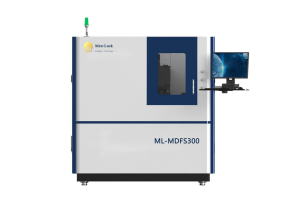

Equipment parameters

| Maximum operating speed | 300mm/s(X);100mm/s(Z);600rpm(θ) |

|---|---|

| Positioning accuracy | ±2um(X);±3um(Z);±15arcsec(θ) |

| Repetitive positioning accuracy | ±0.5um(X);±1um(Z);±3arcsec(θ) |

| Cutting seam width | 15um~25um |

| Machining material | 304&316L&Ni-Ti&L605 etc. |

| Tube blank length | < 2.5m (support fixture can be customized); |

| Laser type | Fiber laser |

| Processing wall thickness | 0~0.5±0.02 mm |

| Processing tube diameter | Φ0.1~Φ7.5&Φ0.3~Φ16.0±0.02 mm; |

| Tailing length | 60mm |

| Single processing range | 0~300mm (longer products can be processed by segmented splicing method); |

| Laser type | Fiber laser |

| Laser wavelength | 1030-1070±10nm |

| laser power | 100W&200W&250W&300W&500W for option |

| Equipment power supply | 220V± 10%, 50Hz;AC 25A (main circuit breaker) |

| File format | DXF&DWG |

| Equipment dimensions | 1200mmx1300mmx1700mm |

| Equipment weight | 1500Kg |

Strong adaptability

- Have the ability of laser dry cutting & wet cutting & drilling & slotting and other fine machining technology

- Support machining of radial opening feature of equal diameter tube

- Can machine 304 & 316L & Ni-Ti & L605 etc. materials

- Can aachine equal diameter tube & deformed tube & semi-finished tube &small format plane instrument

- Adopt the combined precision thin-walled tube shaft sleeve support system with self-adaptive shape tolerance variation

- Compatible with precision D-type chuck & ER series chuck & three-jaw chuck and other precision thin-walled tube clamping system

- Provide the matching scheme of precision thin-walled tube continuous automatic feed machining & automatic loading and unloading

- Equipped with self-developed 2D & 2.5D & 3D CAM software system for laser micromachining

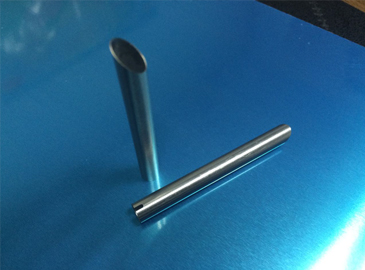

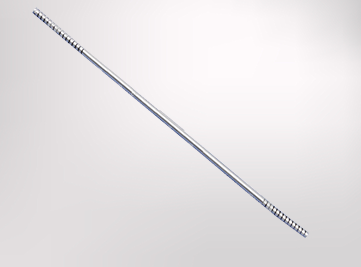

Sample display

Φ6.4mm pediatric puncture tube

Φ4.0 mm puncture tube fittings

Microtube cutting

Slotting of puncture needle tube in orthopedics department

Pinhole opening

Sample of surgical instruments

Flexible design

- Follow the design concept of ergonomics, delicate and concise

- Can process 304 & 316L & Ni-Ti & L605 and other alloy materials

- Provide the optional function of machine vision system to real time online monitor the laser dynamic machining process

- The software and hardware functions match flexibly, support personalized function configuration & intelligent production management

- Support forward innovative design from component level to system level

- Open type control & laser micromachining software system is easy to operate & intuitive interface

More popular products

Precision fiber laser welding machine

Application Precision fiber laser welding machine is a high-precision and high-efficiency welding …

Precision Fiber laser marking machine

Application Fiber optic marking machine takes advantage of long pulse width to realize marking pro…

Laser Cutting Machine for Medical Big Stent M…

Application Medical large stent laser cutting machine mainly uses heart valve, mitral valve, perip…

UltraFast Femtosecond Laser Cutting Machine F…

Application Super fast femtosecond stent laser cutting machine is mainly used for intracranial thr…

WhatsApp:

WhatsApp: Wechat

Wechat