Medical stents processing methods

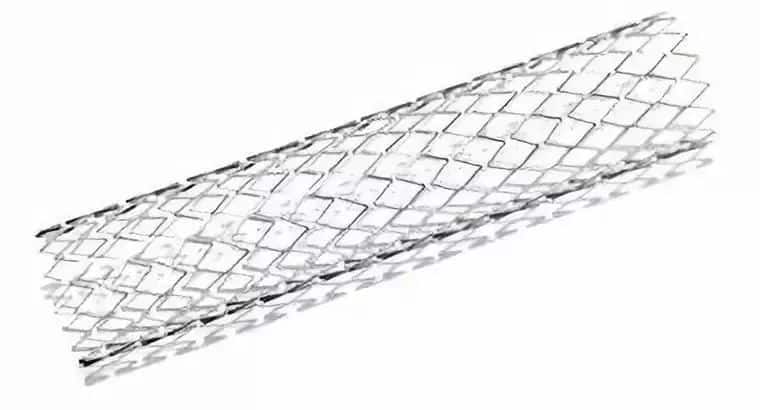

(Click 1,208 )Medical stents are used to help support and maintain the patency of various biological vessels such as blood vessels, airways, and bile ducts. These stents are made of different materials such as metals, polymers, and natural substances. And they are available in various sizes and configurations to suit different medical requirements. In this essay, we will explore the different processing methods used to manufacture laser medical device.

medical stents

- Laser Cutting: This method involves the use of laser technology to precisely cut the medical stents out of a tubular structure. Laser cutting provides high accuracy and consistency, allowing for faster production and better quality control.

- Photochemical Machining: This process involves the use of photoresist and etchant to selectively remove material from a metal sheet, leaving behind the desired stent pattern. This process offers high precision and allows for the creation of complex geometries.

- Electroforming: In this process, a metal layer is built up on a mandrel using electroplating techniques. Once the desired thickness is reached, the mandrel is removed, leaving behind the medical stents. This method offers high precision and the ability to create small features.

- Extrusion: Extrusion involves the use of a heated, viscous polymer that is forced through a die to form the desired stent shape. This process is commonly used for the production of polymer stents.

- Injection Molding: Injection molding involves the injection of molten polymer into a mold cavity, where it solidifies into the desired stent shape. This process is commonly used for the production of polymer stents and offers high throughput and repeatability.

In conclusion, there are various processing methods available for the production of medical stents. And each with its own advantages and limitations. The choice of method depends on the material used, the desired stent configuration, and the volume of production. The use of advanced manufacturing techniques such as laser cutting and electroforming has revolutionized the production of stents. Allowing for faster and more accurate production with improved quality control.

WhatsApp:

WhatsApp: Wechat

Wechat

Femtosecond laser cutting machine reshapes the limit of ultra-precision manufacturing 2025-07-08

In the field of cutting-edge manufacturing that pursues micron or even nanometer precision, traditional processing methods have gradually reached physical limits. The emergence of femtosecond laser cutting machines, with its revolutionary "cold processing" characteristics brough…

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…