Advantages of ultrafast pulse laser cutting machine

(Click 46 )When the laser works with a pulse time of nanoseconds, it can achieve very high pulse energy, peak power and average power, opening up a wider application space for micro-machining applications such as thin-film cutting, connection and surface treatment, so as to be used for cleaning, ablation and surface functionalization.

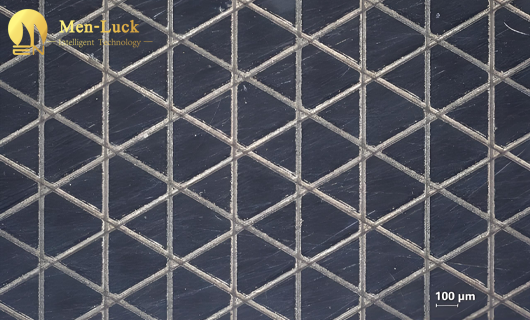

When the laser acts on the material with a pulse time of picoseconds, the processing effect will change significantly. As the pulse energy rises sharply, the high power density is enough to strip the outer electrons. Because the laser interacts with the material for a very short time, the ions are ablated from the surface of the material before transferring energy to the surrounding material, and will not cause thermal effects on the surrounding materials, so it is also called “cold processing”.

Ultra-short pulse processing energy is injected into a very small action area very quickly, and the instantaneous high energy density deposition changes the absorption and movement mode of electrons, avoiding the effects of laser linear absorption, energy transfer and diffusion, and fundamentally changing the mechanism of laser-matter interaction.

Like general laser processing, it is a non-contact processing. The use of ultrashort pulse lasers in microprocessing has unique advantages, including enhanced dimensional accuracy and tighter tolerances, reduced damage and removal of subsequent processing steps.

The laser uses a thin disk or fiber architecture to achieve high power output and a pulse duration of femtoseconds. It has fewer subsequent processes, good controllability, easy integration, and high processing efficiency. It plays an increasingly important role in improving product quality, labor productivity, automation, reducing material consumption, and improving environmental quality.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …