Coronary stent laser cutting advantages

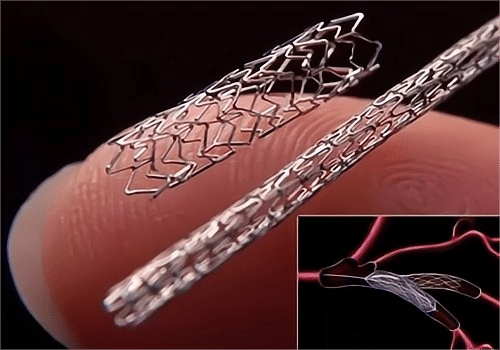

(Click 1,140 )Coronary stent laser cutting is a manufacturing process. It involves the use of laser technology to precisely cut and shape medical stents. This technique offers several advantages over traditional methods of stent production. Especially for manual cutting or the use of other cutting tools. In this essay, we will explore the advantages.

Advantages of coronary stent laser cutting

High precision of laser cutting.

One of the primary advantages is its precision. Laser cutting allows for extremely accurate cuts with a high level of consistency. To make sure each stent is uniform in shape and size. This precision is essential in medical device manufacturing, where the tiniest of variations can have a significant impact on performance and safety.

High efficiency of laser cutting.

Another advantage is its efficiency. Laser cutting machines are highly automated, and the entire process can be completed quickly and with minimal human intervention. This results in faster production times, lower labor costs, and increased output. In addition, laser cutting machines can process a wide range of materials, including stainless steel, nitinol, and platinum, making it a versatile solution for stent manufacturing.

High quality of laser cutting.

Coronary stent laser cutting also offers superior quality control. The process is highly repeatable and consistent, allowing manufacturers to produce stents that meet stringent quality standards. This is essential in the medical industry, where patient safety is a top priority. By using laser cutting, manufacturers can produce stents that are highly reliable, with consistent performance across a large number of units.

In addition to its precision, efficiency, and quality control benefits, coronary stent laser cutting also offers significant cost savings. While the initial investment in a laser cutting machine may be higher than that of traditional cutting tools, the long-term cost savings are substantial. This is due to the reduced labor costs, faster production times, and increased output that laser cutting provides. As a result, manufacturers can produce more stents at a lower cost, making it an attractive option for companies looking to improve their bottom line.

In conclusion, coronary stent laser cutting offers significant advantages over traditional cutting methods. Its precision, efficiency, quality control, and cost savings benefits make it an excellent choice for medical device manufacturers looking to produce high-quality stents at a lower cost. As the technology continues to evolve, we can expect to see even more benefits emerge in the years to come.

WhatsApp:

WhatsApp: Wechat

Wechat

Advantages of laser cutting nickel-titanium electrode 2024-05-06

In recent years, with the continuous development of medical technology, medical laser cutting machines play an important role in the manufacture of nickel-titanium electrode sheets. Next, we will introduce the application and advantages of our Men-luck laser cutting machine in t…

Laser cutting process of eye lens 2024-04-11

With the increasing demand for vision correction in modern society, glasses, as a common optical instrument for vision correction, play an indispensable role in People's Daily life. Lens processing is a delicate process that requires cutting and punching to complete the manufact…

Ultrafast femtosecond laser technology helps cardiovascular stent manufacturing 2024-04-08

With the soaring incidence of cardiovascular and cerebrovascular diseases, stent implantation has become one of the main methods of surgical treatment. Compared with traditional cutting equipment, medical laser cutting machine not only has good cutting quality, high cutting prec…

Application of laser cutting machine in mobile phone camera module manufacturing 2024-04-04

With the continuous progress of science and technology and the improvement of people's requirements for quality of life, the fields of smart wear, smart home, automotive electronics and mobile phone consumer electronics have been vigorously developed. In these fields, the camera…