Picosecond Laser Micromachining Technology, Application Cases of Four Industries

(Click 1,195 )We are not unfamiliar with laser processing. CO2 laser, fiber laser and semiconductor laser are the mainstream lasers in industrial applications at present, in the microsecond and nanosecond level. However, in the past decade, ultrashort pulse laser fine machining technology has made rapid development in the femtosecond and picosecond level, that is, laser micro-machining we want to talk about today!

Laser micromachining

People have tried to use laser for micro-machining very early. However, due to the long pulse width and low laser intensity of the laser, the material melts and evaporates continuously. Although the laser beam can be focused into a small spot, the thermal impact on the material is still great, which limits the machining accuracy.

Only by reducing the heat effect can the processing quality be improved. When the laser pulse time of picosecond magnitude acts on the material, the processing effect will change significantly. With the sharp increase of pulse energy, the high power density is enough to peel off the outer electrons. Because the interaction time between laser and material is very short, ions have been ablated from the material surface before transferring energy to the surrounding materials, which will not bring thermal impact to the surrounding materials. Therefore, it is also called “cold working”. With the advantages of cold working, short and ultrashort pulse lasers have entered industrial production and application.

How fast is picosecond super fast?

The pulse width generated by short pulse laser is defined in picosecond and femtosecond order.

One picosecond equals 10-12 seconds, and one femtosecond equals 10-15 seconds. It may be more abstract, but we can convert it into the form of distance. For example, the speed of light is 3×108 meters per second. The time required for light to travel from the earth to the moon is about 1.3 seconds, while the distance of light movement in 1 picosecond is 0.3 mm!

What can ultrafast laser do?

The rapid development of short pulse laser technology makes it widely used in industry, and new applications will be found almost every day. At present, short pulses are mainly concentrated in the following application fields.

Drilling

In circuit board design, people began to use ceramic substrate instead of conventional plastic substrate to achieve better thermal conductivity. In order to connect electronic components, it is generally necessary to drill up to hundreds of thousands of 40100 diameters on the board μ M small hole. Therefore, it is very important to ensure that the stability of the substrate will not be affected by the heat input during the drilling process. Picosecond laser is an ideal tool for this application. Picosecond laser can complete the hole processing by impact drilling and ensure the uniformity of the hole. In addition to circuit boards, picosecond lasers can also drill high-quality holes in materials such as plastic films, semiconductors, metal films and sapphires.

Micro hole laser processing of printed circuit board (picosecond level)

Scribing, cutting

Laser pulses can be superimposed by scanning to form lines. Usually through a large number of scans, you can go deep into the interior of the ceramic until the depth of the line reaches 1 / 6 of the material thickness. The individual modules are then separated from the ceramic substrate along these scribed lines. This separation method is called scribing. Another separation method is to use ultrashort pulse laser ablation cutting, also known as ablation cutting. The laser ablates the material and removes the material until it is cut through. The advantage of this technology is that the shape and size of the processed hole have greater flexibility. All process steps can be completed by a picosecond laser.

Wire ablation (removal of coating)

Another application often seen as micromachining is the precise removal of coatings without or slight damage to the base material.

Ablation can be either a line several microns wide or a large area of several square centimeters. Since the thickness of the coating is usually much less than the width of the ablation, heat cannot be conducted on the side. Therefore, nanosecond pulse width laser can be used. The combination of high average power laser, square or rectangular conducting fiber and flat top light intensity distribution makes laser surface ablation be applied in industrial field. For example, the trumicro 7060 laser of tongkuai company is used to remove the coating on the glass of thin-film solar cell. The same laser can also be used in the automotive industry to remove the anti-corrosion coating and prepare for subsequent welding.

Surface structure

Structure can change the physical properties of the material surface. According to the lotus effect, the hydrophobic surface structure allows water to flow away from the surface. This characteristic can be realized by creating submicron structure on the surface with ultrashort pulse laser, and the structure to be created can be accurately controlled by changing laser parameters. Opposite effects, such as hydrophilic surfaces, can also be achieved, and micromachining can also create larger structures. These processes can be used in the fuel tank of the engine to manufacture some wear reducing microstructures, or structurally realize the welding with plastics on the metal surface.

Carving molding

Engraving is to create three-dimensional shapes by ablating materials. Although the size of ablation may exceed the scope of micromachining in the traditional sense, its required accuracy still makes it divided into this kind of laser application field. Picosecond laser can be used to process the edge of polycrystalline diamond cutter of milling machine. Laser is an ideal tool for machining polycrystalline diamond. Polycrystalline diamond is an extremely hard material that can make the edge of milling cutter. Engraving technology is used to process the chip grooves and teeth of milling cutter. In this case, the advantage of laser is non-contact and high machining accuracy.

