Four Application Directions and Future Trend Analysis of Femtosecond Laser Technology

(Click 900 )It is understatement to say that femtosecond laser technology has changed in recent years. It not only minimizes the huge progress in technology, but also improves accessibility. The complex desktop is full of components built by users and numerous discrete optical devices that need daily attention, and has given way to a single box system tailored to meet the rapidly changing world of femtosecond applications. An early example of this shift was the tunable laser for the multiphoton microscope, followed by a powerful industrial all-in-one laser to support micromachining applications from bracket cutting to OLED processing.

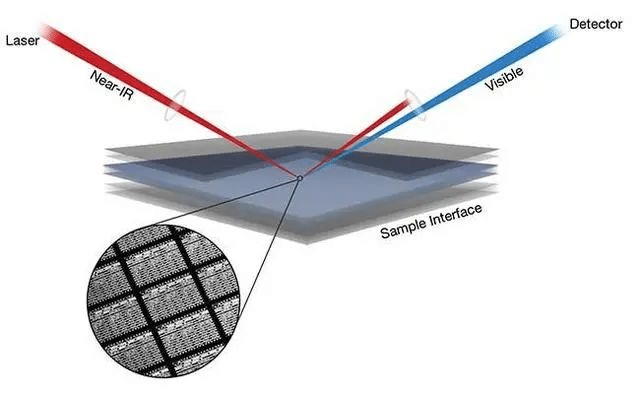

(Femtosecond laser pulses can generate a small amount of secondary harmonic light from the interface between two materials or from any non centrosymmetric material. The generated secondary harmonic light signal can nondestructive detect and image the characteristics above and below the semiconductor wafer surface, such as structural defects, film quality, and even trace metal contamination.)

Today, the latest examples of this development trend include a series of shoebox size sealed lasers with power ranges less than 5W and fixed wavelengths at key operating points, including 780, 920 and 1064 nm. These user-friendly lasers further provide application related parameters, such as short pulse width and high beam quality, pre compensation for optimizing the final pulse width, and fast modulation and control of output power.

The new generation of ultra fast lasers has been specially optimized to support user needs in the end market, such as additive manufacturing, medicine, semiconductor measurement and application research.

01 Nanofabrication

Lasers can be used in many additive manufacturing (AM) processes, including laser sintering of metals and stereo lithography of polymers. Each of these processes provides a way to create complex and unique structures without masks or molds. Additive manufacturing is particularly valuable for small-scale production applications, such as rapid prototyping of parts or personalized medical implants.

An emerging AM method is a stereo lithography technology called two-photon polymerization, which is rapidly attracting people’s interest for a variety of reasons. First, it can have higher spatial resolution than any other AM method. Secondly, it is a three-dimensional free forming process, so it is not limited by the processing limitations of laser sintering or single photon stereo lithography, in which parts must be created layer by layer from bottom to top or from top to bottom.

The advent of compact, hands-free femtosecond lasers makes two-photon polymerization and other technologies more economical and feasible in many industries and applications.

How does laser technology do this? In stereolithography, the laser beam is focused into a photosensitive resin bath. When light of appropriate wavelength (usually ultraviolet light) shines on this resin, it will break the polymer bond, and the material becomes reactive, forming solid polymer from liquid monomer chemicals.

This process allows almost any shape to be created directly from CAD files, and raw materials are not expensive. In the two-photon method, the ultrafast laser is customized to twice the normal wavelength normally absorbed by the resin. By using high numerical aperture (NA) optics, the beam is focused to the thin waist. At this waist, and only at this waist, the peak power of the ultrafast pulse is high enough to drive two-photon absorption.

This method provides unparalleled resolution for two reasons. First, using high NA optics will produce a tight micron waist. Second, since two-photon absorption depends on the square of the peak power, the transmitted laser power can be adjusted so that there is only a small central area in the laser beam. Tie the waist to cause polymerization. In this way, the process can provide submicron spatial resolution, and Hong Kong researchers reported the creation of features measuring about 100 nm. They further accelerated the process using programmable mirror arrays to create a multi beam process.

