Product introduction of laser cutting machine manufacturers

(Click 1,172 )

There are many factors that affect the laser cutting machine: laser power and brand, laser cutting head, machine stability, application field, processing technology, processing control accuracy, processing format, processing materials, whether equipped with an automatic system, etc.

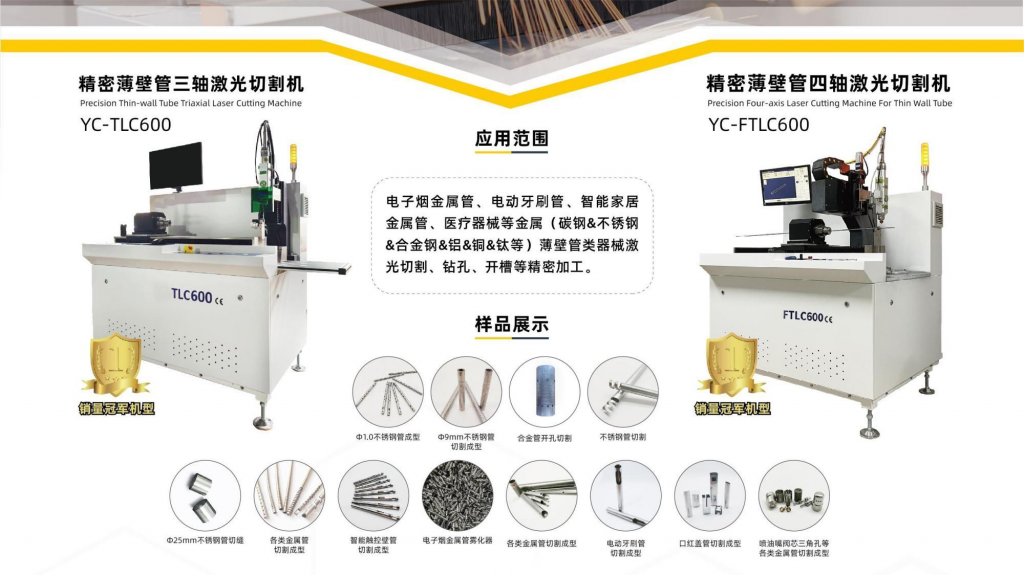

There are many subdivisions of stent laser cutting, which can be roughly divided into precision instrument processing and large-scale material processing. Large pipe processing generally has a clear demand for processing format, while laser cutting machines for precision instruments do not have the concept of processing format. They prefer processing technology, precision and efficiency.

There are many kinds of laser cutting machines on the market. Taking MEN as an example, we are a manufacturer of laser cutting machines for precision instruments. The product line is widely used in medical, electronic and other industries.

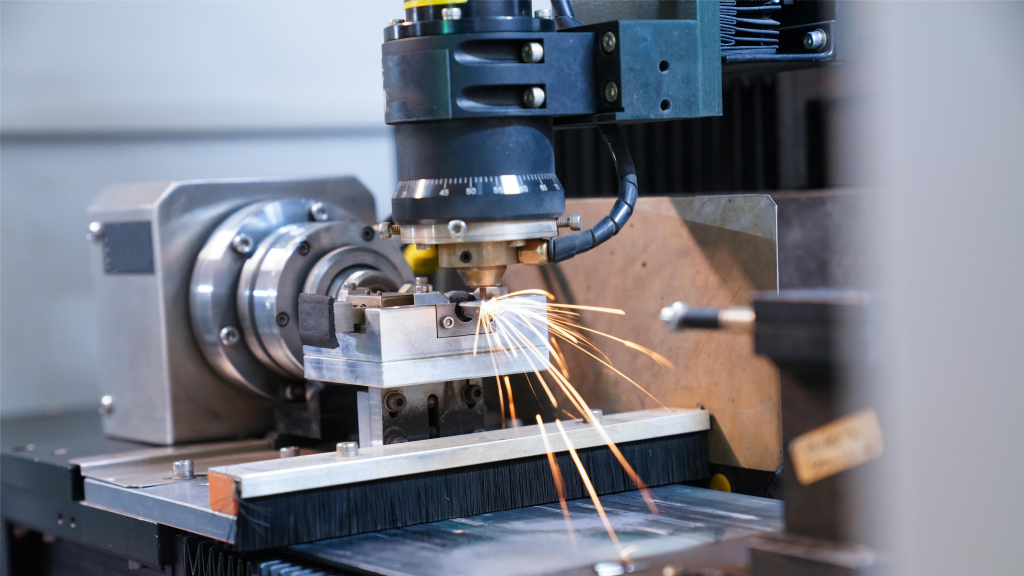

Laser cutting machine

The simple three-axis laser cutting machine TLC600 for thin-walled tubes in the field of electronic devices.

Femtosecond laser cutting machine

The ultra fast femtosecond laser cutting machine FSLC500, which is used for processing high-end medical devices such as neural interventional stents.

In addition to the better processing accuracy, the latter is also equipped with a visual monitoring system to monitor the dynamic state of laser processing in real time and support infrared&green light processing mode.

Of course, this is customized for the processing needs of medical devices. Most electronic devices do not have such a high demand.

Therefore, the price of a laser cutting machine is ultimately closely related to the processing demand. What kind of laser is equipped, ordinary fiber or femtosecond laser. And so on.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of laser cutting machine in precision alloy instrument processing 2025-04-24

Precision alloys (such as titanium alloy, nickel-based high-temperature alloy, medical stainless steel, etc.) are widely used in aerospace, medical equipment and precision instruments due to their high strength, corrosion resistance and biocompatibility. Laser cutting technology…

Breakthrough application of laser cutting machine in processing hard and brittle materials 2025-04-24

Hard and brittle materials (such as glass, ceramics, sapphire, single crystal silicon, etc.) are widely used in electronics, optics, semiconductors and other fields due to their high hardness and wear resistance. However, their high brittleness and easy cracking make traditional…

Application of precision laser cutting machines in watchmaking 2025-04-24

In the watchmaking industry that pursues extreme precision and artistic aesthetics, laser cutting machines have become a key process for the manufacture of core components of high-end watches with their non-contact, high-precision and flexible processing characteristics, and hav…

Laser cutting machine manufactures precision flexible circuit boards 2025-04-24

Flexible circuit boards (FPCs) are core components of electronic products such as wearable devices and foldable screen mobile phones. Their micron-level lines and special-shaped contours place strict demands on processing accuracy. Laser cutting technology, with its non-contact …