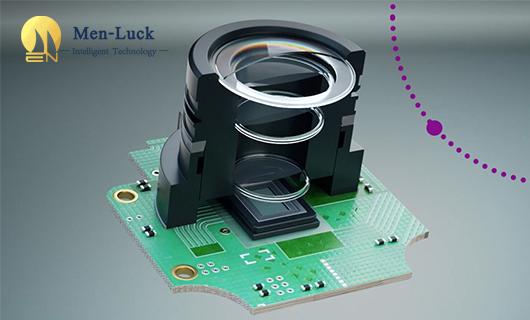

Application of laser cutting machine in mobile phone camera module manufacturing

(Click 168 )With the continuous progress of science and technology and the improvement of people’s requirements for quality of life, the fields of smart wear, smart home, automotive electronics and mobile phone consumer electronics have been vigorously developed. In these fields, the camera module as an important accessory shows a diversified development trend. Especially driven by applications represented by smartphones, the camera module industry has ushered in new growth opportunities. In order to ensure the consistency of the camera photo effect, laser cutting in the mobile phone camera module manufacturing process for accurate cutting is crucial, not only requires smooth cutting surface, high cutting accuracy, and high cutting efficiency.

Laser cutting machine, as the necessary equipment for laser processing of camera module, plays an important role in the field of camera module manufacturing. The laser cutting machine uses a laser beam with high energy density, good monochromity, good coherence and strong directivity to cut the camera module, and adopts non-contact cutting, which has no processing stress on the surface or internal material of the camera module and no yellowing or blackness and other problems to ensure that the performance of the camera module is not affected. The principle of laser cutting machine is to convert electrical energy into radiant energy, and through the amplifier to increase its output power to form a continuous or pulsed radiation source within a certain spectrum range.

Laser cutting machine phase has advantages that traditional processing equipment does not have. First, the laser beam has a very high focusing force and precise control ability, which can be processed with micron accuracy; Secondly, because the laser cutting machine uses a non-contact processing method, it ensures the integrity of the product and the stability of the performance, avoiding the risk of damage that may be caused by traditional machining. The laser cutting machine uses the powerful laser beam after focusing to achieve accurate, fast and non-damaging processing of various materials, so as to meet the needs of the mobile phone camera module for complex structure and small size parts, which is difficult to do using traditional processing methods.

MEN-LUCK supports personalized customization of precision laser cutting machine, such as configuring automatic up and down equipment according to customer needs, precision cutting, and can also provide customers with proofing services and provide a variety of micro-machining technology solutions, welcome new and old customers to consult and negotiate business!

WhatsApp:

WhatsApp:

Wechat

Wechat

Advantages of laser cutting nickel-titanium electrode 2024-05-06

In recent years, with the continuous development of medical technology, medical laser cutting machines play an important role in the manufacture of nickel-titanium electrode sheets. Next, we will introduce the application and advantages of our Men-luck laser cutting machine in t…

Laser cutting process of eye lens 2024-04-11

With the increasing demand for vision correction in modern society, glasses, as a common optical instrument for vision correction, play an indispensable role in People's Daily life. Lens processing is a delicate process that requires cutting and punching to complete the manufact…

Ultrafast femtosecond laser technology helps cardiovascular stent manufacturing 2024-04-08

With the soaring incidence of cardiovascular and cerebrovascular diseases, stent implantation has become one of the main methods of surgical treatment. Compared with traditional cutting equipment, medical laser cutting machine not only has good cutting quality, high cutting prec…

Metal laser tube cutting machine for furniture industry to reduce production costs 2024-04-01

The metal laser tube cutting machine can cut and punch various types of metal tube materials such as metal round pipes and square pipes according to the needs of use, and the precision is high and the quality is good. In the current era of diversified and light luxury furniture,…