What are the types of laser cutting

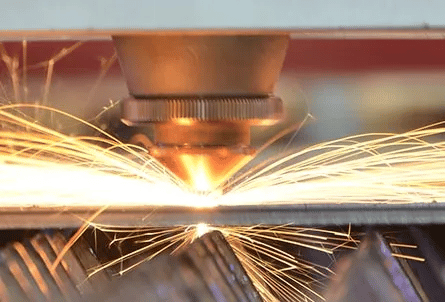

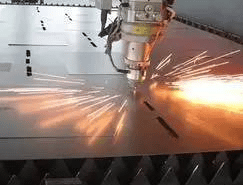

(Click 897 )Laser cutting is a non-contact processing method with high energy and good density controllability. The laser beam is focused to form a spot with high energy density, which has many characteristics when applied to cutting. There are four different ways of laser cutting to deal with different situations.

1.Laser melting cutting

In laser melting and cutting, the workpiece is partially melted, and then the melted material is ejected by air flow. Because the transfer of materials only occurs in their liquid state, this process is called laser melting and cutting.

The laser beam coupled with high-purity inert cutting gas makes the melted material leave the kerf, while the gas itself does not participate in the cutting. Laser melting cutting can achieve higher cutting speed than gasification cutting. The energy required for gasification is usually higher than the energy required to melt the material. In laser melting and cutting, the laser beam is only partially absorbed. The maximum cutting speed increases with the increase of laser power, and decreases almost inversely with the increase of plate thickness and material melting temperature. When the laser power is fixed, the limiting factor is the air pressure at the kerf and the thermal conductivity of the material. Laser melting and cutting can obtain oxidation free notch for iron materials and titanium metals. Laser power density producing melting but not gasification.

2.Laser gasified cutting

In the process of laser gasification cutting, the speed at which the material surface temperature rises to the boiling point temperature is fast enough to avoid melting caused by heat conduction, so that part of the material vaporizes into steam and disappears, and part of the material is blown away from the bottom of the cutting seam by the auxiliary gas flow as ejecta. In this case, very high laser power is required.

In order to prevent material vapor from condensing on the slit wall, the thickness of the material must not exceed the diameter of the laser beam. This process is therefore only suitable for applications where the exclusion of molten material must be avoided. In fact, this processing is only used in a small area of iron base alloy.

This process cannot be used for materials, such as wood and some ceramics, which have no melting state and are unlikely to allow the material vapor to condense again. In addition, these materials are usually required to achieve a thicker cut. In laser gasification cutting, the optimal beam focusing depends on the material thickness and beam quality. Laser power and heat of vaporization have only certain effects on the optimal focus position. The maximum cutting speed is inversely proportional to the gasification temperature of the material when the thickness of the plate is fixed. The required laser power density is greater than 108W/cm2 and depends on the material, cutting depth and beam focus position. Under the condition that the thickness of the plate is fixed, assuming that there is sufficient laser power, the maximum cutting speed is limited by the gas jet speed.

3.Control fracture cutting

For brittle materials that are easy to be damaged by heat, high-speed and controllable cutting by laser beam heating is called controlled fracture cutting. The main content of this cutting process is that the laser beam heats a small area of brittle material, causing large thermal gradient and serious mechanical deformation in the area, leading to the formation of cracks in the material. As long as a uniform heating gradient is maintained, the laser beam can guide the generation of cracks in any desired direction.

4.Oxidation melting cutting

Inert gas is generally used for melting and cutting. If oxygen or other active gases are used instead, the material will be ignited under the irradiation of laser beam, which will produce another heat source through violent chemical reaction with oxygen to further heat the material, which is called oxidation melting and cutting.

Because of this effect, for structural steel with the same thickness, the cutting rate obtained by this method is higher than that by melting cutting. On the other hand, this method may have poorer notch quality than melt cutting. In fact, it will generate wider kerf, obvious roughness, increased heat affected zone and worse edge quality. Laser flame cutting is not good for machining precision models and sharp corners (there is a risk of burning off sharp corners). Pulse mode laser can be used to limit the thermal effect, and the laser power determines the cutting speed. When the laser power is fixed, the limiting factor is the oxygen supply and the thermal conductivity of the material.

WhatsApp:

WhatsApp: Wechat

Wechat

Advantages of laser cutting nickel-titanium electrode 2024-05-06

In recent years, with the continuous development of medical technology, medical laser cutting machines play an important role in the manufacture of nickel-titanium electrode sheets. Next, we will introduce the application and advantages of our Men-luck laser cutting machine in t…

Laser cutting process of eye lens 2024-04-11

With the increasing demand for vision correction in modern society, glasses, as a common optical instrument for vision correction, play an indispensable role in People's Daily life. Lens processing is a delicate process that requires cutting and punching to complete the manufact…

Ultrafast femtosecond laser technology helps cardiovascular stent manufacturing 2024-04-08

With the soaring incidence of cardiovascular and cerebrovascular diseases, stent implantation has become one of the main methods of surgical treatment. Compared with traditional cutting equipment, medical laser cutting machine not only has good cutting quality, high cutting prec…

Application of laser cutting machine in mobile phone camera module manufacturing 2024-04-04

With the continuous progress of science and technology and the improvement of people's requirements for quality of life, the fields of smart wear, smart home, automotive electronics and mobile phone consumer electronics have been vigorously developed. In these fields, the camera…