Product introduction of laser cutting machine manufacturers

(Click 1,239 )

There are many factors that affect the laser cutting machine: laser power and brand, laser cutting head, machine stability, application field, processing technology, processing control accuracy, processing format, processing materials, whether equipped with an automatic system, etc.

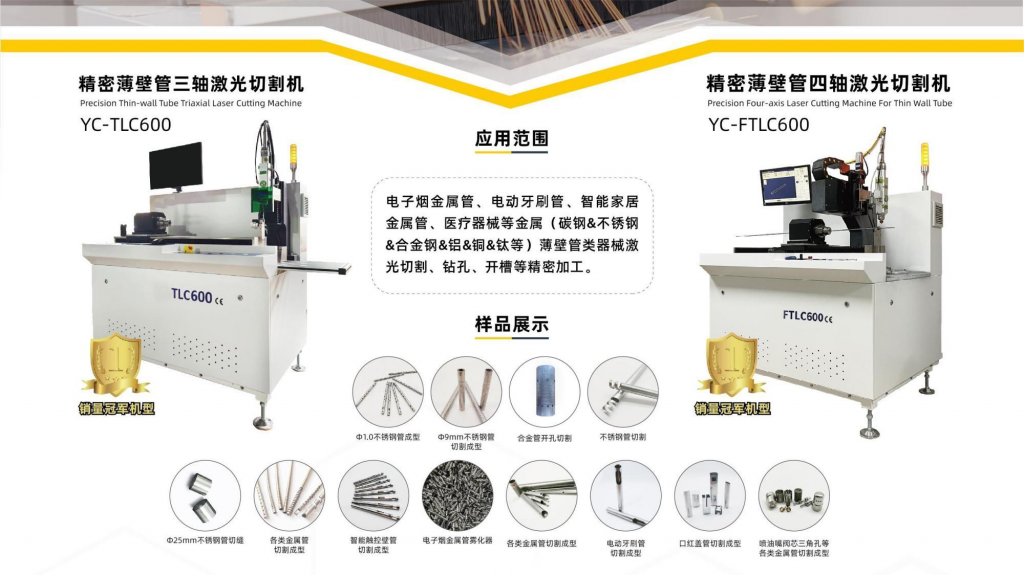

There are many subdivisions of stent laser cutting, which can be roughly divided into precision instrument processing and large-scale material processing. Large pipe processing generally has a clear demand for processing format, while laser cutting machines for precision instruments do not have the concept of processing format. They prefer processing technology, precision and efficiency.

There are many kinds of laser cutting machines on the market. Taking MEN as an example, we are a manufacturer of laser cutting machines for precision instruments. The product line is widely used in medical, electronic and other industries.

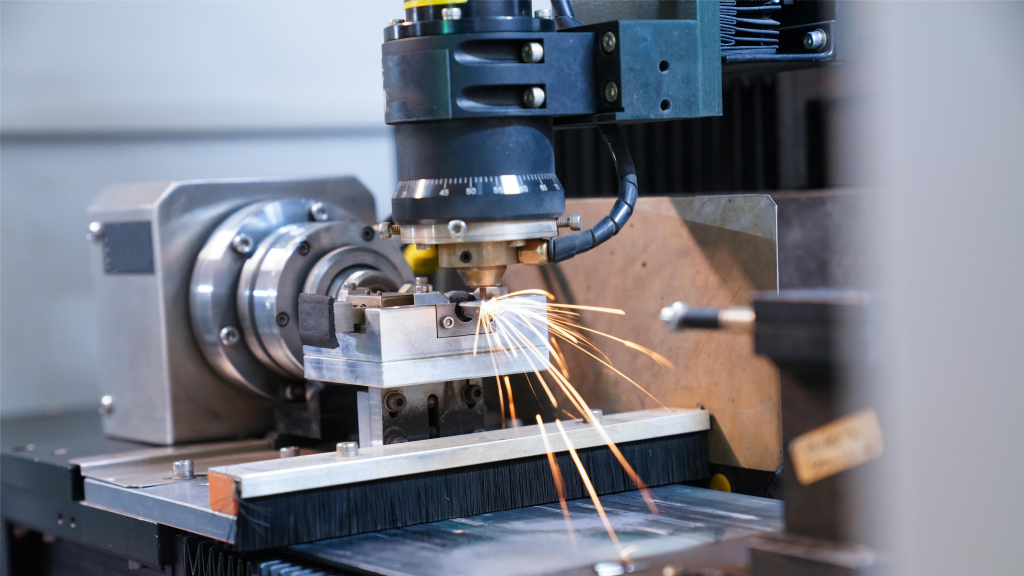

Laser cutting machine

The simple three-axis laser cutting machine TLC600 for thin-walled tubes in the field of electronic devices.

Femtosecond laser cutting machine

The ultra fast femtosecond laser cutting machine FSLC500, which is used for processing high-end medical devices such as neural interventional stents.

In addition to the better processing accuracy, the latter is also equipped with a visual monitoring system to monitor the dynamic state of laser processing in real time and support infrared&green light processing mode.

Of course, this is customized for the processing needs of medical devices. Most electronic devices do not have such a high demand.

Therefore, the price of a laser cutting machine is ultimately closely related to the processing demand. What kind of laser is equipped, ordinary fiber or femtosecond laser. And so on.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …