Advantages of ultrafast pulse laser cutting machine

(Click 64 )When the laser works with a pulse time of nanoseconds, it can achieve very high pulse energy, peak power and average power, opening up a wider application space for micro-machining applications such as thin-film cutting, connection and surface treatment, so as to be used for cleaning, ablation and surface functionalization.

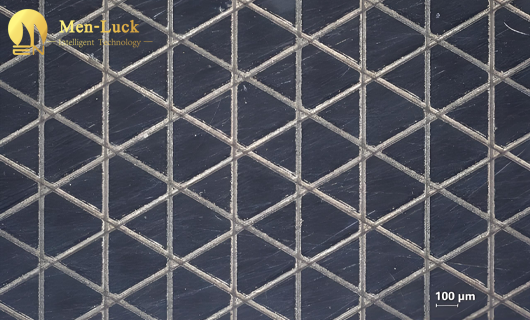

When the laser acts on the material with a pulse time of picoseconds, the processing effect will change significantly. As the pulse energy rises sharply, the high power density is enough to strip the outer electrons. Because the laser interacts with the material for a very short time, the ions are ablated from the surface of the material before transferring energy to the surrounding material, and will not cause thermal effects on the surrounding materials, so it is also called “cold processing”.

Ultra-short pulse processing energy is injected into a very small action area very quickly, and the instantaneous high energy density deposition changes the absorption and movement mode of electrons, avoiding the effects of laser linear absorption, energy transfer and diffusion, and fundamentally changing the mechanism of laser-matter interaction.

Like general laser processing, it is a non-contact processing. The use of ultrashort pulse lasers in microprocessing has unique advantages, including enhanced dimensional accuracy and tighter tolerances, reduced damage and removal of subsequent processing steps.

The laser uses a thin disk or fiber architecture to achieve high power output and a pulse duration of femtoseconds. It has fewer subsequent processes, good controllability, easy integration, and high processing efficiency. It plays an increasingly important role in improving product quality, labor productivity, automation, reducing material consumption, and improving environmental quality.

WhatsApp:

WhatsApp: Wechat

Wechat

Femtosecond laser cutting machine reshapes the limit of ultra-precision manufacturing 2025-07-08

In the field of cutting-edge manufacturing that pursues micron or even nanometer precision, traditional processing methods have gradually reached physical limits. The emergence of femtosecond laser cutting machines, with its revolutionary "cold processing" characteristics brough…

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…