What are the precautions for air cooling and water cooling lasers?

(Click 915 )The laser in the laser cutting machine will generate a lot of heat during long-term operation. It is necessary to install a cooling system for cooling fan heat to maintain the temperature required for the laser to operate, thus ensuring the normal operation of the laser cutting machine.

Lasers used in precision laser cutting machines usually have two cooling methods: water cooling and air cooling.

The above two heat dissipation methods have one thing in common, that is, neither directly cools the discharge area that generates heat, but conducts the waste heat generated by the discharge area to the cooling liquid or the heat dissipation plate through conduction.

So, what is the difference between water cooling and air cooling?

Water cooling is equipped with a special water cooler. We usually use pure water, distilled water or deionized water as the cooling fluid (antifreeze can also be used in winter) to dissipate heat from the laser, and use the water cooler to keep the temperature of the machine constant, thus achieving stable laser light output. For the effect of quality, water cooling usually has a large cooling capacity, but the water cooler needs to be externally installed and cannot be installed in the laser cutting machine, and the equipment occupies a large area.

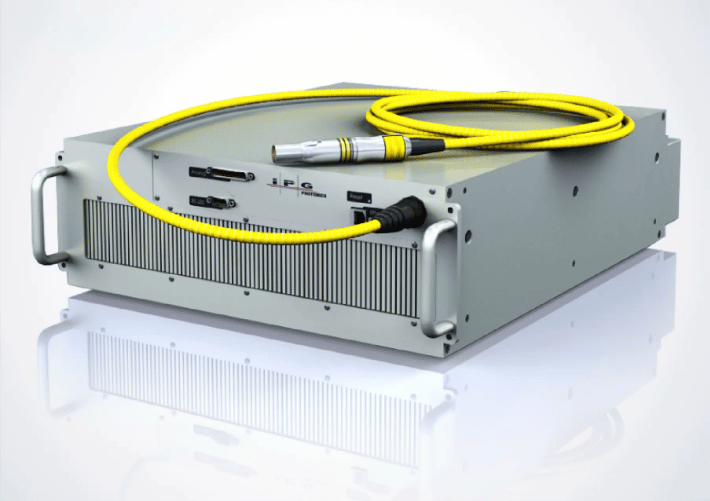

Air cooling is to let the machine dissipate heat through the built-in fan of the laser. Usually, the laser has its own fan, so it is built into the machine and occupies a smaller area. However, compared with water cooling, it is more difficult to maintain a constant low temperature.

Generally, air cooling heat dissipation can be used for low laser power, and water cooling heat dissipation is suitable for high laser power.

The cooling method of our company’s precision laser stent cutting machine is optional and can be customized according to the temperature of the customer’s location and customer According to the configuration requirements, it is recommended to use water cooling or air cooling.

Water cooling or air cooling laser cutting machines need to pay attention to the following matters during operation:

- In the case of high temperature thermal processing, anhydrous cooling may cause serious consequences.

- Whether it is a water cooling or air cooling laser cutting machine, the dirt inside the water tank or fan should be removed and a regular cleaning work should be done, which not only maintains the good operability of the laser cutting machine, but also improves the life of the equipment.

- The high temperature environment should be especially remembered during the use of the laser, and the ambient temperature should not be higher than 35 degrees Celsius as much as possible, otherwise it will also affect the precision of precision laser cutting.

- In the process of operation, if there is any abnormal phenomenon, the power must be turned off in time, and after the vibration mirror stops working, a series of inspections and maintenance should be carried out.

WhatsApp:

WhatsApp: Wechat

Wechat

Advantages of laser cutting nickel-titanium electrode 2024-05-06

In recent years, with the continuous development of medical technology, medical laser cutting machines play an important role in the manufacture of nickel-titanium electrode sheets. Next, we will introduce the application and advantages of our Men-luck laser cutting machine in t…

Laser cutting process of eye lens 2024-04-11

With the increasing demand for vision correction in modern society, glasses, as a common optical instrument for vision correction, play an indispensable role in People's Daily life. Lens processing is a delicate process that requires cutting and punching to complete the manufact…

Ultrafast femtosecond laser technology helps cardiovascular stent manufacturing 2024-04-08

With the soaring incidence of cardiovascular and cerebrovascular diseases, stent implantation has become one of the main methods of surgical treatment. Compared with traditional cutting equipment, medical laser cutting machine not only has good cutting quality, high cutting prec…

Application of laser cutting machine in mobile phone camera module manufacturing 2024-04-04

With the continuous progress of science and technology and the improvement of people's requirements for quality of life, the fields of smart wear, smart home, automotive electronics and mobile phone consumer electronics have been vigorously developed. In these fields, the camera…