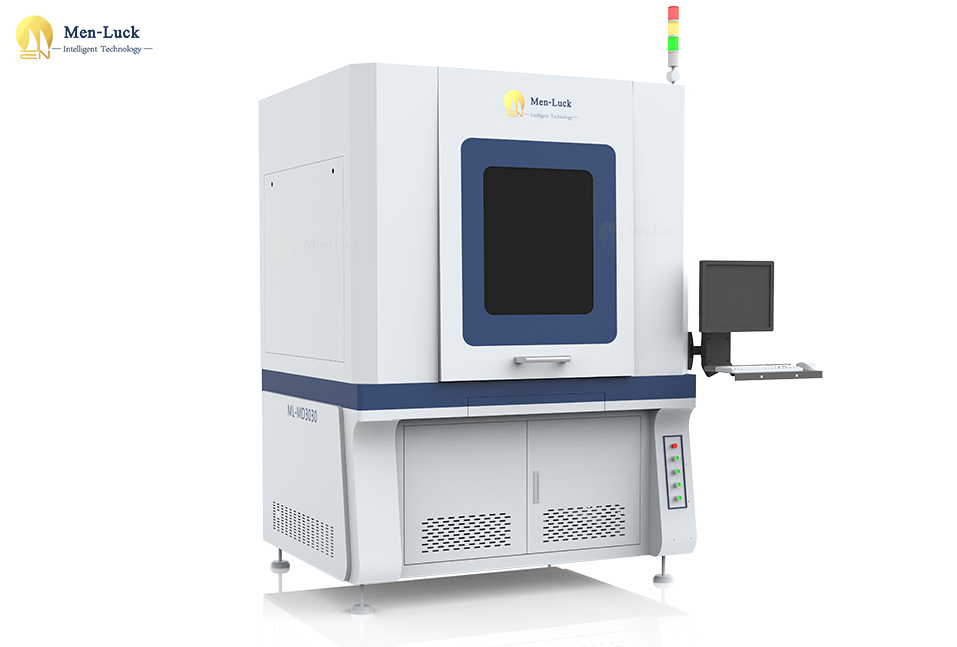

Equipment parameters

| Maximum operating speed | 1000mm/s(X) ;1000mm/s(Yl&Y2) ;50mm/s(Z); |

|---|---|

| Positioning accuracy | ±3um (X) ±3um (Y1&Y2) ;±5um (Z); |

| Repetitive positioning accuracy | ±1um(X) ;±1um (Y1&Y2) ;±3um(Z); |

| Machining material | stainless steel & hard alloy steel & Ceramics & Aluminum & Copper & magnesium aluminum alloy |

| Plane machining range | 300mm*300mm |

| Material wall thickness | 0~1.5±0.02 mm; |

| Laser type | Fiber Laser |

| Laser wavelength | 1030-1070±10nm; |

| Laser power | CW100W&200W&300W&QCW150W&450W for option |

| Equipment power supplyr | 220V± 10%, 50Hz;AC 20A (main circuit breaker) |

| File format | DXF、DWG |

| Equipment dimensions | 1200mm*1300mm*1600mm |

| Equipment weight | 1200Kg |

Strong adaptability

- Have the ability of laser cutting, drilling, blind slotting, marking and other fine machining technology for plane & curved surface instruments

- Can machine stainless steel, hard alloy steel, ceramics, aluminum alloy and other materials

- Equipped with a self-developed direct drive mobile double drive precision movement platform, granite platform, aluminum alloy granite beam for selection

- Provide the optional function, such as double station & Visual Positioning & automatic feeding and unloading system & dynamic monitoring etc.

- Equipped with self-developed long & short focal length, sharp nozzle & flat nozzle fine laser cutting head

- Equipped with modular material receiving and dust removal pipeline system

- Provide self-developed movable tension frame & fixed tension frame & vacuum adsorption & honeycomb plate, etc. optional fixture

- Equipped with the self-developed 2D & 2.5D & 3D CAM software system for laser micromachining

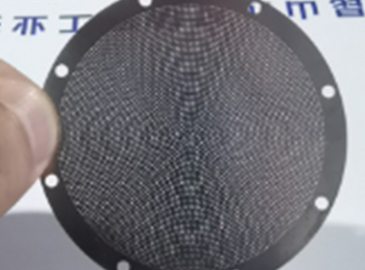

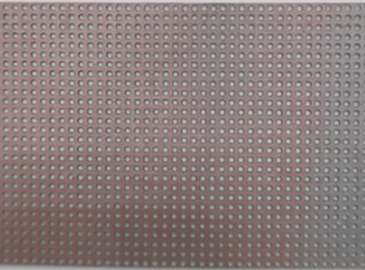

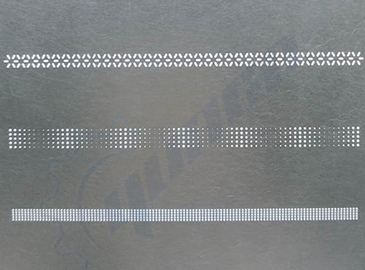

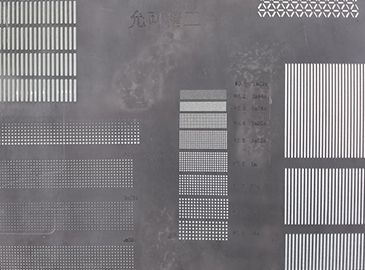

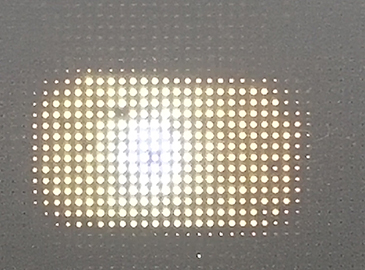

Sample display

SUS WT0.1-W30um-D50um blind slot

SUS WT0.6- Ø 0.05mm microhole

Ceramic WT0.6- Ø 0.06mm microhole

All kinds of holes on WT0.6mm aluminum plate

WT0.8mm magnesium aluminumplate Ø 0.1mm -Ø1mm various hole cutting

Stainless steel WT0.2mm-0.02mm microhole

Flexible design

- Follow the design concept of ergonomics, delicate and concise

- Flexible software & hardware function collocation, supporting personalized function configuration & intelligent production management

- Support positive innovation design from component level to system level

- Open control & laser micromachining software system easy to operate & intuitive interface

More popular products

Precision fiber laser welding machine

Application Precision fiber laser welding machine is a high-precision and high-efficiency welding …

Precision Fiber laser marking machine

Application Fiber optic marking machine takes advantage of long pulse width to realize marking pro…

Laser Cutting Machine for Medical Big Stent M…

Application Medical large stent laser cutting machine mainly uses heart valve, mitral valve, perip…

UltraFast Femtosecond Laser Cutting Machine F…

Application Super fast femtosecond stent laser cutting machine is mainly used for intracranial thr…

WhatsApp:

WhatsApp: Wechat

Wechat