The Birth of Laser and Optical Fiber Ⅱ

(Click 1,024 )Menlaser is a professional laser cutting system solution service provider.We provide Medical laser tube cutting,laser tube cutting for medical,medical precision laser tube cutting,medical tube cutting machine,medical device laser tube cutting,medical precision laser tube cutting,medical tube laser cutting, Let’s introduce the knowledge of Laser and Optical Fiber.

No. 4 Laser and optical communication

Broadcast and long-distance telephone grew steadily after the Second World War. The communication industry hopes to transmit signals on a higher carrier frequency and provide wider bandwidth.

In the 1950s, Bell Systems, a regulated monopoly that provides telephone services in the United States, began to develop a system that transmits at a frequency of 50 GHz. The system must be buried in a hollow metal waveguide, because the atmosphere will absorb signals at these frequencies.

When consulting Bell Labs, Townes asked them to be interested in the greater potential transmission capacity of the optical frequency of the next-generation telephone system. Bell began to study optical waveguides after early tests showed that the transmission of laser beams in the atmosphere was unstable. Rudolf Kompfner, head of transmission research at Bell, first thought of using hollow waveguides, just like those used in 50 GHz systems. He also asked one of his employees to find out the clearest optical fiber loss on the market; The answer is about 1000 dB/km, which is obviously not enough for communication, so Bell pursues hollow optical waveguide.

Corning Glass Factory in the United States has developed ultra-pure quartz glass that can withstand high temperature baking. When Robert Maurer of Corning heard about Kao Kun’s research on ultra-transparent glass, he and his colleague Frank Zimar started a small project: transforming heat-resistant glass to achieve low attenuation. When the project went well, he hired young scientists Donald Keck and Peter Schultz to spend more time on the project. In 1970, they reported a kind of optical fiber with a loss of 17 dB/km on the red He-Ne laser line.

Kao Kun, a Chinese-born physicist, measured the transparency of fused quartz at the British standard telecommunications laboratory

This is a game-changing breakthrough, but the first low-loss fiber is too fragile for practical use. In 1972, Corning reported that the loss at 850 nm was reduced to 4 dB/km, and the addition of germanium in the core made the fiber more durable. In 1976, Masaharu Horiguchi of NTT Ibaraki Laboratory in Japan and Hiroshi Osanai of Fujikura Cable in Japan opened the transmission window at the zero dispersion wavelength of 1.3 μ m and the minimum fiber loss of 1.55 μ m. Their loss is less than 0.5 dB/km at both wavelengths, which shifts the work of long-distance optical fiber to these frequency bands. By then, Bell had completed the field test and quietly abandoned the 50 GHz system.

No. 5 Another breakthrough: diode laser

If there is no breakthrough in laser performance, the breakthrough in fiber loss will not be meaningful. The early gas and solid lasers were bulky and inefficient. Therefore, the invention of diode lasers in 1962 greatly promoted the development of laser communication. After the researchers at the Lincoln Laboratory of the Massachusetts Institute of Technology (MIT) reported the light emission jump of GaAs diode, it appeared very quickly, so that a speaker thought they violated the second law of thermodynamics.

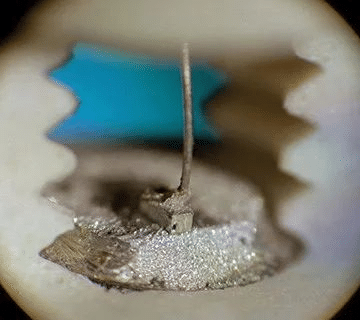

A close-up of the early diode laser in the Lincoln Laboratory of MIT

The MIT team did not do this, but it showed that GaAs is a very good candidate material for diode lasers. Within a few weeks, the team and three other teams joined the resonator and made the first batch of diode lasers. Diode lasers, made of semiconductors, are the most popular technology in the field of electronics, and begin to appear very attractive in laser communication.

However, the first batch of diode lasers can only emit short pulses at low temperatures. After more than ten years of progress, reliable room temperature operation has been achieved. The first step was to win the Nobel Prize for the semiconductor heterostructure invented by Zhores I. Alferov and Herbert Kroemer. However, it was not until 1970 that Alferov’s team and an independent team of Bell Laboratories demonstrated the continuous wave operation of diode lasers at room temperature. It took another seven years before Bell Labs produced a GaAs diode laser that could work at room temperature for 100 years.

