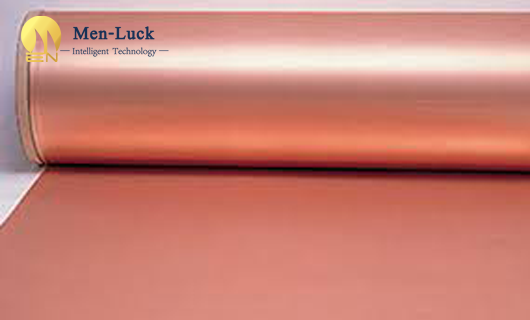

Ultraviolet laser cutting copper foil

(Click 152 )Metal foil is a thin sheet extended by metal, and ultra-thin metal foil has a variety of applications in various industries. Titanium foil can be used in loudspeaker components and medical equipment enclosures; Materials such as tungsten and molybdenum can be used for electronic tubes and heating components; Fe-ni soft magnetic alloy foil can be used to fabricate the core of micro high frequency pulse transformer and magnetic recorder. Copper foil can be used for copper clad laminates. men-luck’s UV laser cutting machines can meet the high precision machining requirements of various metal foils.

Copper clad laminate is an electronic glass fiber cloth or other reinforcing material dipped in resin, one or two sides covered with copper foil and hot pressed and made of a plate-like material, referred to as copper clad plate. A variety of different forms and functions of the printed circuit board are made by etching, drilling and other processes on the copper-clad plate. Copper foil has functions such as interconnection and support in printed circuit boards, which directly affects the performance and quality of printed circuit boards. Due to the high manufacturing cost and difficulty of copper foil, not only high precision is required in the cutting process, but also improve the utilization rate and reduce the production cost. Compared with the traditional die cutting process, the UV laser cutting machine is superior in processing efficiency, cutting loss and precision.

At present, the industry generally uses ultraviolet laser cutting machine to cut copper foil. It has micron-level cutting accuracy, and can achieve high-quality cutting results by setting parameters such as focus position, size and power, so that the cutting slit is small and the edge is smooth. In addition, the wavelength of the ultraviolet laser is short, the material is widely applicable, has a high absorption rate, and the extremely short pulse width in the process of “cold processing” has little influence on the thermal deformation around the processing surface, so there will be no carbonization or burr phenomenon when the copper foil is cut. It can be said that ultraviolet laser cutting machine has become an important equipment in the field of precision cold processing.

With the rapid development of various industries, copper foil as the basic material of copper clad laminate, the demand market continues to expand. The ultraviolet laser cutting machine developed by MEN-LUCK can achieve high-precision and high-efficiency cutting, drilling, engraving, to meet the needs of various industries for ultra-thin metal non-metallic processing, is the ideal equipment for fine processing industry. Customers are welcome to contact us.

WhatsApp:

WhatsApp:

Wechat

Wechat

Men-Luck has came to the HANNOVER MESSE 2024-04-26

It is reported that the 2024 Hannover MESSE in Germany has more than 1,000 Chinese enterprises participating in the sea, the scale of the exhibition is second only to the host Germany, and Chinese enterprises are accelerating their integration into the global industrial chain sy…

The 2024 Munich laser world of photonics was successfully concluded 2024-03-22

In March 2024, the three-day Munich laser world of photonics has come to a perfect end in Shanghai, which has been held in Shanghai since 2006. As an important annual event for the laser, optical and photoelectric industries in Asia, the new edition of the fair covers the photoe…

Laser marking machine and 3C electronics industry close combination 2024-03-21

In the era of rapid development of science and technology, laser marking machine, as a high-precision processing equipment, has gradually become an indispensable processing link in the 3C electronics industry. In simple terms, it is the use of high energy density laser beams to …

Application of laser drilling machine in photovoltaic industry 2024-03-18

Laser drilling uses a high-energy-density laser beam to locally heat the material to a high enough temperature to evaporate, melt or vaporize it to form holes. The key to laser drilling lies in precise control of energy density, line speed and focus position to achieve precise p…