Picosecond laser processing technology drill bit for processing superhard materials (picosecond level)

In short, micromachining has a very broad application prospect, and more and more daily necessities are entering our vision through laser micromachining.

Our application cases of picosecond laser cutting machine in four industries

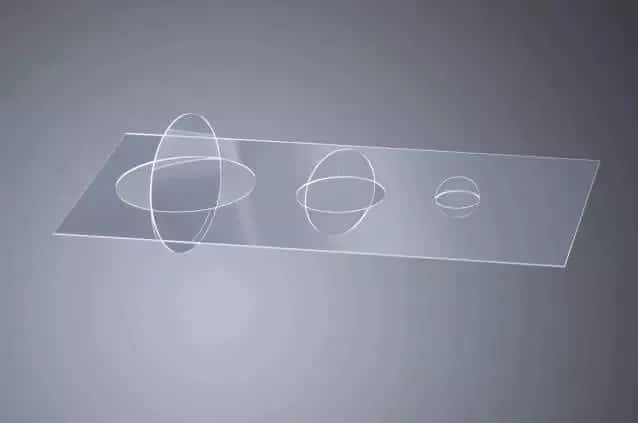

1.Application of picosecond laser cutting machine on flexible screen

The so-called flexible screen refers to a screen that can be bent and folded freely. As a new field, flexible screen is facing many problems in the processing process, which puts forward higher requirements for the processing technology. Compared with the traditional brittle material processing, OLED display screen must be processed with the highest precision in the manufacturing process because of its complex layered mechanism, so as to ensure the quality and yield. To meet such high requirements and high-precision processing conditions, laser cutting technology is the best choice at present. The laser can concentrate the light energy in the time interval from picosecond to femtosecond, and focus the light to the ultra-fine space area. The extremely high peak power and extremely short laser pulse ensure that the processing process will not affect the materials outside the space involved. Laser cutting process adopts non-contact processing method, which will not produce any mechanical stress and has no effect on the mechanical properties of the material itself. After drawing on the computer, the laser cutting machine can realize the special-shaped cutting of flexible OLED panel according to the design drawing. It has the advantages of automatic cutting, small edge collapse, high precision, diversified cutting, no deformation, fine processing and high processing efficiency. At the same time, there is no need for secondary processing such as washing, grinding and polishing, which reduces the manufacturing cost. However, using traditional machining methods to cut the flexible screen is prone to edge collapse, cracks and other problems.

