equipment types include medical laser tube cutting machine and medical laser plate cutting machine, such as stent laser cutting machine, snake bone laser cutting machine, sea wave tube laser cutting machine, surgical instrument laser cutting machine and other equipment, as well as batch processing services. Our company supports sending material proofing, can provide system solutions according to customer needs, welcome customers to contact us.

WhatsApp:

WhatsApp: Wechat

Wechat

Femtosecond laser cutting machine reshapes the limit of ultra-precision manufacturing 2025-07-08

In the field of cutting-edge manufacturing that pursues micron or even nanometer precision, traditional processing methods have gradually reached physical limits. The emergence of femtosecond laser cutting machines, with its revolutionary "cold processing" characteristics brough…

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…