Application of laser cutting machine in precision alloy instrument processing

(Click 65 )Precision alloys (such as titanium alloy, nickel-based high-temperature alloy, medical stainless steel, etc.) are widely used in aerospace, medical equipment and precision instruments due to their high strength, corrosion resistance and biocompatibility. Laser cutting technology breaks through the limitations of traditional processes for processing complex alloy instruments through non-contact processing and intelligent energy regulation, and becomes the core support of high-end manufacturing.

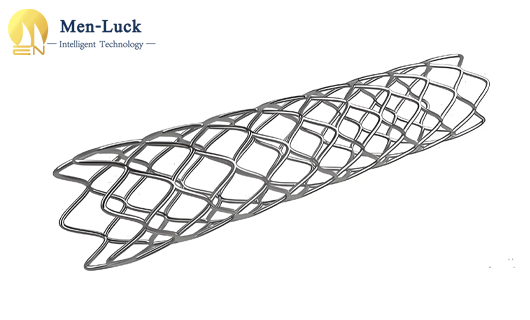

Precision alloy instruments have strict requirements on dimensional tolerances, and traditional wire cutting or stamping can easily cause material deformation or thermal damage. Fiber laser cutting machines achieve micron-level precision cutting through a spot size below 100μm, with a heat-affected zone of less than 50μm and no burrs on the cut. For example, when the MenLuck equipment processes cardiovascular stents, it can cut a hollow grid with a width of only 30μm on a 0.1mm thick nickel-titanium alloy tube to ensure the flexibility and functionality of the instrument.

Aircraft engine blades, micro sensors and other components often require processing of curved surfaces, special-shaped holes and microchannels. Laser cutting uses five-axis linkage technology to achieve multi-angle precision processing in three-dimensional space. The “3D laser cutting system” launched by the company can complete the processing of 0.3mm diameter group holes on high-temperature alloy turbine disks. Compared with the EDM process, the efficiency is greatly improved and no subsequent polishing is required.

From ultra-high hardness tungsten alloys to highly reflective copper alloys, laser cutting achieves stable processing through wavelength adjustment and pulse control. Not only can it improve material utilization, mold-free processing also greatly shortens the development cycle of medical devices and accelerates product iteration.

MenLuck focuses on the research and development and manufacturing of industrial-grade laser equipment, providing global customers with integrated intelligent equipment for laser cutting, marking, and welding. Its services cover 3C electronics, medical devices, aerospace, hardware accessories and other manufacturing fields. Companies that have demand for laser equipment are welcome to contact us: E-mail: info@menlaser.com

WhatsApp:

WhatsApp: Wechat

Wechat

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …

Core application of laser cutting machine in glass photoelectric encoder manufacturing 2025-06-03

As the core component of high-precision angle sensor, the processing quality of the transparent grid of glass photoelectric encoder directly affects the measurement accuracy and signal stability. Laser cutting technology breaks through the bottleneck of traditional processes wit…