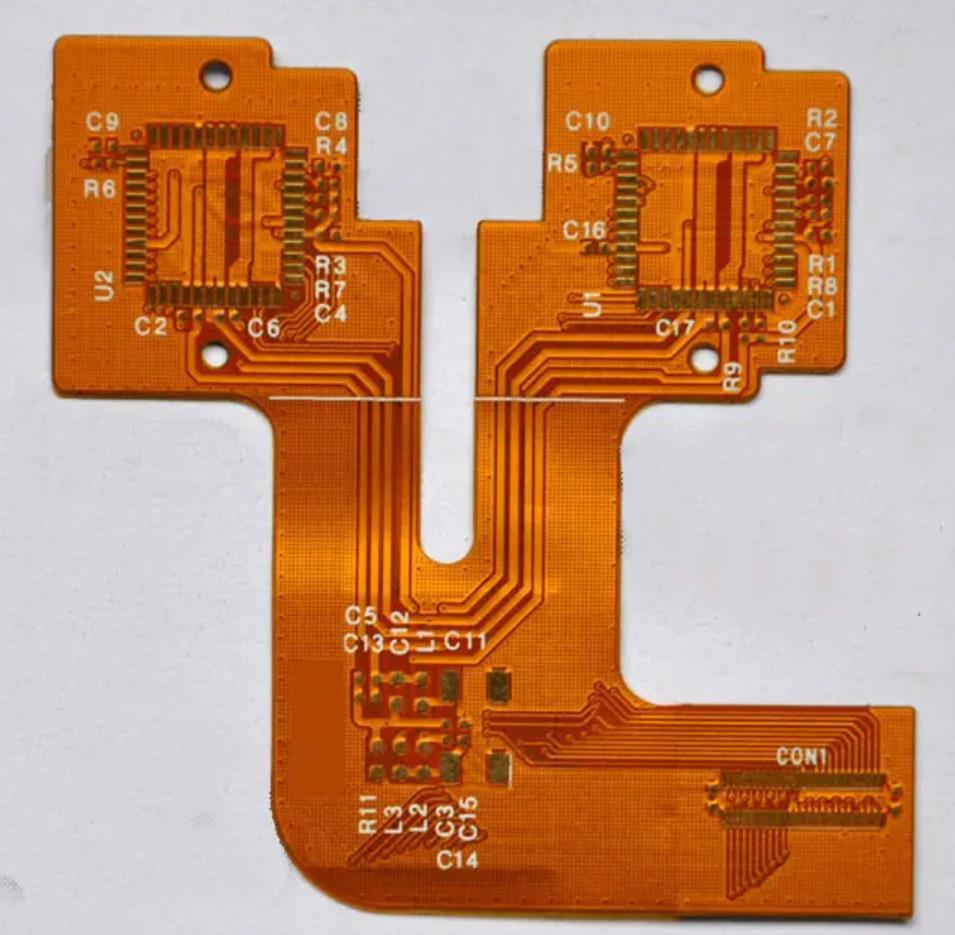

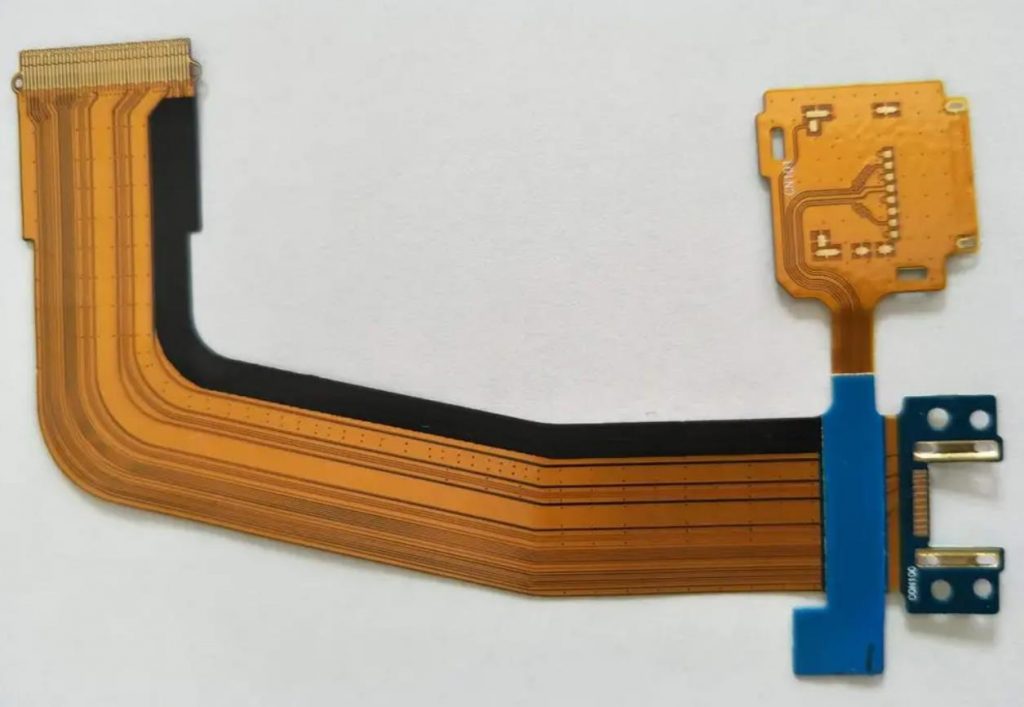

2.Advantages of picosecond laser cutting FPC copper clad laminate

Picosecond laser is widely used in the field of micro nano machining because of its short pulse width and high peak power. With the development of electronic products towards miniaturization and lightweight, the market’s requirements for FPC (flexible circuit board) integration are further improved. The traditional processing method can not meet the needs of this integration due to its own technical limitations. FPC materials generally use substrate copper foil and polyimide or polyester film circuit board. According to the characteristics of materials, comprehensive cost performance and technical factors, the best laser cutting method is UV picosecond laser cutting machine, which generally refers to UV picosecond FPC shape laser cutting machine in FPC Industry. Picosecond laser cutting machine is characterized by fast cutting speed, neat and smooth cutting edge, no burr, no glue overflow, high cutting precision, high yield and high flexibility. This is also the main characteristic of laser cutting machine replacing traditional processing methods in FPC Industry.