Ironically, at the same time, the opening of the long-wavelength fiber window transferred the ideal wavelength from the 850 nm band of GaAs to the 1310 nm band. In this band, the dispersion of quartz fiber is zero and the attenuation is low. Fortunately, for compound semiconductors, changing the mixture of elements in the diode can change its emission line. In this case, adding indium and phosphorus to gallium arsenide can increase its wavelength, so it will not be long before an InGaAsP laser that can be emitted at 1310 nm can be produced, and later it can also be emitted at 1550 nm. Although there are some small compromises, the process developed for GaAs is effective for most long wavelengths of InGaAsP.

No. 6 followed by technical breakthrough: single-mode fiber

Kao Kun’s initial proposal required the use of single-mode fiber, because according to his experience in 50 GHz embedded millimeter waveguides, multimode transmission may cause serious noise problems. However, the small core required for single-mode transmission makes it difficult to connect two sections of optical fiber without losing most of the light. The core diameter of an 850 nm step-index fiber must be less than about 5 microns before it can be used for single-mode operation, which leads to loss of optical coupling.

Transferring the transport to 1310 nm changed the rules. At this wavelength, the diameter of the single mold core is about 9 microns, and the tolerance of mechanical connection is also improved. But the biggest advantage is to eliminate modal dispersion and reduce attenuation, which limits the data transmission rate and transmission distance. In the early 1980s, single-mode systems jumped from 45 Mbit/s and 10 kilometers to 400 Mbit/s and 30 kilometers; By the 1990s, the maximum data rate was 2.5 Gbit/s, and the wave of technological breakthroughs began to take shape.

No.7 The great foundation oftransmission system: optical fiber amplifier and WDM

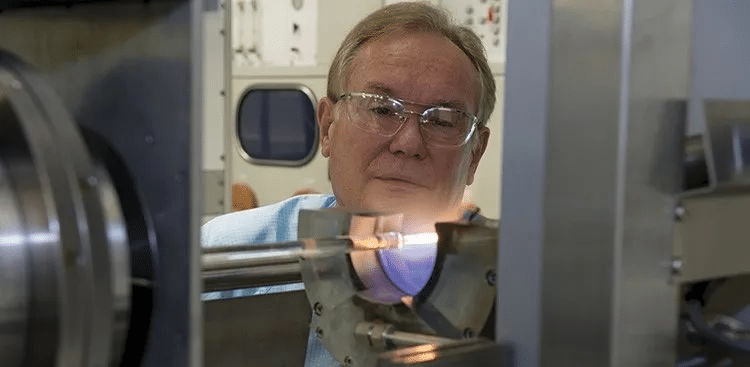

The long-distance optical fiber transmission in the 1980s relied on electro-optical repeaters spaced 30 to 50 kilometers apart. Each repeater converts the input optical signal into electronic form for electronic amplification, and then uses the electronic output to drive the laser to send the signal to the next span. Quartz optical fiber is close to its possible minimum attenuation, and no better fiber material can be found. Semiconductor optical amplifiers (diode lasers without resonators) seem to be the logical next step, but their signal quality has proved to be insufficient.

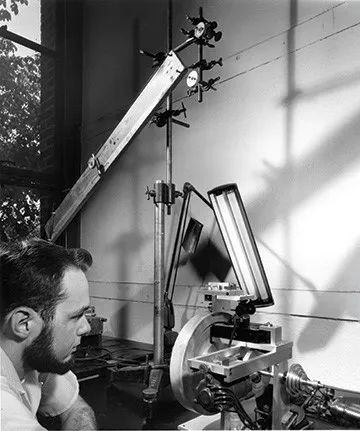

David Payne is in his lab

The solution to this problem comes from another branch of the laser family: fiber laser.

David Payne of the University of Southampton in the United Kingdom found that the erbium added to the fiber core can be emitted in the 1550 nm band, where silicon dioxide is the most transparent place. It is a good fiber amplifier under 980 nm pumping, which is a wavelength effectively generated by InGaAs diode laser.

Better yet, erbium has a wide range of gain bands, so it can amplify a series of wavelengths of about 1550 nm to achieve wavelength division multiplexing (WDM). Transferring optical fiber transmission to 1550 nm involves some complex engineering to obtain the correct details. The gain of the whole erbium band is uneven, so it needs precise optical devices to adjust the gain to achieve uniform power at all wavelengths. The dispersion needs to be compensated when transferring to 1550 nm, and the dispersion is zero at 1310 nm. However, dealing with these complex problems has increased the bandwidth of a single fiber by nearly 100 times, while other improvement measures have increased the bandwidth of the fiber by 4 times to 10 Gbit/s.

