Product Model

YC-FCH50-C-A

YC-FCH80-C-A

YC-FCH80-C-B

Product Characteristics

- It is suitable for the application of nanosecond, picosecond and femtosecond laser fine machining with infrared laser power less than 1500W and UV & green laser power less than 100W;

- Modular design, focusing lenses & protective lens of focusing lens & cutting nozzle module can be separated and installed with CCD coaxial monitoring & Mirror & laser incidence interface module, compatible with soft and hard optical system, seamless connection;

- It supports straight through & 90 ° turning coaxial CCD installation, real-time monitoring processing status function, independent monitoring interface & clear picture & no jamming;

- Equipped with collimation protection lens, support the quick change function of the installation module of the focus lens protection lens with the focal length of 80mm and above;

- Compatible with 40 ~ 120mm focus lens, the maximum range of focus lens adjustment is 3mm;

- Compatible with QBH and QCS laser output head interface, pointed and flat cutting nozzle;

- It provides 1 ~ 4 gas access interfaces, to withstand the peak pressure of 2.5MPa;

- The sealing protection grade is IP65;

- The structure is compact, light and convenient for disassembly and installation.

Product Parameters

Technical indicators

| Model | Focal length | Fotutingmirroradjusment range | Cutting nuzzle aperture | Withstand peak power | Number of process gas paths | Withstand peak pressure | Degree of protection | dead weight |

|---|---|---|---|---|---|---|---|---|

| GZH-FCH50-A | 40mm~60mm optional | 0~3mm | 0.3mm~0.8mm optional | 1500W | 1~4 for selection | 2.0Mpa | IP55 | 1.2kg |

| GZH-FCH50-C-A | 40mm~60mm optional | 0~3mm | 0.3mm~0.8mm optional | 1500W | 1~4 for selection | 2.0Mpa | IP55 | 4kg |

| GZH-FCH50-C-B | 40mm~60mm optional | 0~3mm | 0.3mm~0.8mm optional | 1500W | 1~4 for selection | 2.0Mpa | IP55 | 4kg |

| GZH-FCH80-C-A | 80mm | 0~3mm | 0.3mm~0.8mm optional | 1500W | 1~4 for selection | 2.0Mpa | IP55 | 4kg |

| GZH-FCH80-C-B | 80mm | 0~3mm | 0.3mm~0.8mm optional | 1500W | 1~4 for selection | 2.0Mpa | IP55 | 4kg |

| GZH-FCH80-C-C | 80mm | 0~3mm | 1 0,3mm~0.8mm optional | 1500W | 1~4 for selection | 2.0Mpa | IP55 | 4kg |

| GZH-FCH120-A | 80mm | 0~3mm | 0.3mm~0.8mm optional | 1500W | 1~4 for selection | 2.0Mpa | IP55 | 1.5kg |

configuration options

| Model | CCD coaxial visual monitoring CCD right angle switching Visual monitoring |

Optional QBH interface | Optional QCS interface | Optional flat head cutting nozzle | Optional tip cutting nozzle | Modular disassembly and assembly of protective lens | Optional soft and hard optical path | Split focusing lens group | Optional swing function |

|---|---|---|---|---|---|---|---|---|---|

| GZH-FCH50-A | no | no | Yes | Yes | Yes | Yes | no | no | no |

| GZH-FCH50-C-A | Yes | no | no | Yes | Yes | Yes | no | no | no |

| GZH-FCH50-C-B | Yes | no | no | Yes | Yes | Yes | Yes | no | no |

| GZH-FCH80-C-A | Yes | no | no | Yes | Yes | Yes | Yes | Yes | Yes |

| GZH-FCH80-C-B | Yes | no | no | Yes | Yes | Yes | Yes | Yes | Yes |

| GZH-FCH80-C-C | no | Yes | no | Yes | Yes | Yes | Yes | no | Yes |

| GZH-FCH120-A | no | no | no | Yes | Yes | Yes | no | no | no |

Delivery and Warranty

| Model | quantity | Company/set | Delivery date/week | quality guarantee period/month |

