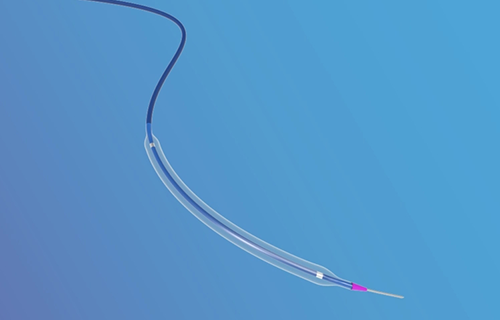

Laser cutting machine PTCA balloon catheter cutting process

(Click 412 )PTCA balloon catheter is a medical catheter used to dilate blood vessels. It enters the coronary arteries of the heart through peripheral blood vessels to dilate blood vessels. It is often used as a treatment material for coronary artery stenosis. This kind of catheter is generally made of polyethylene material and is folded and formed into a push rod to form a PTCA balloon catheter. As medical examination and surgical materials, balloon catheters have high quality requirements. Our laser cutting equipment has always been at the forefront of the industry, constantly upgraded and improved, and the technology is more advanced. The following is a detailed introduction to the catheter laser cutting machine.

The PTCA balloon catheter cutting machine can also be called a medical catheter laser drilling machine. This equipment can be used for cutting and drilling various metal and non-metallic pipes, such as large holes in balloon catheters, contrast catheters, and drainage tubes. , cutting of small holes, micro holes, single-sided holes, and double-sided holes. The PTCA balloon catheter cutting machine uses laser non-contact cutting. It focuses on high-energy laser beams, which is fast and has a small heat-affected zone. It does not affect the performance of the catheter itself. It can be equipped with an automatic loading and unloading device to achieve fully automatic cutting. The cutting surface of the balloon catheter is smooth, without burrs, the cutting slit width is small, the cutting accuracy is high (the accuracy can reach up to 5um), and the cutting efficiency is high. It is the best equipment for balloon catheter cutting on the market currently.

As a medical laser equipment R&D manufacturer, men-luck has long-term stock supply of various types of laser cutting machines, laser marking machines, laser welding machines, and laser engraving machines. Over the years, our company has continuously upgraded the equipment based on market feedback and customer needs. Currently, Our medical laser cutting machine is the most cost-effective equipment on the market. The laser cutting machine equipment can be customized according to specific product needs. Each accessory can be specially configured according to customer needs. We can also provide pre-purchase sample testing and carry out multiple Proof and test medical devices of various materials and pipe diameters. Make sure the samples are qualified before purchasing the equipment.

Quality first, customer first, always serve as the standard of men-luck service. Our company’s laser cutting equipment has sold thousands of units in China. In order to open up some blue ocean markets abroad, our company will give customers the largest price concessions and the best Service, welcome new and old customers to consult and negotiate business.

WhatsApp:

WhatsApp: Wechat

Wechat

European customers purchase laser equipments again and put them into use! 2024-12-23

A chance encounter at the train station in 2023, with enthusiastic help, allowed us to meet European customers. After in-depth communication, the final customer purchased a laser welding machine and a laser marking machine, successfully completing the first cooperation between t…

Men-Luck has came to the HANNOVER MESSE 2024-04-26

It is reported that the 2024 Hannover MESSE in Germany has more than 1,000 Chinese enterprises participating in the sea, the scale of the exhibition is second only to the host Germany, and Chinese enterprises are accelerating their integration into the global industrial chain sy…

Ultraviolet laser cutting copper foil 2024-04-18

Metal foil is a thin sheet extended by metal, and ultra-thin metal foil has a variety of applications in various industries. Titanium foil can be used in loudspeaker components and medical equipment enclosures; Materials such as tungsten and molybdenum can be used for electronic…

The 2024 Munich laser world of photonics was successfully concluded 2024-03-22

In March 2024, the three-day Munich laser world of photonics has come to a perfect end in Shanghai, which has been held in Shanghai since 2006. As an important annual event for the laser, optical and photoelectric industries in Asia, the new edition of the fair covers the photoe…