Laser drilling process of HDI circuit board resin plug hole using laser cutting machine

(Click 390 )With the rapid update of electronic product technology, the structure and installation methods of electronic chips are also constantly changing. At present, it has developed from components with plug-in pins to highly dense integrated circuit modules using spherical matrix arrangement of solder joints. PCB resin plugging is a process that has been widely used and favored in recent years, especially for high-precision multi-layer boards and products with larger thicknesses. As a professional laser cutting machine R&D and manufacturer, laser cutting and drilling are widely used. The following is a detailed introduction to the laser drilling process of HDI circuit board resin plug holes.

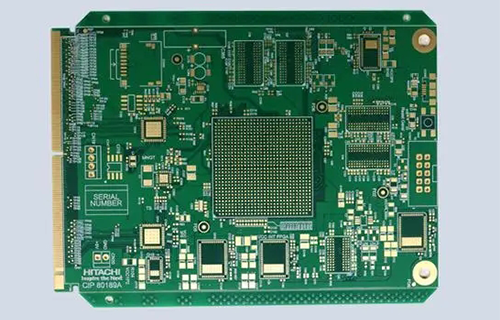

Resin plugging refers to filling the via hole and completely metallizing its surface. The thickness of the surface copper plating needs to be at least 5µm according to IPC level 2 standard, or 12µm according to level 3 standard. This technique requires the use of epoxy resin as a filler material to minimize the risk of air bubbles or filler expansion during soldering, and is typically used for in-disk holes or high-density BGA areas. After the holes in the BGA disk are plugged with resin, a layer of copper is electroplated on the surface, and then polished before patch installation. Resin plugging is mainly used for the buried holes of the inner layer HDI. The use of resin plugging can balance the contradiction between the thickness control of the lamination dielectric layer and the design of the inner layer HDI buried hole filling.

men-luck PCB laser cutting machine is a laser micro-processing equipment widely used in circuit boards, circuit board cutting and drilling. It adopts laser non-contact processing. The cutting surface is smooth, without slag, and there will be no yellowing on the surface. Black, etc., with high precision and high efficiency. In actual processing, 500-1000 holes with a diameter of 0.1-0.6mm can be drilled in one minute. Compared with traditional mechanical drilling methods, this laser drilling machine can improve production efficiency 5-10 times.

Laser cutting machine drilling has gradually replaced traditional mechanical drilling and has become the only way to reduce manufacturing costs and improve quality. At the same time, it is also the best choice for intelligent, efficient, environmentally friendly and energy-saving manufacturing. In the future, laser cutting machine drilling equipment will occupy a larger market in PCB industry manufacturing. As one of the manufacturers of laser micro-machining equipment, men-luck has many years of experience. All its equipment has passed 3C certification. The price is reasonable and the quality is reliable. You can make an appointment for proofing with incoming materials.

WhatsApp:

WhatsApp: Wechat

Wechat

European customers purchase laser equipments again and put them into use! 2024-12-23

A chance encounter at the train station in 2023, with enthusiastic help, allowed us to meet European customers. After in-depth communication, the final customer purchased a laser welding machine and a laser marking machine, successfully completing the first cooperation between t…

Men-Luck has came to the HANNOVER MESSE 2024-04-26

It is reported that the 2024 Hannover MESSE in Germany has more than 1,000 Chinese enterprises participating in the sea, the scale of the exhibition is second only to the host Germany, and Chinese enterprises are accelerating their integration into the global industrial chain sy…

Ultraviolet laser cutting copper foil 2024-04-18

Metal foil is a thin sheet extended by metal, and ultra-thin metal foil has a variety of applications in various industries. Titanium foil can be used in loudspeaker components and medical equipment enclosures; Materials such as tungsten and molybdenum can be used for electronic…

The 2024 Munich laser world of photonics was successfully concluded 2024-03-22

In March 2024, the three-day Munich laser world of photonics has come to a perfect end in Shanghai, which has been held in Shanghai since 2006. As an important annual event for the laser, optical and photoelectric industries in Asia, the new edition of the fair covers the photoe…