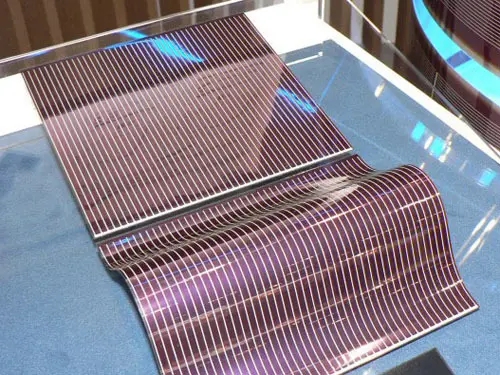

3.Picosecond laser cutting machine helps the development of thin film solar cells

Among all solar thin film cell materials, CIGS (copper indium gallium selenium) cells have the highest absorption coefficient of visible light, and the consumption of raw materials is much lower than that of traditional crystalline silicon solar cells. Compared with crystalline silicon solar cells with high efficiency and high cost and amorphous silicon solar cells with low efficiency and low cost, CIGS solar cells have multiple advantages of high efficiency, low cost and long life. CIGS solar cells are the most promising high-efficiency thin-film solar cells to reduce the cost of photovoltaic power generation, and it can make full use of China’s rich indium resources. It is a renewable energy technology suitable for China’s national conditions that truly conforms to the incentive provisions of national laws and regulations, It has broad development prospects. Picosecond laser cutting machine has high peak power because its pulse width is very short, only a few picoseconds. It is very suitable for etching and scribing solar thin film cell materials. When it interacts with the materials, the thermal influence of the etching part is very small, resulting in the effect of “cold” processing, avoiding unnecessary thermal effect, no heat affected zone, and the edge is smooth. Therefore, picosecond laser can be used for high-precision processing. The wavelength of picosecond laser ranges from infrared to ultraviolet. It can process a wide range of materials and is suitable for processing applications in many occasions. From a global perspective, the combination of solar energy technology and various fields is vibrant. From buildings, automobiles, consumer electronics to high value-added fields such as satellites, thin-film solar energy has made mankind see the infinite possibility of future energy. Picosecond laser will have a very high market prospect in the field of solar thin film cell processing because of its excellent processing ability.

4.Picosecond laser etching PI film solar cell

Solar thin film cells can be divided into two categories: hard substrate and flexible substrate. Flexible thin-film solar cells refer to thin-film solar cells made on flexible materials (such as stainless steel, polyimide, etc.). Compared with hard substrate (such as glass) thin-film solar cells, flexible thin-film solar cells have the advantages of flexibility, non fragility, light weight and so on. Let’s introduce the picosecond laser cutting machine for cutting flexible solar cell films with polyimide (PI) as substrate. The pulse width of picosecond laser is very short, only a few picoseconds, with high peak power. When it interacts with the material, the thermal effect of the laser etching part is very small, resulting in the effect of “cold” processing, avoiding unnecessary thermal effect, no heat affected zone, and the edge is smooth. Therefore, picosecond laser can be used for high-precision processing. The wavelength of picosecond laser ranges from infrared to ultraviolet. It can process a wide range of materials and is suitable for processing applications in many occasions. Picosecond laser has a very high market prospect in the field of solar thin film cell processing because of its excellent processing ability. In the processing of solar thin film cells on PI substrate, the picosecond laser etching machine has excellent laser parameters and stable performance. It not only has excellent processing effect, but also saves production cost. Online processing combined with the winding processing technology of flexible thin film cells can greatly improve the product quality and production efficiency.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of laser drilling machine in photovoltaic industry 2024-03-18

Laser drilling uses a high-energy-density laser beam to locally heat the material to a high enough temperature to evaporate, melt or vaporize it to form holes. The key to laser drilling lies in precise control of energy density, line speed and focus position to achieve precise p…

cutting machine manufacturers explain in detail the differences between ultraviolet, red light and green light sources? 2024-03-14

The most commonly used light sources for laser cutting machines are mainly red light, ultraviolet light, and green light. Each type of light source has different advantages. According to the characteristics, thickness and processing quality requirements of the processing materia…

Application and processing advantages of laser cutting machine in metal speaker mesh 2024-03-11

Metal speaker mesh is mainly used in sound-producing components of electronic equipment such as automobiles, mobile phones, and stereos. It is made of metal and has the characteristics of durability, good air permeability, etc. In the process of forming the metal speaker mesh, a…

Advantages of UV laser cutting machine for PCB processing 2024-03-07

Ultraviolet laser is a laser that generates ultraviolet beam. Since the wavelength is 355nm, ultraviolet laser is more easily absorbed by most materials, and the absorbed high-energy ultraviolet beam will directly destroy the molecular bonds of the material, thereby achieving co…