Precision medical devices continue to promote the development of femtosecond lasers

(Click 422 )Traditional lasers are generally mutual photothermal interaction, will produce heat affected zone, in the application of medical precision instruments, limit the minimum size of clean parts processed without melting, may lead to unacceptable functional or visual damage, and generally have to be polished, deburring and other post-processing. The peak power of the femtosecond laser is very high, and the material can be melted and evaporated instantly before the heat is transmitted to the part, making the cutting precision higher, and the relative temperature is lower, almost no hanging slag, no subsequent polishing or polishing treatment, the femtosecond laser can achieve the perfect cutting of a variety of materials.

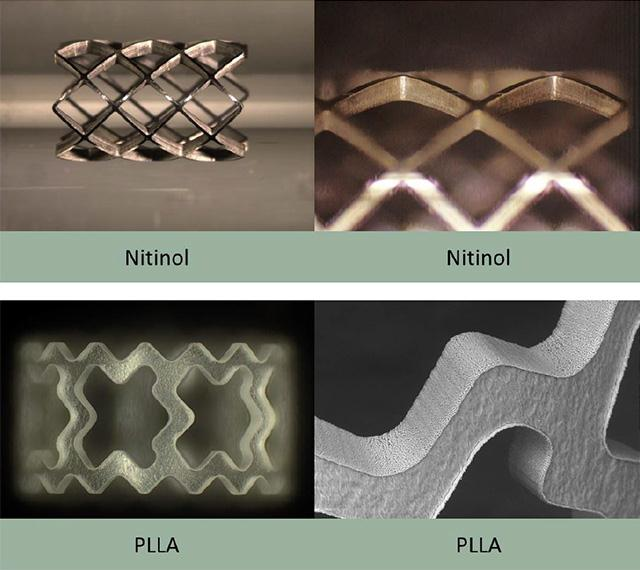

With the increasing demand of more and more people for vascular stents, peripheral stents, sea wave tubes, and minimally invasive tools, the femtosecond laser processing market share has been greatly promoted. In addition, more expensive materials and more adjustable materials are also one of the reasons for the continuous development of femtosecond lasers. Biodegradable stents are a good example, if processing with fiber lasers requires post-processing, it may reduce its capacity by about 50%, while cutting with femtosecond lasers does not require post-processing. Large mass production products such as electronic components and displays are already using this technology, constantly bringing additional market demand, which in turn pushes femtosecond laser manufacturers to develop and upgrade more advanced femtosecond laser systems.

Femtosecond lasers are already mature in terms of performance and economy or reliability. For example, the Monaco series belongs to a new generation of femtosecond lasers, whose maximum power has been continuously increased from less than 20 W to more than 60 W. The cost per watt of most femtosecond lasers has also come down. As a result, these lasers can not only help increase production, but also reduce the cost of individual parts. Earlier Monaco models have been used for several years in demanding 24/7 production environments, highlighting the higher reliability of the femtosecond laser, which in turn contributes to overall cost reduction, as well as the cost savings achieved by removing the mechanical post-processing step, which is lower for some precision cutting tasks.

Femtosecond laser can achieve streamlined automated component monitoring and processing, but also configured with matching operating software, simple and easy to use, can achieve a small batch of different equipment between the quick switch, the whole automatic operation. More suitable for thinner material cutting. Fiber lasers have a higher available power and therefore enable fast cutting and the cutting of thicker parts. So the specific choice of laser depends on the cutting material or its application scenario.

WhatsApp:

WhatsApp: Wechat

Wechat

European customers purchase laser equipments again and put them into use! 2024-12-23

A chance encounter at the train station in 2023, with enthusiastic help, allowed us to meet European customers. After in-depth communication, the final customer purchased a laser welding machine and a laser marking machine, successfully completing the first cooperation between t…

Men-Luck has came to the HANNOVER MESSE 2024-04-26

It is reported that the 2024 Hannover MESSE in Germany has more than 1,000 Chinese enterprises participating in the sea, the scale of the exhibition is second only to the host Germany, and Chinese enterprises are accelerating their integration into the global industrial chain sy…

Ultraviolet laser cutting copper foil 2024-04-18

Metal foil is a thin sheet extended by metal, and ultra-thin metal foil has a variety of applications in various industries. Titanium foil can be used in loudspeaker components and medical equipment enclosures; Materials such as tungsten and molybdenum can be used for electronic…

The 2024 Munich laser world of photonics was successfully concluded 2024-03-22

In March 2024, the three-day Munich laser world of photonics has come to a perfect end in Shanghai, which has been held in Shanghai since 2006. As an important annual event for the laser, optical and photoelectric industries in Asia, the new edition of the fair covers the photoe…