Precision medical laser cutting machine: technological innovation in bone reamer manufacturing

(Click 76 )The application of precision medical laser cutting machine in the field of bone reamer manufacturing has ushered in a new era of medical device processing. This high-precision processing equipment uses advanced laser technology to achieve micron-level processing accuracy, which has brought a revolutionary breakthrough in the manufacturing of bone reamer.

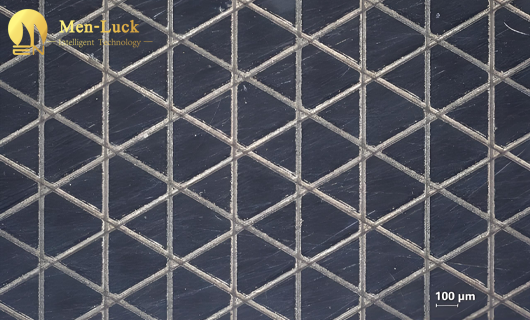

In terms of processing accuracy, precision medical laser cutting machines have demonstrated excellent performance. The high-precision cutting level ensures the sharpness and consistency of the bone reamer blade, making the cutting force more uniform during surgery and reducing tissue damage. Taking a 2mm diameter bone reamer as an example, the dimensional tolerance of laser cutting can be controlled within ±0.005mm, far exceeding traditional processing methods.

Improved processing efficiency is another major advantage of precision medical laser cutting machines. Traditional bone reamer manufacturing requires multiple processes such as grinding and polishing, while laser cutting can achieve one-time molding, shortening the processing time by more than 60%. Taking titanium alloy bone reamer as an example, the laser cutting speed can reach 300mm per minute, and saves subsequent processing steps, significantly improving production efficiency.

In terms of material processing, precision medical laser cutting machines have unique advantages. Medical-grade titanium alloys, stainless steel and other difficult-to-process materials can achieve ideal processing quality through laser cutting. Especially for the processing of titanium alloys, laser cutting avoids the problem of heat-affected zone in traditional processing and ensures the biocompatibility of materials.

The application of precision medical laser cutting machines has not only improved the manufacturing level of bone reamer drills, but also promoted the technological progress of the entire medical device industry. As a professional laser cutting machine manufacturer, MenLuck mainly deals in various laser cutting machines, laser marking machines, and laser welding machines, which are widely used in 3C, medical, hardware, home appliances, etc. Companies interested in laser equipment are welcome to contact us. E-mail: info@menlaser.com

WhatsApp:

WhatsApp: Wechat

Wechat

Femtosecond laser cutting machine reshapes the limit of ultra-precision manufacturing 2025-07-08

In the field of cutting-edge manufacturing that pursues micron or even nanometer precision, traditional processing methods have gradually reached physical limits. The emergence of femtosecond laser cutting machines, with its revolutionary "cold processing" characteristics brough…

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…