|---|---|---|---|---|

| GZH-FCH50-A | 1 | set | 8~10 week | 12 month |

| GZH-FCH50-C-A | 1 | set | 8~10 week | 12 month |

| GZH-FCH50-C-B | 1 | set | 8~10 week | 12 month |

| GZH-FCH80-C-A | 1 | set | 8~10 week | 12 month |

| GZH-FCH80-C-B | 1 | set | 8~10 week | 12 month |

| GZH-FCH80-C-C | 1 | set | 8~10 week | 12 month |

| GZH-FCH120-A | 1 | set | 8~10 week | 12 month |

Related articles

More popular products

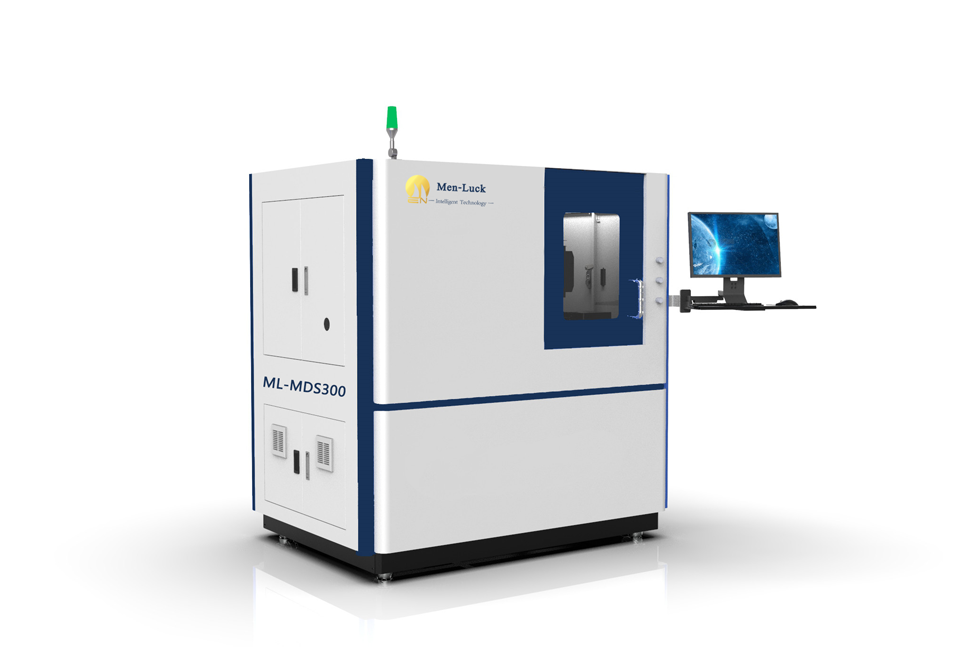

Laser Cutting Machine for Medical Big Stent ML-MDS300(Φ30)

Application Medical large stent laser cutting machine mainly uses heart valve, mitral valve, perip…

