Laser cutting machine reshapes single crystal germanium precision manufacturing

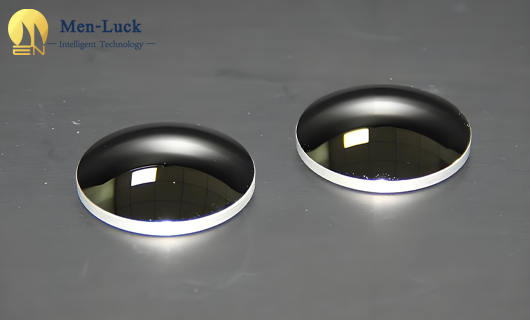

(Click 49 )In the infrared night vision device that penetrates the night sky, and behind the satellite’s lens that gazes at the earth, single crystal germanium has become the core material of high-end optics with its excellent infrared transmittance. However, the processing of this brittle crystal was once a huge challenge – the edge collapse, microcracks and lattice damage caused by traditional mechanical cutting seriously restricted the performance of the device. The emergence of laser cutting technology, like a precise “light knife”, has opened up a new era for single crystal germanium processing.

Single crystal germanium has an irreplaceable excellent transmittance to 8-14 micron infrared light, but the stress of mechanical cutting can cause edge collapse, subsurface microcracks and lattice damage, especially for thin slice processing. Laser cutting completely avoids mechanical stress with a non-contact “light blade”, and the CO2 laser cutting machine with a wavelength of 10.6 microns forms a natural energy match with the germanium material. By precisely modulating the pulse energy and action time, the laser instantly vaporizes the material at the microsecond level, controls the heat-affected zone at the micron level, and with the help of inert gas blowing, achieves a mirror-like cut surface, and the edge quality directly meets the requirements of optical assembly.

This technology not only breaks through the processing bottleneck, but also liberates the design freedom. Whether it is a special-shaped hole or a complex curved surface, the laser can accurately control it, and the motion control accuracy of ±3 microns makes the cutting trajectory as precise as a pen tip. Its value is particularly prominent in the high-end field: the infrared lens blanks provided for thermal imagers have smooth cuts to ensure high transmittance; the processed satellite sensor windows have intact lattices that can withstand extreme temperature differences in space; the undamaged edges of high-purity germanium gamma-ray detectors ensure the accuracy of signal acquisition; the flat interface of the high-power laser germanium heat dissipation substrate significantly improves the heat dissipation efficiency.

When the laser beam lightly passes over the surface of the germanium sheet, it leaves behind a geometrically precise outline, which is also a perfect protection of the material properties. This “light chisel” achieves the unity of precision and integrity in brittle crystal processing with its ultimate thermal control and contactless processing philosophy, allowing the infrared optical potential of single crystal germanium to be fully released and laying a solid foundation for human exploration of the invisible infrared world.

WhatsApp:

WhatsApp: Wechat

Wechat

Picosecond Laser Cutting Machine: A Precision Machining Solution for the Medical Industry 2025-08-05

In the medical field, picosecond laser cutting machines, with their unique advantages, are revolutionizing medical product processing and providing a powerful boost to advancements in medical technology. Picosecond laser cutting machines output energy in ultrashort pulses, with …

Laser micro-hole cutting: the key to penetrate industrial precision 2025-07-29

In the core area of precision manufacturing, a silent revolution about "micro-holes" is being led by laser cutting machines. When traditional processing is unable to cope with the microscopic scale below 0.1mm, laser, with its non-contact "blade of light", opens up a new dimensi…

Metal Laser Cutting Machine User Guide 2025-07-22

Metal laser cutting machines have revolutionized the manufacturing industry, making precise cuts in just minutes or even seconds. It is an effective way to achieve high-precision and efficient metal cutting. It can cut clean edges, but cutting different thicknesses and types of …

Femtosecond laser cutting machine reshapes the limit of ultra-precision manufacturing 2025-07-08

In the field of cutting-edge manufacturing that pursues micron or even nanometer precision, traditional processing methods have gradually reached physical limits. The emergence of femtosecond laser cutting machines, with its revolutionary "cold processing" characteristics brough…