The advantages of femtosecond laser cutting machine in the processing of PTCA coronary balloon catheter

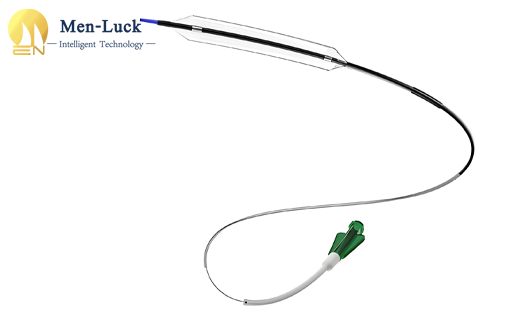

(Click 61 )Coronary artery disease is one of the leading causes of death worldwide, and percutaneous coronary intervention (PTCA) has been widely used in clinical practice as an effective treatment method. During PTCA, the coronary balloon catheter is one of the key instruments, and its manufacturing accuracy directly affects the treatment effect. Laser cutting technology, as an advanced technology in modern manufacturing, plays an important role in the processing of coronary balloon catheters.

High precision machining: Laser cutting machines can achieve micrometer level machining accuracy, ensuring accurate size and shape of balloon catheters, which is crucial for instruments that require operation in small blood vessels. Laser cutting technology can control the wall thickness error of balloon catheters at the micrometer level, greatly improving the uniformity and performance stability of the product.

Contactless processing: Laser cutting is a non-contact processing method that avoids the pollution and damage that may occur when the tool comes into contact with the material in traditional mechanical processing. This is particularly important for the cleanliness requirements of medical equipment, which can effectively reduce the risk of infection caused by instrument contamination.

Wide material adaptability: Laser cutting machines have good adaptability to various materials, including metals, polymer materials, etc. Currently, the materials for PTCA coronary balloon catheters are mostly polymer materials such as polyethylene, polyester, etc. Laser cutting technology can efficiently and accurately process them without adversely affecting the material properties.

High flexibility: The laser cutting machine can achieve cutting of complex shapes through programming, adapting to the processing needs of different types and structures of balloon catheters. In addition, laser cutting has a fast speed, which can significantly improve production efficiency and shorten product production cycles.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …