The slow development path of laser micromachining equipment for PCB circuit boards

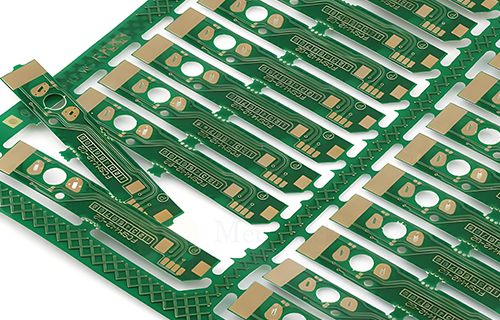

(Click 255 )PCB circuit board has become a global industry. Its output value accounts for 25% of the output value of electronic components. It accounts for a relatively large proportion in various electronic component industry segments, so it occupies an important position. The cutting process of PCB circuit boards is also constantly upgraded, which is important for The requirements for processing equipment are getting higher and higher, and traditional processing methods can no longer meet the demand. As an emerging environmentally friendly and efficient processing method, laser has become the best choice.

As major communication operators announce their entry into the 5G era, the development of the high-speed communication era has also accelerated the application fields of electronic components PCB and FPC. The corresponding laser technology is also a core force driving the development of the manufacturing industry. Men-luck has more than ten years of experience in laser production. Currently, laser micro-processing equipment mainly includes laser drilling machines, laser marking machines, laser welding machines, and laser cutting machines. It is a company integrating laser cutting, marking, and welding processes. A one-stop laser micromachining equipment service provider. There are complete types of equipment, rich models, and sufficient stock in stock.

Men-luck has been making its debut in the field of laser industrial equipment, and now it has updated and iterated its products step by step through accumulated practice. It has developed multiple series of precision laser cutting machines, marking machines, and welding machine equipment for the precision industry. It can reach 5um, and the cutting slit width is less than or equal to 20um. For example, laser microprocessing of PCB/FPC circuit boards and chips in the semiconductor industry, microprocessing of cardiac stents, vascular stents, and surgical instruments in the medical industry. Since its launch, PCB laser microprocessing equipment has been exported to more than a dozen countries and regions abroad. It operates well, has satisfactory after-sales service, and has been unanimously recognized by customers.

In the days when men-luck was reforming and innovating laser processing equipment, it repeatedly tested new samples, invested in high-precision testing equipment, continuously explored and debugged product accuracy and technology, and innovated processes and solutions. Through trial machine mass production, we provide customers with more stable and efficient equipment models. As a country with the industrial application of lasers, we keep up with the development of the times, continuously improve our independent innovation capabilities, and use the spirit of craftsmanship to endow equipment with quality and ensure the quality and performance of the equipment. New and old customers from all over the world are welcome to contact us to make an appointment for proofing services!

WhatsApp:

WhatsApp:

Wechat

Wechat

Factors affecting the processing quality of laser cutting machine 2024-03-25

Laser cutting is a more common processing method in laser processing, and it is also a relatively simple one. The processing quality of the laser cutting machine is mainly reflected in the processing accuracy and surface quality, and the cutting surface quality is determined by …

Application of laser drilling machine in photovoltaic industry 2024-03-18

Laser drilling uses a high-energy-density laser beam to locally heat the material to a high enough temperature to evaporate, melt or vaporize it to form holes. The key to laser drilling lies in precise control of energy density, line speed and focus position to achieve precise p…

cutting machine manufacturers explain in detail the differences between ultraviolet, red light and green light sources? 2024-03-14

The most commonly used light sources for laser cutting machines are mainly red light, ultraviolet light, and green light. Each type of light source has different advantages. According to the characteristics, thickness and processing quality requirements of the processing materia…

Application and processing advantages of laser cutting machine in metal speaker mesh 2024-03-11

Metal speaker mesh is mainly used in sound-producing components of electronic equipment such as automobiles, mobile phones, and stereos. It is made of metal and has the characteristics of durability, good air permeability, etc. In the process of forming the metal speaker mesh, a…