What metals can laser welding machines weld

(Click 105 )With the continuous improvement of people’s requirements for technology, traditional welding can no longer meet customer needs. The emergence of the new generation of laser welding machines has promoted the development of welding technology and gradually expanded its application scope and industry.

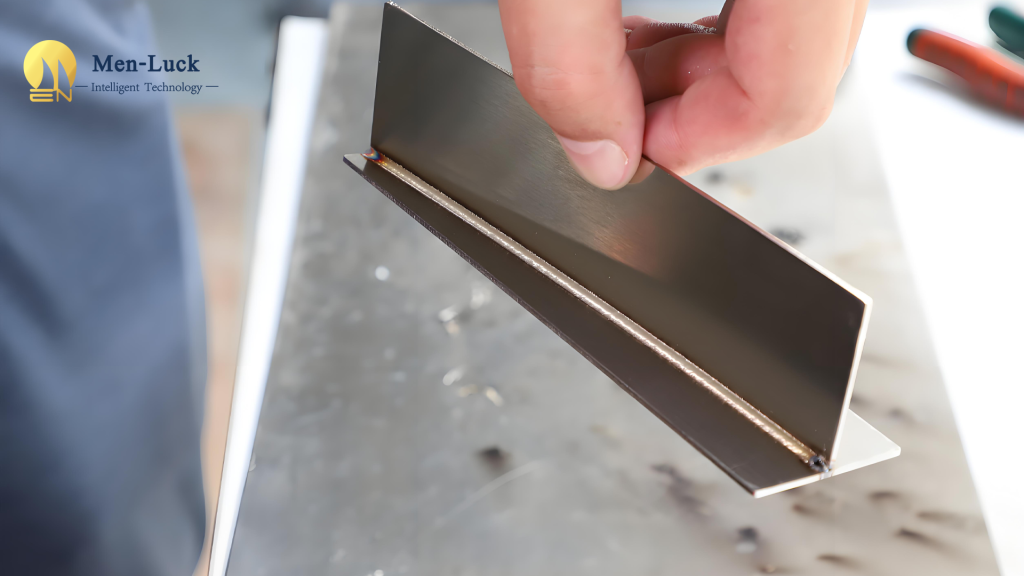

Laser welding is a heat treatment technique that uses a laser beam as a heat source. Compared with electron beams, plasma beams, and general mechanical processing, laser welding has many advantages. Due to the high laser beam focusing and high power density of the laser welding machine, effective welding of high melting point and high-strength alloy materials can be achieved.

In addition, laser welding machines can also be used for welding carbon steel, mold steel, alloy steel, stainless steel, titanium, and various metals and their alloys (such as nickel silver tin copper aluminum chromium niobium gold), as well as connecting the same materials (such as steel and Kovar alloy), and can meet the requirements of laser welding between different types of steel.

Compared to traditional methods, laser welding is more efficient and performs well in ensuring accuracy and speed; Easy to operate, safe, and easy to maintain; And it has excellent connection effect on welded metal materials. Laser welding machines can also achieve various methods such as point connection, diagonal connection, overlapping connection, and sealed connection, and are widely used in the fields of hardware processing, aerospace manufacturing, automotive manufacturing, and sheet metal processing.

Menluck specializes in manufacturing various laser equipment and provides various laser processing solutions for domestic and foreign enterprises. We support on-site factory inspections and sample sending services. We welcome all enterprises to contact our email for further information. E-mail: info@menlaser.com

WhatsApp:

WhatsApp: Wechat

Wechat

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …