Application of femtosecond laser processing in medical equipment industry

(Click 1,240 )Millisecond (MS) fiber lasers have been successfully used in medical equipment applications for many years, such as the cutting of injection tubes and stents. Although precise and fast, the disadvantage of this processing method is that a series of post-processing is always required after the parts are cut, which significantly increases the cost of the parts and increases the risk of damage to these delicate mechanical parts.

In recent years, the technology of ultrashort femtosecond (FS) laser has been developed. The laser pulses generated by this laser will not leave thermal fingerprints on the components. These femtosecond lasers provide laser pulses shorter than 400fs and excellent beam quality, and have sufficient peak power to realize high-quality cold ablation cutting process without using melt jet process. The cutting process thus performed requires only a minimum amount of post-processing, and a finer beam can be processed into very delicate details.

This process is particularly effective in the production of medical devices, such as catheters, heart valves and medical stents, and can be used for glass cutting and marking applications, as well as 3D structure manufacturing of dental implant ceramic materials. However, perhaps the most potential application lies in a new type of bioabsorbable materials, that is, polymer materials that can be safely retained in the body and subsequently absorbed within a controlled length of time. These materials are currently under development and will be used to replace traditional polymers or metal parts.

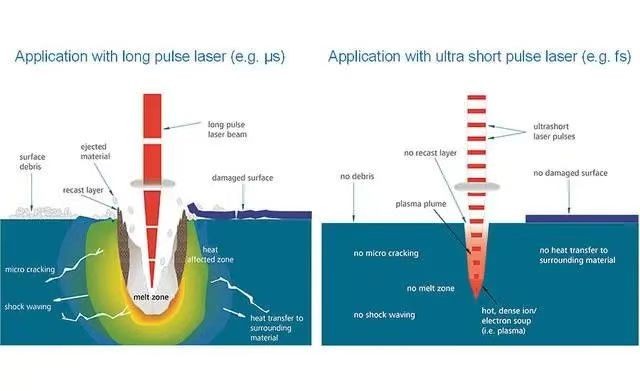

Fig. 1: this figure compares the processing results of millisecond laser and femtosecond laser

1.Basic characteristics of femtosecond laser

Femtosecond optical pulses belong to ultra short pulses (USP). 1FS = 10-15s, as the calibration point, one 300fs pulse is equal to only 90 μ M U.M. Unlike the thermal processing process of nanosecond (NS) pulses, USP has many advantages: no thermal shock, no shock wave, no micro crack, no melting effect, no surface damage, no debris, no material injection, no recasting layer.

Femtosecond laser technology is not a new technology. It has been widely used in scientific research institutions and research centers for more than 30 years. However, the commercially applicable femtosecond laser technology needs to be able to work all day in an industrial environment, and this technology has only appeared for about seven years. Femtosecond lasers have recently been used for wafer slicing and etching P1, P2 and P3 level solar power panels, or for manufacturing trenches for power supply electrodes on battery panels. Now, such lasers have set off a wave of new processing capabilities, and many medical devices will become excellent candidates for this processing method, especially considering the high cost of this process in processing parts.

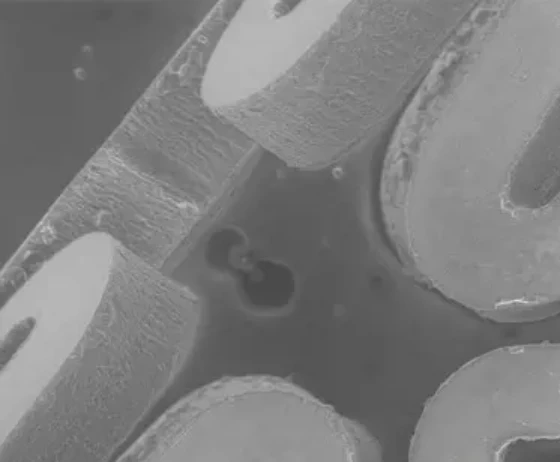

Fig. 2:the above comparative photos show the holes drilled with a 355nm nanosecond (NS) laser (left) ,and a 1030nm femtosecond disc laser (right)

Using femtosecond laser to process metal and plastic materials can achieve excellent edge quality, which makes this laser can be applied to heart, brain and eye stents (nickel titanium alloy and cobalt chromium alloy), catheters, heart valves and polymer tubes. This almost cold cutting process means that very fine external feature dimensions can be cut on the lightest and thinnest materials while maintaining mechanical and material integrity. Even for processing nitinol tubes with the smallest diameter, there is no need for water cooling in the tubes.

2.The edges show the same finish as the material surface

Take the general-purpose coronary stent as an example, which is the first device manufactured with fiber laser. First, this part must be machined, then polished with mechanical tools, or cleaned internally, and finally deburred. Subsequently, a chemical etching process must be performed to clean the periphery of the edge, and then an electrolytic polishing process must be performed. These steps not only take a long time, but also may cause the parts to be fragile and deformed, and can produce microcracks. The yield rate is in the range of 70%, which means that a considerable share of the final products become losses. In contrast, femtosecond lasers belong to dry processing and do not introduce water or heat into the components. The number of processes was greatly reduced, and the parts were processed, followed by an electrochemical process to round the edges. The integrity of components has been improved, and many time-consuming processes have been eliminated, and the yield rate can be close to 95%.

Femtosecond lasers can also process medical products using new bioabsorbable polymers. This polymer can be safely implanted in the body and controlled for a length of time, followed by absorption, and does not cause harmful or adverse interactions. Bioabsorbable polymers (also known as aspirants) provide alternative materials for traditional polymers or metal parts, and are designed to meet the precise degradation rate requirements and other specifications.

The bioabsorbable material can be processed into any shape that can be used for scaffolds. However, this material must be processed correctly and no heat must be introduced. If the above requirements cannot be met, crystallization will occur in the material, which will degrade the structure of the material and affect its service life and the ability to slow release the drug at the correct speed. Moreover, since bioabsorbable materials will dissolve, they cannot be cleaned like most plastics, and they cannot contact any liquid solvents. This is also the reason why femtosecond laser technology is more suitable for this material.

Fig. 3:shows an example of a femtosecond laser cutting a biodegradable stent.

WhatsApp:

WhatsApp: Wechat

Wechat

Advantages of laser cutting nickel-titanium electrode 2024-05-06

In recent years, with the continuous development of medical technology, medical laser cutting machines play an important role in the manufacture of nickel-titanium electrode sheets. Next, we will introduce the application and advantages of our Men-luck laser cutting machine in t…

Laser cutting process of eye lens 2024-04-11

With the increasing demand for vision correction in modern society, glasses, as a common optical instrument for vision correction, play an indispensable role in People's Daily life. Lens processing is a delicate process that requires cutting and punching to complete the manufact…

Ultrafast femtosecond laser technology helps cardiovascular stent manufacturing 2024-04-08

With the soaring incidence of cardiovascular and cerebrovascular diseases, stent implantation has become one of the main methods of surgical treatment. Compared with traditional cutting equipment, medical laser cutting machine not only has good cutting quality, high cutting prec…

Application of laser cutting machine in mobile phone camera module manufacturing 2024-04-04

With the continuous progress of science and technology and the improvement of people's requirements for quality of life, the fields of smart wear, smart home, automotive electronics and mobile phone consumer electronics have been vigorously developed. In these fields, the camera…