A new class of femtosecond lasers is very suitable for this application. Working at 780 nm, these lasers combine high power, short pulse width and dispersion pre compensation to provide high throughput on the focal plane. Compared with the laser with longer pulse width, these parameters result in more effective polymerization process and higher resolution. The user-friendly power control function further enhances the fine control of the process. Early applications of these new lasers include the manufacture of lab on chip products and micro structured surfaces, as well as new photonic products, such as micro patterned crystals.

02 Labelless in vivo imaging

Multiphoton excitation microscope is a widely used tool in life science research. Like two-photon photopolymerization, it depends on the spatially selective interaction with the sample only when the tightly focused beam waist uses the peak power of the femtosecond pulse.

A key trend here involves transformation research. Scientists are slowly but surely turning multiphoton technology to clinical laboratory applications, and finally to real-time applications, such as intraoperative biopsy. For obvious reasons, the target technologies are those that do not require fluorescent labeling or transgenic proteins such as green fluorescent protein to generate images. These techniques include second harmonic generation (SHG) to image collagen, where 920 nm is the appropriate wavelength; Third harmonic generation (THG) is used to image films, in which 1064 nm is a good match; And exciting endogenous fluorescence to image various biomolecules and metabolites, of which 780-800 nm is very good.

Although SHG and THG microscopes require femtosecond lasers, continuous wave lasers operating at visible or ultraviolet wavelengths can also stimulate these natural fluorophores, but at the expense of a certain imaging depth and the possibility of cell damage. Therefore, the advantages of femtosecond excitation are obvious.

Key endogenous fluorophores include reduced nicotinamide adenine dinucleotide (NADH) and flavin adenine dinucleotide (FAD), which can be used as metabolites characteristic of cancer. It is well known that cancer cells preferentially use glycolysis rather than oxidative phosphorylation to meet their energy needs. When comparing normal cells with cancer cells, there is a significant difference in the ratio of NADH to FAD. NADH is effectively excited by two-photon absorption of 700 to 800 nm wavelength, and the absorption spectrum of FAD extends to 890 nm.

Early research using these metabolites depends on two different ultrafast laser wavelengths, which is impractical for diagnosis or nursing work. Fortunately, in the past few years, researchers have proved that a single ultrafast laser operating in the 780 to 800 nm window can excite and image these two species with similar efficiency, because the stronger fluorescence of NADH can also excite the end of its spectrum at the “red”. In addition, the same researchers proved that the NADH/FAD ratio obtained in this way is a reliable marker of two different prostate cancer cell lines 2.

Similarly, the latest compact femtosecond laser operating at 780 nm is well suited for this potentially very important application. As with two-photon aggregation, other relevant laser parameters for unlabeled body imaging include excellent beam quality to maximize spatial resolution, short pulse width to minimize the average laser power required for fluorescence, and internal power control to simplify the scanning process – for example, for blanking during raster scanning.

03 Advanced wafer metering

Facts have proved that ultrafast lasers are becoming more and more important in the field of advanced wafer metrology. A mature technology, called picosecond laser acoustics (PLA), can measure layer thickness and image key alignment marks under the opaque layer. The latter capability is important in multilayer lithography.

In the PLA method, the absorption of laser pulses (i.e., pumps) generates sound waves propagating inward from the laser surface. The lower layer and structure will reflect some of the sound energy back to the surface, where it will be detected by the reflectivity change of the second laser pulse (i.e. the probe).

PLA benefits from a new generation of compact femtosecond lasers, which enable higher resolution imaging and improved overall measurement.

The latest lossless chip metrology method supported by femtosecond laser depends on the variation of the harmonic generation process used for unmarked microscopic imaging of cell membranes. The interface between two materials, or any non centrosymmetric material, will generate a small amount of secondary harmonic light in a process that is nonlinear and depends on the laser peak power. SHG optical signal can be used to image and detect various features and characteristics of the wafer surface and sub surface. These characteristics may include structural defects, film quality, and even trace metal contamination. This technology has been successfully commercialized by FemtoMetrix, which specializes in optical non visual defect measurement of surface, buried and structural irregularities.

04 Terahertz generation and detection

Terahertz radiation can provide unique spectral or imaging information in solid and liquid materials. The low optical frequency in this range is related to the vibration of nano particles, such as macro molecules such as polymers and proteins, and phonon vibration of extended structures such as crystals. Therefore, for example, terahertz studies can help to draw phase boundaries. However, the terahertz frequency range has been a neglected part of the electromagnetic spectrum for decades, because there is no simple method to generate or detect terahertz radiation.

