What are the advantages of drug eluting stents?

(Click 838 )It can be said that until now, the field of coronary heart disease treatment is still the world of drug-eluting stents, and drug-eluting stents are the real king of this era.

The first generation of “drug coated stent”

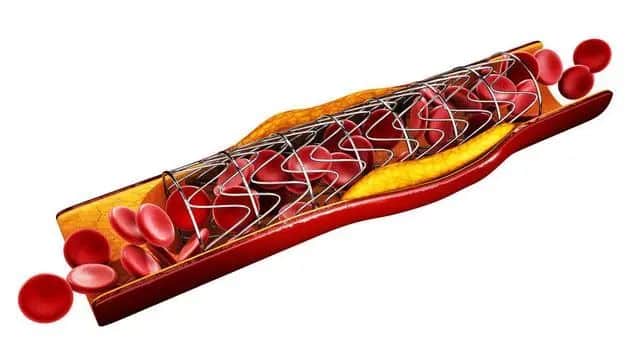

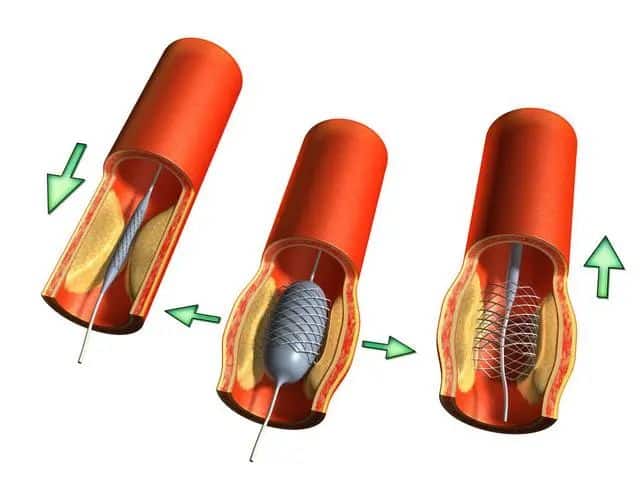

The first generation of drug-eluting stents are represented by sirolimus coated stents and paclitaxel coated stents, both of which are suitable for stainless steel frameworks as platforms. Drug coatings are non degradable polymers, mainly used to inhibit the occurrence of vascular endothelial hyperplasia.

At the beginning of the first generation of heart coated stents, people saw the huge advantages of drug coated stents, especially the reduction of stent restenosis. However, the good times are not long. After a period of observation, people found that drug-eluting stents still had many problems. For example, 12 months later, the rate of late and very late thrombosis events increased significantly. The main reason for these problems is that the drug coating on the stent surface may delay the endothelialization of the stent and cause local inflammatory reaction. Therefore, people are committed to improving the existing problems of the first generation of stents, and the second generation of drug-eluting stents gradually emerged.

The second generation of “drug coated stent”

In fact, Dr. Zhang personally caught up with the first generation of stents mentioned above. He also encountered many problems mentioned above at that time. It is well known that drug coated stents include scaffold framework, polymer coating and anti proliferation drugs. By the time of the second generation of drug-eluting stents, these three parts have been improved. Now, if patients with coronary heart disease undergo cardiac stent surgery, they basically use the improved second-generation “drug coated stent”, which has demonstrated excellent reliability and safety in clinical practice. This is a great progress compared with the previous first generation of drug coated stent.

The progress of human science and technology is endless. After the drug coated stent mentioned above, in fact, human may soon usher in a new era of stent, which is the era of biodegradable stent.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …