Laser cutting machine manufactures precision flexible circuit boards

(Click 67 )Flexible circuit boards (FPCs) are core components of electronic products such as wearable devices and foldable screen mobile phones. Their micron-level lines and special-shaped contours place strict demands on processing accuracy. Laser cutting technology, with its non-contact and high-precision characteristics, breaks through the bottleneck of traditional mechanical processing and becomes a key technology for flexible electronic manufacturing, promoting continuous innovation in consumer electronics, medical sensing and other fields.

The ultraviolet laser cutting machine uses a 355nm short-wavelength light source, with a focused spot diameter of up to 15μm, and achieves non-destructive cutting of 0.05mm line width on a 25μm thick polyimide (PI) substrate. Compared with mechanical stamping processes, laser processing eliminates burrs and stress deformation, and the roughness of the cut edge is reduced to Ra < 0.8μm, ensuring the integrity of 5G high-frequency signal transmission.

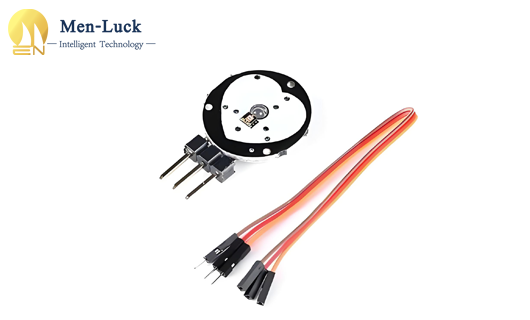

For the heart rate sensor module of smart watches, laser cutting can form a 0.2mm diameter bioelectrode window in one go, accurately exposing the conductive silver paste without damaging the underlying PET film.

Femtosecond laser technology uses the cold processing characteristics of ultrashort pulses (10^-15 seconds) to achieve local interlayer peeling in 8-layer flexible boards, selectively removing designated dielectric layers without affecting adjacent circuits. This technology overcomes the problem of multi-layer FPC rework, reducing maintenance costs by 70%, and is particularly suitable for high-reliability circuit maintenance of aerospace equipment.

Laser equipment with integrated machine vision can automatically identify FPC positioning marks, compensate for material expansion and contraction deformation, and achieve micron-level repeatable positioning accuracy. Laser processing gradually replaces traditional chemical etching processes, reducing hundreds of tons of acid waste liquid emissions each year, while supporting the precision processing of environmentally friendly materials such as PI and LCP.

From consumer electronics to implantable medical devices, laser cutting technology not only solves the manufacturing problems of flexible circuit boards, but also promotes the evolution of electronic products towards lighter, thinner and more reliable directions through process innovation. This technology is becoming the core engine for the upgrading of the flexible electronics industry, continuously expanding the boundaries of interaction between humans and smart devices.

WhatsApp:

WhatsApp: Wechat

Wechat

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …

Core application of laser cutting machine in glass photoelectric encoder manufacturing 2025-06-03

As the core component of high-precision angle sensor, the processing quality of the transparent grid of glass photoelectric encoder directly affects the measurement accuracy and signal stability. Laser cutting technology breaks through the bottleneck of traditional processes wit…