What are the advantages of laser cutting in the medical devices industry?

(Click 948 )Laser cutting is a non-contact cutting process based on thermal manufacturing technology and combining focused heat and thermal energy to apply pressure to melt and spray materials at narrow paths or notches. Compared with traditional cutting methods, laser cutting has many advantages. The highly focused energy provided by laser and CNC control can accurately cut materials of different thicknesses and complex shapes. Laser cutting can realize high-precision and small tolerance manufacturing, reduce material waste, and process material diversity.

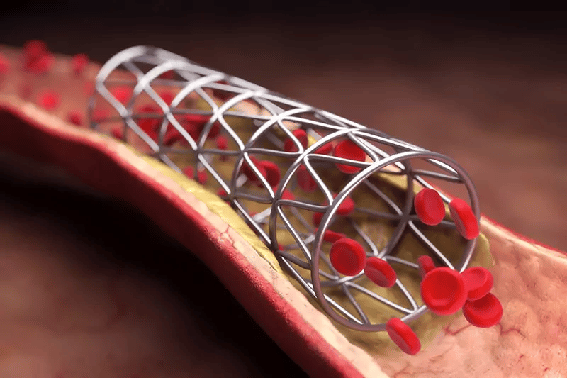

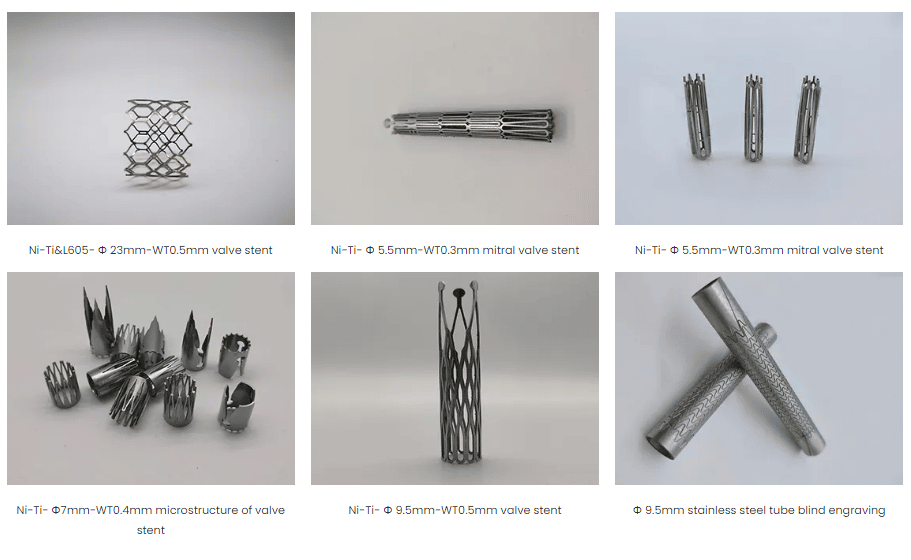

The precision laser cutting process can be widely used in various manufacturing applications. It has become a valuable asset in the medical industry, which uses a variety of materials to produce complex and Precision medical stents cutting and other medical implant products. It provide manufacturers with the following advantages in many aspects, which are the five reasons why precision laser cutting is used.

1.Excellent accuracy

The precision and edge quality of materials cut by laser are better than those of products cut by traditional methods. Laser cutting uses highly focused beam, which acts as a heat affected zone during the cutting process and will not cause large area thermal damage to adjacent surfaces. In addition, the cutting process of high-pressure gas is used to spray molten materials, remove the material slits of narrow workpieces, and process more cleanly, making the edges of complex shapes and designs more smooth. The laser cutting machine has the function of computer numerical control (CNC), and the laser cutting process can be automatically controlled by the pre designed machine program. CNC controlled laser cutting machine reduces the risk of operator error, and produces more accurate, more accurate and more strict tolerance parts.

2.Better safety

Cutting with lasers for these applications reduces the risk of accidents. Because it is a non-contact process, this means that the machine tool does not physically contact the material. In addition, no operator is required to intervene in the laser cutting process, so that the high-power beam can be safely kept inside the sealed machine. Generally, except for inspection and maintenance operations, laser cutting does not require manual intervention. Compared with traditional cutting methods, this process minimizes direct contact with the workpiece surface, thus reducing the possibility of employee accidents and injuries.