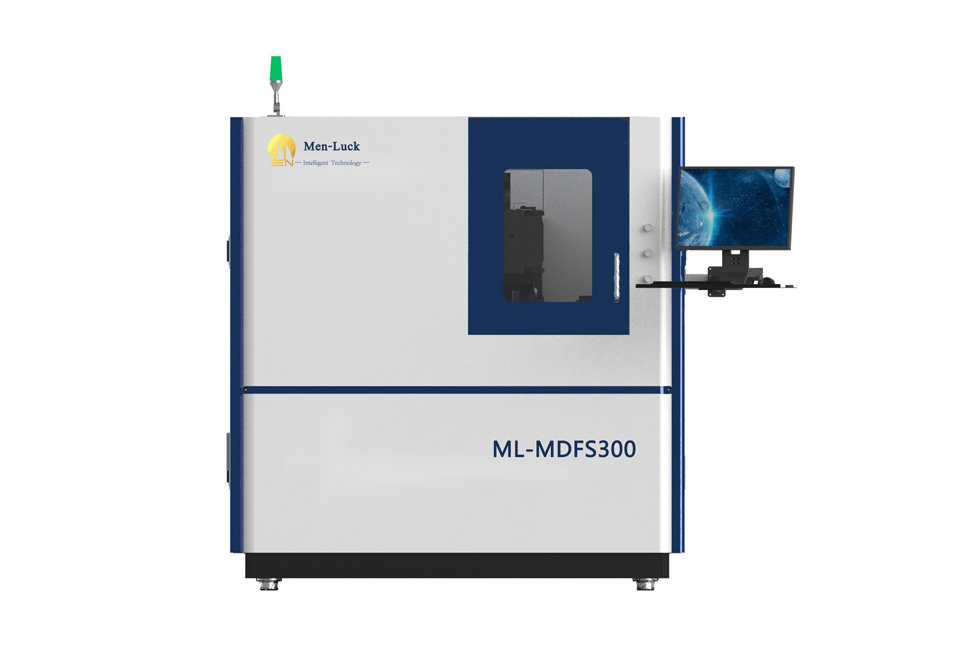

Laser Cutting Machine for Ultra Fast Femtosecond Stent (three axis & infrared & green light) ML-MDFS300

Application Super fast femtosecond stent laser cutting machine is mainly used for intracranial thr…

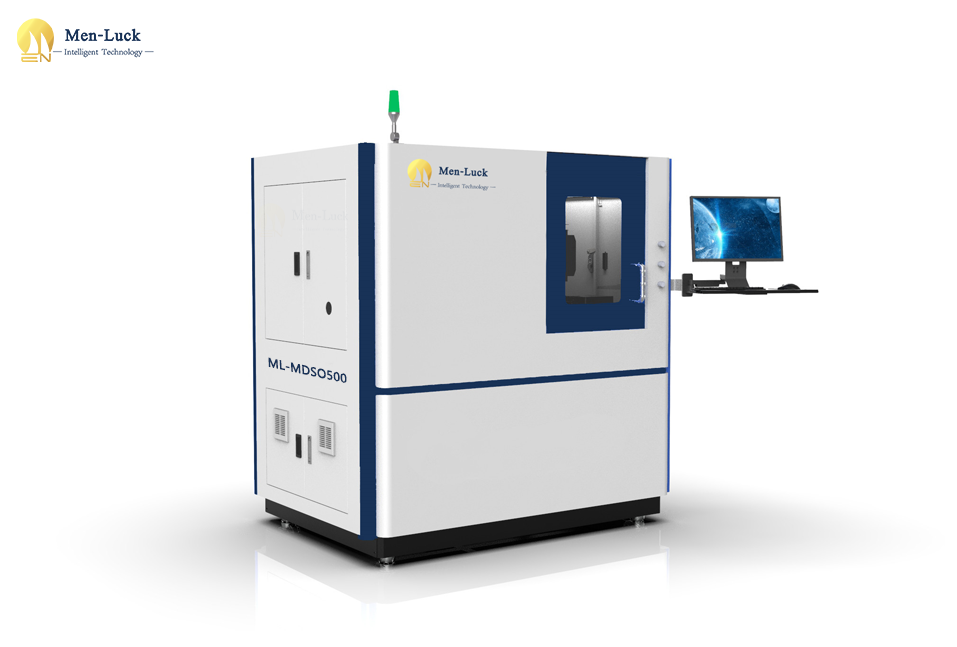

Laser Cutting Machine for Precision Stainless Steel Instruments ML-MDSO500

Application Laser micromachining of drilling & blind slotting & cutting of stainless steel…

WhatsApp:

WhatsApp:

Wechat

Wechat

Application of precision laser welding in medical device manufacturing 2024-07-25

With the advancement of medical technology, the medical industry has higher and higher requirements for the quality and precision of medical devices. As an efficient and precise welding technology, precision laser welding plays an increasingly important role in the manufacture o…

UV laser marking machines are favored by the medical device industry 2024-07-22

Plastic laser marking has been widely used in industrial equipment, medical devices, aerospace components, automotive parts and ordinary household appliances. However, medical device manufacturing suppliers need to use unique device identification codes, data matrices and other …

Laser Cutting Machines: The Future of Medical Device Manufacturing 2024-07-18

With the development of science and technology, medical equipment manufacturing is also constantly improving.Precision medical laser cutting machines have become a powerful force in medical equipment manufacturing with their unique technical advantages and wide applicability. Wi…