Femtosecond laser technology helps the rapid development of precision medical devices

(Click 461 )For many years, fiber lasers have dominated the application in the medical device manufacturing industry due to their low cost and scalable power. Laser devices such as picosecond and femtosecond have great advantages in terms of cutting quality, but their market share has been relatively small for a long time. With the continuous improvement of precision medical equipment requirements for cutting quality, coupled with the continuous development of laser technology, laser equipment is more and more widely used in the medical industry, and more and more refined. It can be used for laser cutting, laser welding, laser drilling, laser marking of various surgical instruments such as heart stents, endoscopic snake bones, and high cutting precision and good quality. Ultrafast lasers such as femtoseconds have emerged as the preferred laser in medical equipment manufacturing application scenarios, and these lasers are constantly penetrating various fields of medical treatment.

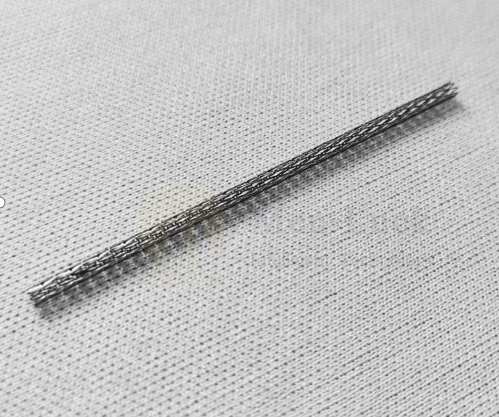

Of the medical devices manufactured using femtosecond lasers, neurological and cardiovascular stents are the most common. The femtosecond laser enables precise machining of burrless, micron-scale stent products on medical device products, which is critical to prevent immune reactions/rejection when inserted into the human body. Many medical stents are made of nickel-titanium alloy, the past use of mechanical technology to process this nickel-titanium alloy is not easy, femtosecond laser has become an effective means.

The concept of “intervention without implantation” is the most ideal stage for the innovative development of coronary interventional therapy. Heart stents have so far expanded from simple balloon stents to bare metal stents to drug-eluting stents, and biodegradable stents have been implanted.

Biodegradable scaffolds are scaffolds made of degradable polymer materials (such as polylactic acid) that can be decomposed and absorbed by the human body in a certain period of time, which is different from all previous scaffolds and is also the outstanding advantage of this kind of scaffolds. When blood vessels are remodeled, biointerpretable stents degrade directly into water and carbon dioxide in the body compared to traditional metal – and drug-coated stents. Existing research evidence shows that the efficacy of biodegradable stents is certain, which can eliminate the influence of residual bare stents on the recovery of vascular function and reduce the incidence of long-term adverse events after PCI.

With its unique advantages, biodegradable stent materials will gradually become the mainstream trend in the development of international heart stent technology. In the processing of this polymer material and other non-metallic materials, if the fiber laser processing, the material may be heated and change the chemical composition, which may produce biological toxicity. In order to reduce these thermal effects and ensure the quality of processing effects, femtosecond laser micromachining equipment is preferred. Another major point is the speed of the femtosecond laser, which can greatly reduce the contact time between the beam and the workpiece, and minimize the heat affected zone on the workpiece, thereby reducing the adverse effects caused by excessive heating. For some medical devices, including stents, this is also critical to improving the biocompatibility of implant materials.

Femtosecond laser can process products within the accuracy range of 5um, so the general medical implantable vascular stent, coronary stent and other large stent, small stent using femtosecond laser cutting machine can achieve cutting accuracy and high quality requirements of the cutting surface, femtosecond laser can also reduce the post-processing needs of cutting stent to a minimum.Strength manufacturers, rest assured to buy.

WhatsApp:

WhatsApp: Wechat

Wechat

European customers purchase laser equipments again and put them into use! 2024-12-23

A chance encounter at the train station in 2023, with enthusiastic help, allowed us to meet European customers. After in-depth communication, the final customer purchased a laser welding machine and a laser marking machine, successfully completing the first cooperation between t…

Men-Luck has came to the HANNOVER MESSE 2024-04-26

It is reported that the 2024 Hannover MESSE in Germany has more than 1,000 Chinese enterprises participating in the sea, the scale of the exhibition is second only to the host Germany, and Chinese enterprises are accelerating their integration into the global industrial chain sy…

Ultraviolet laser cutting copper foil 2024-04-18

Metal foil is a thin sheet extended by metal, and ultra-thin metal foil has a variety of applications in various industries. Titanium foil can be used in loudspeaker components and medical equipment enclosures; Materials such as tungsten and molybdenum can be used for electronic…

The 2024 Munich laser world of photonics was successfully concluded 2024-03-22

In March 2024, the three-day Munich laser world of photonics has come to a perfect end in Shanghai, which has been held in Shanghai since 2006. As an important annual event for the laser, optical and photoelectric industries in Asia, the new edition of the fair covers the photoe…