Today, femtosecond laser pulses can be used for a variety of mechanisms to generate and detect terahertz radiation.

A method focuses a femtosecond laser pulse on a photoconductive antenna (or switch) consisting of a strip of dielectric material such as gallium arsenide (GaAs) sandwiched between two metal (e.g. gold) conductors to which a bias voltage is applied. Similar structures are also used as terahertz detectors. Another method of generating terahertz radiation is called optical rectification, which focuses the laser into a nonlinear crystal, such as gallium phosphide (GaP) or zinc telluride (ZnTe), so as to generate frequency difference between different spectral components in the terahertz pulse.

Terahertz pulses generated by femtosecond laser pulses have several advantages over terahertz pulses generated by continuous wave method. Terahertz radiation produced by ultrashort laser pulses has high intensity. It also covers a wide and continuous part of the terahertz spectrum, and its pulse characteristics support analytical techniques, such as time related spectroscopy. Therefore, pulsed terahertz radiation has found applications in imaging applications in different fields, such as medical diagnosis of cancer tissues, non-destructive evaluation of drugs, identification of explosion hazards, artistic and archaeological examinations, and national defense and security inspection tasks.

If a very short pulse is generated by a 1 to 5 kHz titanium sapphire amplifier or a nonlinear broadening ytterbium amplifier with a MHz repetition rate, the terahertz generated by optical rectification can generate a high average power pulse with a large (frequency) bandwidth.

On the contrary, due to potential optical damage and saturation effect, photoconductive antennas are limited to low excitation power. However, these antennas are the simplest and cheapest way to generate terahertz pulse radiation. Although most antennas require only 20 to 50 mW of laser power, compact femtosecond lasers emitting a single watt on an antenna tile array can achieve higher power terahertz generation in a cost-effective setup. In turn, such a setup can potentially expand the application of terahertz time-domain spectroscopy (TDS) from small-scale laboratory layout to large-scale industrial and medical imaging applications.

How does the next generation femtosecond laser fit into this terahertz image? Their short pulse width makes the spectrum range of terahertz radiation wider. Their 1 W centered high average power is useful for any terahertz generation method because they are inefficient mechanisms that require high input power.

Practical aspects of new femtosecond lasers, such as their streamlined packaging and reliability, are equally important. Some emerging applications require portable or at least portable systems to sustain the widespread adoption of these lasers. These small, cheap, wind cooling sources require minimal technical attention and can be easily integrated into a more complete system. They can be installed in any direction required.

Future thinking

Although femtosecond lasers are generally considered to be one of the most peculiar types of coherent light sources, their development and application share a mode with all other laser technologies. They have been transformed from research objects to research tools, and finally used as components in other tools and systems. Like other laser technologies, the development of femtosecond light sources has been driven by the rapid expansion of practical applications, from life sciences to industrial diagnostics to manufacturing processes.

WhatsApp:

WhatsApp: Wechat

Wechat

Advantages of laser cutting nickel-titanium electrode 2024-05-06

In recent years, with the continuous development of medical technology, medical laser cutting machines play an important role in the manufacture of nickel-titanium electrode sheets. Next, we will introduce the application and advantages of our Men-luck laser cutting machine in t…

Laser cutting process of eye lens 2024-04-11

With the increasing demand for vision correction in modern society, glasses, as a common optical instrument for vision correction, play an indispensable role in People's Daily life. Lens processing is a delicate process that requires cutting and punching to complete the manufact…

Ultrafast femtosecond laser technology helps cardiovascular stent manufacturing 2024-04-08

With the soaring incidence of cardiovascular and cerebrovascular diseases, stent implantation has become one of the main methods of surgical treatment. Compared with traditional cutting equipment, medical laser cutting machine not only has good cutting quality, high cutting prec…

Application of laser cutting machine in mobile phone camera module manufacturing 2024-04-04

With the continuous progress of science and technology and the improvement of people's requirements for quality of life, the fields of smart wear, smart home, automotive electronics and mobile phone consumer electronics have been vigorously developed. In these fields, the camera…