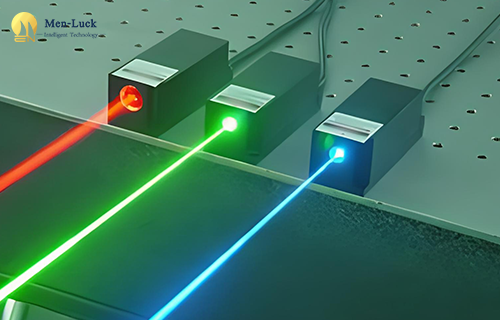

cutting machine manufacturers explain in detail the differences between ultraviolet, red light and green light sources?

(Click 187 )The most commonly used light sources for laser cutting machines are mainly red light, ultraviolet light, and green light. Each type of light source has different advantages. According to the characteristics, thickness and processing quality requirements of the processing material, choosing the appropriate laser source can become the most effective in laser cutting. Fast knife. The cutting principle of the laser cutting machine is to irradiate the surface of the material with a high-energy laser beam to melt, vaporize, and ablate the material to achieve cutting needs. The editor will explain to you the differences between the three light sources commonly used in laser cutting.

Fiber laser cutting machine light source red light

Fiber laser refers to a laser with rare earth element-doped glass fiber as the gain medium. It mainly uses red light as the light source. The working wavelength of red light is 1064nm. The fiber laser cutting machine achieves material cutting and processing through high energy density, with high precision and It has the advantages of fast running speed, strong flexibility, easy integration, high stability, and low processing cost. Fiber laser cutting machines have both large laser power and the ability to adapt to cutting and processing of a variety of materials. The materials that fiber laser cutting machines can cut include sapphire, aluminum substrates, ceramic substrates, copper substrates, PCB circuit boards and various metal alloy materials such as copper, zinc, nickel, stainless steel, aluminum alloy, tungsten steel, etc.

UV laser cutting machine light source: purple light:

Ultraviolet light source is also called cold light source, and its working wavelength is 355nm. The ultraviolet light spot is very small and has a special UM wavelength. The fiber laser and CO₂ laser cannot cut materials, but the ultraviolet laser can, and enjoys the reputation of being all-round in the traditional processing field. UV laser cutting machines can be used for laser marking, laser cutting and laser welding processes. UV laser can cut cover films, FPC soft boards, PCB soft and hard boards, FPC auxiliary materials, ultra-thin metals, ceramics, polymer materials, resins, silicon wafers and PET/PI/PP films with high quality. Not only the cutting surface is smooth and flat , and has high cutting efficiency and is widely used in the field of micro-machining.

Green light laser cutting machine light source:

The wavelength of green light is 532 nanometers. Its spot is small and the focal length is shorter. It belongs to the cold processing mode and plays an irreplaceable role in precision cutting. The light source of men-luck femtosecond laser cutting machine mainly uses ultraviolet light and green light. They can often be seen especially in industries such as circuit boards, glass, ceramics, jewelry, and glasses. Applicable materials for green light: precision cutting of cover film, FPC soft board, PCB soft and hard board, PET/PI/PP and other flexible films, ultra-thin glass, ceramic substrate and other materials.

From the above men-luck’s introduction to light sources, we can know that fiber laser cutting machines are mainly used in the metal materials industry. UV laser cutting machines focus on FPC soft board cutting, IC chip cutting and some ultra-thin metal cutting; green light laser cutting machines are used in In the PCB field, we mainly cut PCB hard boards. Laser micromachining for different applications requires the use of suitable lasers and light sources. If you have proofing needs, please contact men-luck. We can do free sample proofing testing and provide equipment customization services according to your needs.

WhatsApp:

WhatsApp:

Wechat

Wechat

Men-Luck has came to the HANNOVER MESSE 2024-04-26

It is reported that the 2024 Hannover MESSE in Germany has more than 1,000 Chinese enterprises participating in the sea, the scale of the exhibition is second only to the host Germany, and Chinese enterprises are accelerating their integration into the global industrial chain sy…

Ultraviolet laser cutting copper foil 2024-04-18

Metal foil is a thin sheet extended by metal, and ultra-thin metal foil has a variety of applications in various industries. Titanium foil can be used in loudspeaker components and medical equipment enclosures; Materials such as tungsten and molybdenum can be used for electronic…

The 2024 Munich laser world of photonics was successfully concluded 2024-03-22

In March 2024, the three-day Munich laser world of photonics has come to a perfect end in Shanghai, which has been held in Shanghai since 2006. As an important annual event for the laser, optical and photoelectric industries in Asia, the new edition of the fair covers the photoe…

Laser marking machine and 3C electronics industry close combination 2024-03-21

In the era of rapid development of science and technology, laser marking machine, as a high-precision processing equipment, has gradually become an indispensable processing link in the 3C electronics industry. In simple terms, it is the use of high energy density laser beams to …