3.Greater material versatility

In addition to cutting complex geometric shapes with higher accuracy, laser cutting also allows manufacturers to cut without mechanical modification, using more materials and a wider range of thicknesses. Using the same beam with different output levels, intensities and durations, laser cutting can cut a variety of metals, making similar adjustments to the machine can accurately cut materials of various thicknesses, and integrated CNC components can achieve automation, thus providing more intuitive operations.

4.Faster delivery time

The time spent in setting up and operating the manufacturing equipment will increase the overall production cost of each piece of work. The laser cutting method can reduce the total delivery time and the total cost required for production. For laser cutting, there is no need to change and set the die between materials or material thicknesses. Compared with traditional cutting methods, the setting time of laser cutting will be greatly reduced. It involves more machine programming than loading materials. In addition, using laser to complete the same cutting can be 30 times faster than traditional cutting methods.

5.Lower material cost

By using the laser cutting method, the manufacturer can minimize the waste of materials. The beam used in the focusing laser cutting process will produce a narrow cut, thus reducing the size of the heat affected zone and the number of materials that are thermally damaged and cannot be used. When flexible materials are used, the deformation caused by mechanical machine tools also increases the amount of unavailable materials. The non-contact cutting of laser eliminates this problem. The laser cutting process can cut with higher precision and more strict tolerance, and reduce the material damage in the heat affected zone. It allows the part design to be placed more closely on the material, which reduces material waste and material cost as time goes by.

Conclusion

Laser cutting has a wide range of applications in the medical industry, including medical production equipment and equipment, cutting precision pipes and surgical applications requiring sterility and precision cutting. The resulting smaller heat affected zone reduces the amount of material wasted, thereby reducing the overall cost, and the non-contact nature reduces the risk of injury and accidents in the workplace. The programming and conversion time of the laser cutting process is faster, which can achieve greater production versatility and minimize the delivery time.

WhatsApp:

WhatsApp: Wechat

Wechat

Advantages of laser cutting nickel-titanium electrode 2024-05-06

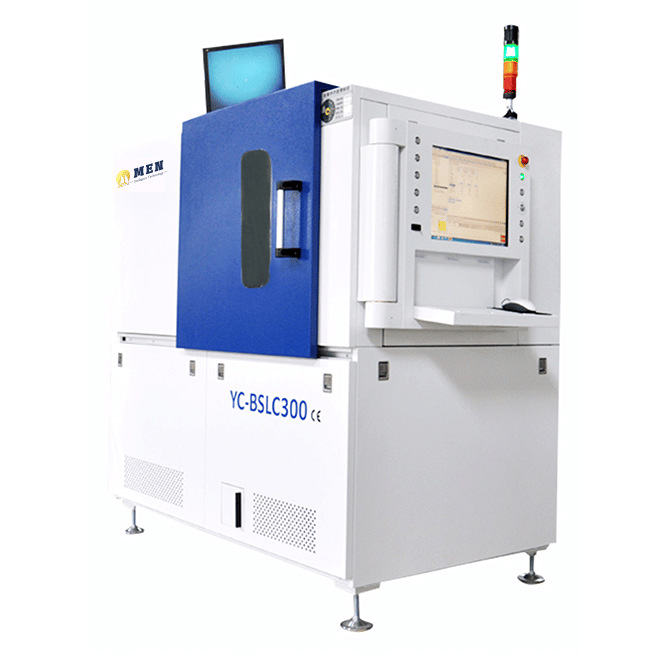

In recent years, with the continuous development of medical technology, medical laser cutting machines play an important role in the manufacture of nickel-titanium electrode sheets. Next, we will introduce the application and advantages of our Men-luck laser cutting machine in t…

Laser cutting process of eye lens 2024-04-11

With the increasing demand for vision correction in modern society, glasses, as a common optical instrument for vision correction, play an indispensable role in People's Daily life. Lens processing is a delicate process that requires cutting and punching to complete the manufact…

Ultrafast femtosecond laser technology helps cardiovascular stent manufacturing 2024-04-08

With the soaring incidence of cardiovascular and cerebrovascular diseases, stent implantation has become one of the main methods of surgical treatment. Compared with traditional cutting equipment, medical laser cutting machine not only has good cutting quality, high cutting prec…

Application of laser cutting machine in mobile phone camera module manufacturing 2024-04-04

With the continuous progress of science and technology and the improvement of people's requirements for quality of life, the fields of smart wear, smart home, automotive electronics and mobile phone consumer electronics have been vigorously developed. In these fields, the camera…