Application of precision laser cutting machines in watchmaking

(Click 109 )In the watchmaking industry that pursues extreme precision and artistic aesthetics, laser cutting machines have become a key process for the manufacture of core components of high-end watches with their non-contact, high-precision and flexible processing characteristics, and have promoted the upgrading of the traditional watchmaking industry towards digitalization and miniaturization.

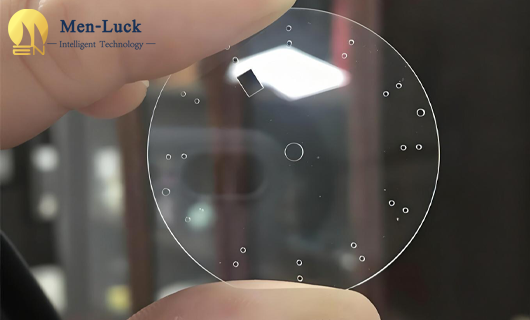

Core components such as watch gears and escape wheels are small in size, and traditional mechanical processing is prone to deformation or burrs. Laser cutting can achieve 0.01mm precision cutting on materials such as stainless steel and titanium alloys by focusing micron-level beams. The incision is smooth and free of thermal damage, ensuring the stability of part operation.

Laser cutting provides possibilities for artistic designs such as hollow dials and carved splints. Through digital programming, complex patterns or hollow structures can be etched on a 0.2mm thick K gold dial, and there is no chipping on the edge.

From 316L stainless steel to ceramics and sapphire, laser cutting can adapt to multiple materials of watches. Precision laser cutting machines drill and cut ceramic watch cases to avoid the risk of fragmentation of traditional tools, and improve processing efficiency by more than 50%. At the same time, laser cutting machines support rapid changeover in mass production. A single device can complete the standardized processing of thousands of parts per day, reducing the cost of manual intervention.

Laser cutting technology reshapes the watchmaking paradigm with “micron-level precision” and “artistic processing”, becoming the technical cornerstone of high-end watch quality and innovation.

WhatsApp:

WhatsApp: Wechat

Wechat

Femtosecond laser cutting machine reshapes the limit of ultra-precision manufacturing 2025-07-08

In the field of cutting-edge manufacturing that pursues micron or even nanometer precision, traditional processing methods have gradually reached physical limits. The emergence of femtosecond laser cutting machines, with its revolutionary "cold processing" characteristics brough…

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…