Breakthrough application of laser cutting machine in processing hard and brittle materials

(Click 77 )Hard and brittle materials (such as glass, ceramics, sapphire, single crystal silicon, etc.) are widely used in electronics, optics, semiconductors and other fields due to their high hardness and wear resistance. However, their high brittleness and easy cracking make traditional mechanical processing face huge challenges. Laser cutting machines provide efficient and low-loss solutions for hard and brittle materials through non-contact processing and precise energy control, promoting the upgrading of related industries.

Traditional wheel cutting or CNC processing is prone to produce microcracks or edge collapse on the surface of glass and ceramics, resulting in a yield of less than 60%. Laser cutting uses femtosecond/picosecond ultrafast pulse lasers to form an extremely narrow heat-affected zone inside the material, with a smooth and flat incision and an edge collapse size of less than 10μm. For example, the curved glass cover of smartphones is cut by ultraviolet laser, and the edge strength is increased by 40%, meeting the demand for precision appearance of 3C products.

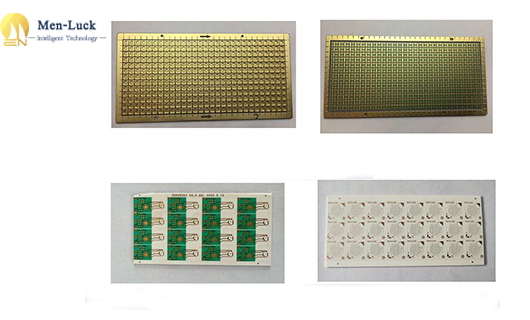

Laser cutting can break through the structural limitations of hard and brittle materials and realize micro-holes, curves and three-dimensional special-shaped processing. In the field of Micro LED, laser technology can cut a 50μm diameter microhole array on a 0.2mm thick sapphire substrate with an accuracy of ±2μm. In addition, the fine grooving and segmentation of ceramic circuit substrates also rely on laser processing to avoid stress damage of traditional board splitters.

From photovoltaic silicon wafers to aerospace ceramic coatings, laser cutting adapts to different materials through intelligent adjustment of wavelength and power. For example, the cutting speed of picosecond laser for aluminum nitride ceramics can reach 300mm/s, which is 5 times more efficient than traditional processes and has no tool loss.

As a professional laser equipment manufacturer, MenLuck focuses on the research and development of high-precision laser cutting equipment, providing customized solutions for 200+ segmented scenarios such as 3C electronic precision structural parts, medical surgical instruments, home appliance hardware and other high-precision processing. Welcome to contact us if you have any needs: E-mail: info@menlaser.com

WhatsApp:

WhatsApp: Wechat

Wechat

Femtosecond laser cutting machine reshapes the limit of ultra-precision manufacturing 2025-07-08

In the field of cutting-edge manufacturing that pursues micron or even nanometer precision, traditional processing methods have gradually reached physical limits. The emergence of femtosecond laser cutting machines, with its revolutionary "cold processing" characteristics brough…

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…