Medical stents processing methods

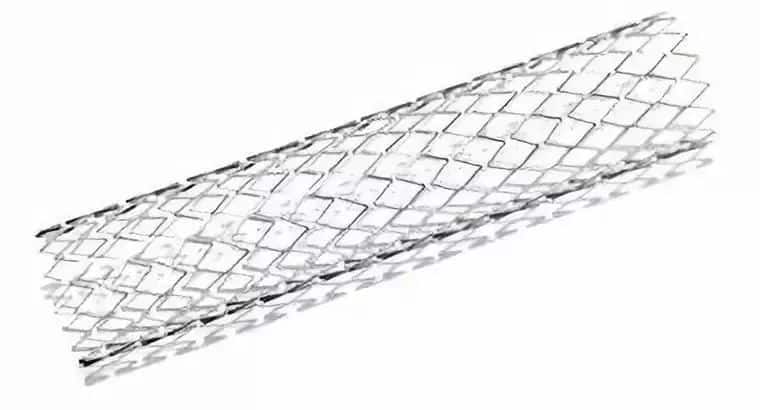

(Click 1,167 )Medical stents are used to help support and maintain the patency of various biological vessels such as blood vessels, airways, and bile ducts. These stents are made of different materials such as metals, polymers, and natural substances. And they are available in various sizes and configurations to suit different medical requirements. In this essay, we will explore the different processing methods used to manufacture laser medical device.

medical stents

- Laser Cutting: This method involves the use of laser technology to precisely cut the medical stents out of a tubular structure. Laser cutting provides high accuracy and consistency, allowing for faster production and better quality control.

- Photochemical Machining: This process involves the use of photoresist and etchant to selectively remove material from a metal sheet, leaving behind the desired stent pattern. This process offers high precision and allows for the creation of complex geometries.

- Electroforming: In this process, a metal layer is built up on a mandrel using electroplating techniques. Once the desired thickness is reached, the mandrel is removed, leaving behind the medical stents. This method offers high precision and the ability to create small features.

- Extrusion: Extrusion involves the use of a heated, viscous polymer that is forced through a die to form the desired stent shape. This process is commonly used for the production of polymer stents.

- Injection Molding: Injection molding involves the injection of molten polymer into a mold cavity, where it solidifies into the desired stent shape. This process is commonly used for the production of polymer stents and offers high throughput and repeatability.

In conclusion, there are various processing methods available for the production of medical stents. And each with its own advantages and limitations. The choice of method depends on the material used, the desired stent configuration, and the volume of production. The use of advanced manufacturing techniques such as laser cutting and electroforming has revolutionized the production of stents. Allowing for faster and more accurate production with improved quality control.

WhatsApp:

WhatsApp: Wechat

Wechat

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …

Core application of laser cutting machine in glass photoelectric encoder manufacturing 2025-06-03

As the core component of high-precision angle sensor, the processing quality of the transparent grid of glass photoelectric encoder directly affects the measurement accuracy and signal stability. Laser cutting technology breaks through the bottleneck of traditional processes wit…