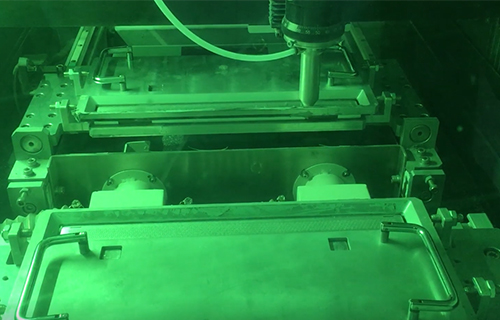

Notes on cooling operation system of high precision laser cutting machine

(Click 878 )High precision laser cutting machine to normal operation, cooling system is also an extremely important part of the configuration of the cooling system should be careful operation, learn the laser cutting machine cooling operation precautions.

In the case of water tank is not running or no water less water, high precision laser cutting machine must stop running, the general water is lower than the set value, there will be an alarm signal. Laser cutting machine as long as it is working, basically belong to high temperature and high heat, in the case of cooling system can not work normally, high temperature may cause very serious consequences.

Whether it is air-cooled or water-cooled high-precision laser cutting machine, it is necessary to clean up the dirt inside the fan and water tank, to do regular inspection and cleaning, in order to ensure the efficiency of the cutting machine.

Water cooling system is only a small part of high precision laser cutting machine, its full configuration and mobile double drive laser micromachining system, open numerical control system, computer system, and laser signal controller, laser, precision rotation axis, precision motion table, CCD vision system precision laser cutting and other important components, each part is its normal work is indispensable. For the detailed introduction of each part, you can visit our official website to understand oh!

Our main surgical instrument laser cutting machine, stent laser cutting machine, endoscope snake bone laser cutting machine and other kinds of medical equipment precision laser cutting equipment, welding equipment, marking equipment, all the equipment through 3C certification, quality assured, reasonable price, many years of research and development, production and sales experience, can provide customers with one-stop medical equipment laser microprocessing solutions, Welcome to call for advice!

WhatsApp:

WhatsApp: Wechat

Wechat

Application of laser drilling machine in photovoltaic industry 2024-03-18

Laser drilling uses a high-energy-density laser beam to locally heat the material to a high enough temperature to evaporate, melt or vaporize it to form holes. The key to laser drilling lies in precise control of energy density, line speed and focus position to achieve precise p…

cutting machine manufacturers explain in detail the differences between ultraviolet, red light and green light sources? 2024-03-14

The most commonly used light sources for laser cutting machines are mainly red light, ultraviolet light, and green light. Each type of light source has different advantages. According to the characteristics, thickness and processing quality requirements of the processing materia…

Application and processing advantages of laser cutting machine in metal speaker mesh 2024-03-11

Metal speaker mesh is mainly used in sound-producing components of electronic equipment such as automobiles, mobile phones, and stereos. It is made of metal and has the characteristics of durability, good air permeability, etc. In the process of forming the metal speaker mesh, a…

Advantages of UV laser cutting machine for PCB processing 2024-03-07

Ultraviolet laser is a laser that generates ultraviolet beam. Since the wavelength is 355nm, ultraviolet laser is more easily absorbed by most materials, and the absorbed high-energy ultraviolet beam will directly destroy the molecular bonds of the material, thereby achieving co…