The timing seems perfect, because in the 1990s, Internet traffic is growing rapidly, and users and operators need more bandwidth. This growth made the telecom market booming in the 1990s. The shares of the previously unknown optical companies soared, and the market masters predicted a bright future. However, in the end, the great progress of optical technology has done what no one thinks is possible: providing too much bandwidth.

In many years after that, operators can buy dark step index single-mode fiber installed during the foam period at a few cents to provide more bandwidth. They get substantial benefits because most optical fibers can transmit many wavelength division multiplexing channels. At first, they used 10 Gbit/s per wavelength, but the introduction of coherent transmission and digital signal processing first increased the capacity to 100 Gbit/s per channel, and recently to 400 or 800 Gbit/s to cope with cloud computing and streaming media video. New large-mode area optical fibers are needed to transmit signals with the highest capacity, but they are basically improved versions of the old step-index single-mode optical fibers. Facts have proved that they are a great foundation for advanced transmission systems.

No. 8 Looking back on history, laser and optical fiber have become the cornerstone of technological society

In the past half century, a series of progress has been made in the field of laser and optical fiber.

Careful observation of the design of optical fiber systems in the past can see the continuous evolution of optical fiber, transmitter, receiver, transmission format and the system itself. New technologies have been added: coherent transmission and digital signal processing have replaced dispersion management to improve transmission capacity; In addition, they also extend the service life of the optical fiber that has been buried underground, which is a great advantage because the installation cost is usually higher than the cable itself.

Laser technology is also developing. In the early stage, most lasers turned less than a few percent of the input energy into output. Now, diodes and fiber lasers can convert more than half of the input energy into output beams. Optical pumping and nonlinear optical technology increase the variety of available wavelengths. The more we explore, the more we learn, and the more laser and optical fiber can do for us; These are breakthroughs that continue to advance.

Modern lasers and optical fibers are not the product of a single invention, but the cumulative creation of several generations of scientists and engineers. Contributors stand on the shoulders of giants; Other contributors now stand on the shoulders of giants in turn. This article can only list a few founders.

Some progress is earlier than the era discussed in this article. Snitzer invented the fiber laser in 1961, but this technology can only play its role when the diode laser is mature enough to provide the pump source; Bell Labs demonstrated coherent optical communication in hollow waveguides in the 1960s, but it only became practical with the emergence of digital signal processing around 2010; The material science used by Corning to purify fused quartz for cooking utensils is the basis of low loss optical fiber; The research of solid state physics has opened the door for semiconductor electronics, which has opened the door for composite semiconductors and diode lasers

Through the innovation of optics, lasers and optical fibers have laid the foundation for most of today’s optical work. In medicine, lasers and optical fibers can make sensitive measurements or perform life-saving operations. In industry, they can locate objects on the production line and weld thick metal plates. Lasers have discovered gravitational waves from the distant universe and created fascinating and powerful tools, such as frequency combs.

The breakthrough in laser and optical fiber has not only completely changed optics; They also make optics an important element of our technological society.

WhatsApp:

WhatsApp: Wechat

Wechat

Advantages of laser cutting nickel-titanium electrode 2024-05-06

In recent years, with the continuous development of medical technology, medical laser cutting machines play an important role in the manufacture of nickel-titanium electrode sheets. Next, we will introduce the application and advantages of our Men-luck laser cutting machine in t…

Laser cutting process of eye lens 2024-04-11

With the increasing demand for vision correction in modern society, glasses, as a common optical instrument for vision correction, play an indispensable role in People's Daily life. Lens processing is a delicate process that requires cutting and punching to complete the manufact…

Ultrafast femtosecond laser technology helps cardiovascular stent manufacturing 2024-04-08

With the soaring incidence of cardiovascular and cerebrovascular diseases, stent implantation has become one of the main methods of surgical treatment. Compared with traditional cutting equipment, medical laser cutting machine not only has good cutting quality, high cutting prec…

Application of laser cutting machine in mobile phone camera module manufacturing 2024-04-04

With the continuous progress of science and technology and the improvement of people's requirements for quality of life, the fields of smart wear, smart home, automotive electronics and mobile phone consumer electronics have been vigorously developed. In these fields, the camera…