Application of precision laser cutting machines in watchmaking

(Click 80 )In the watchmaking industry that pursues extreme precision and artistic aesthetics, laser cutting machines have become a key process for the manufacture of core components of high-end watches with their non-contact, high-precision and flexible processing characteristics, and have promoted the upgrading of the traditional watchmaking industry towards digitalization and miniaturization.

Core components such as watch gears and escape wheels are small in size, and traditional mechanical processing is prone to deformation or burrs. Laser cutting can achieve 0.01mm precision cutting on materials such as stainless steel and titanium alloys by focusing micron-level beams. The incision is smooth and free of thermal damage, ensuring the stability of part operation.

Laser cutting provides possibilities for artistic designs such as hollow dials and carved splints. Through digital programming, complex patterns or hollow structures can be etched on a 0.2mm thick K gold dial, and there is no chipping on the edge.

From 316L stainless steel to ceramics and sapphire, laser cutting can adapt to multiple materials of watches. Precision laser cutting machines drill and cut ceramic watch cases to avoid the risk of fragmentation of traditional tools, and improve processing efficiency by more than 50%. At the same time, laser cutting machines support rapid changeover in mass production. A single device can complete the standardized processing of thousands of parts per day, reducing the cost of manual intervention.

Laser cutting technology reshapes the watchmaking paradigm with “micron-level precision” and “artistic processing”, becoming the technical cornerstone of high-end watch quality and innovation.

WhatsApp:

WhatsApp: Wechat

Wechat

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …

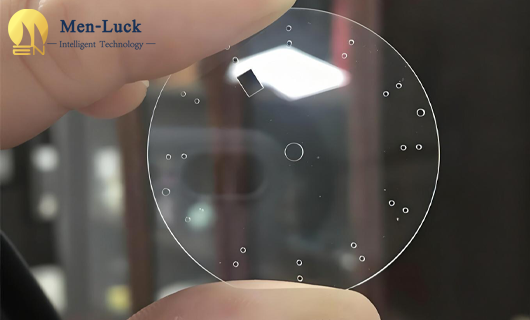

Core application of laser cutting machine in glass photoelectric encoder manufacturing 2025-06-03

As the core component of high-precision angle sensor, the processing quality of the transparent grid of glass photoelectric encoder directly affects the measurement accuracy and signal stability. Laser cutting technology breaks through the bottleneck of traditional processes wit…