Working principle of fiber laser cutting machine

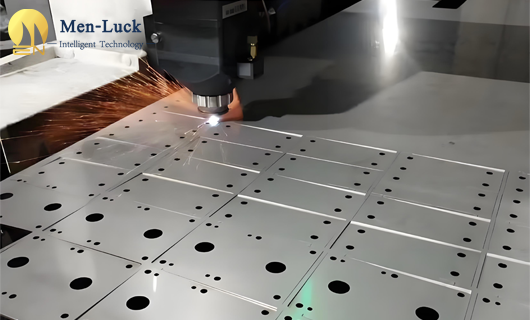

(Click 45 )The core technology of fiber laser cutting machine lies in its unique light source system. Unlike traditional CO2 lasers, fiber lasers use ytterbium-doped fiber as gain medium and generate high-energy laser through semiconductor pumping. This design not only improves the photoelectric conversion efficiency, but also significantly enhances the beam quality. The laser beam is precisely controlled by the collimator and focusing lens to form a high-energy density spot on the surface of the workpiece, instantly vaporizing or melting the material, and using auxiliary gas to blow the molten material away from the slit to achieve precise cutting.

The core components of the equipment include laser generator, cutting head, motion control system and auxiliary system. The laser generator generates a high-energy laser beam, the cutting head is responsible for the transmission and focusing of the beam, the motion control system ensures that the cutting head moves accurately along the predetermined trajectory, and the auxiliary system provides support functions such as gas and cooling. The coordinated work of these components ensures the efficient and stable operation of the equipment.

Compared with traditional cutting technology, fiber laser cutting has obvious advantages. Its cutting speed is 2-3 times that of traditional CO2 laser cutting, energy consumption is reduced by more than 30%, and it can achieve a more refined cutting effect. Especially in the field of thin plate processing, the advantages of fiber laser cutting machines are more prominent.

As a professional laser equipment manufacturer, MenLuck provides professional technical support and equipment quality for every customer, tracks the progress of equipment production and installation for each customer, and each device undergoes more than 3 days of equipment operation stability testing, and will conduct a final adjustment test before packaging and delivery to ensure that there are no problems with the equipment before delivery. Welcome to contact us if you have a need for laser equipment! E-Mail: info@menlaser.com WhatsApp: 86-18796969088

WhatsApp:

WhatsApp: Wechat

Wechat

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …

Core application of laser cutting machine in glass photoelectric encoder manufacturing 2025-06-03

As the core component of high-precision angle sensor, the processing quality of the transparent grid of glass photoelectric encoder directly affects the measurement accuracy and signal stability. Laser cutting technology breaks through the bottleneck of traditional processes wit…