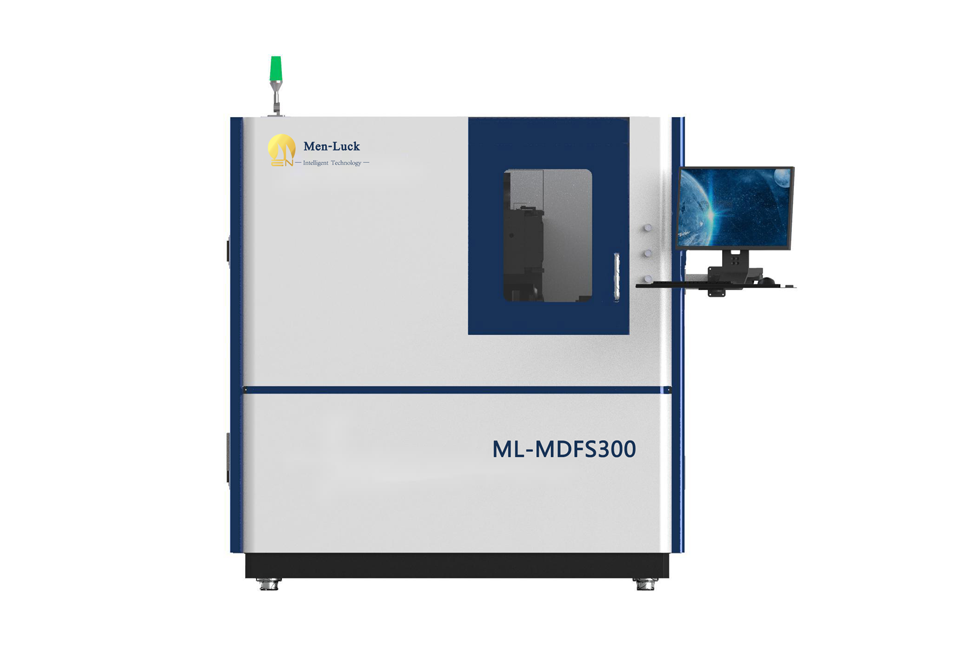

Medical femtosecond laser cutting machine for processing biochips

(Click 127 )The main material used in the production of Lab-on-a-chip or microfluidic chips is glass. Due to the microscale characteristics of chips, there are high requirements for laser microfabrication of glass during the manufacturing process.

Due to the brittleness and transparency of glass, it is difficult to perform microfabrication. If conventional tools are used for processing, they cannot meet the requirements of biochips, but medical femtosecond laser cutting machines are fully capable. When the pulse duration is less than tens of picoseconds, the interaction between the laser and the material enters a cold ablation state, and the processing quality and accuracy become very high.

Conventional microfabrication methods, such as photolithography, embossing, and soft etching, have been used to manufacture microfluidic chips. However, when it comes to implementing complex microfluidic chips with multifunctional integration, these processing methods will face significant challenges as they require more process steps and are costly.

The medical femtosecond laser cutting machine can ensure high precision and quality in processing, efficiently processing general-purpose microfluidic chips with multiple functions. The ultra short pulse width provides incredible peak power, allowing for surface and internal modification of bulk materials for marking even in transparent materials.

In addition, the use of biochip femtosecond laser cutting machines can also avoid the formation of heat affected zones, thereby reducing damage to sample structure and performance. This makes biochips have greater application prospects in fields such as molecular diagnostics and drug screening.

Men luck focuses on the research and manufacturing of laser equipment, specializing in a variety of laser cutting machines, laser welding machines, and laser marking machines, which are widely used in medical devices, electronic appliances, aerospace and other fields. We support sample sending and sampling services, and provide various laser processing solutions. Welcome to contact us if you have precision requirements for product processing. Email: info@menlaser.com

WhatsApp:

WhatsApp: Wechat

Wechat

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …