Planar instrument laser cutting machine helps medical precision manufacturing

(Click 82 )In the medical field, the precision processing of planar instruments (such as surgical blades, orthopedic bone plates, dental repair plates, etc.) is directly related to clinical safety and treatment effects. Traditional stamping, etching and other processes are difficult to meet the manufacturing requirements of micron-level precision and complex structures. The planar instrument laser cutting machine has become the core technical equipment for the production of high-end medical consumables with its non-contact, high flexibility, and zero pollution characteristics, pushing the industry towards “zero defect manufacturing”.

Micron-level precision, eliminating clinical risks

Ultra-thin material cutting: machining the edge of the surgical blade on a 0.1mm thick stainless steel sheet, the incision roughness Ra <0.4μm, no burr residue, avoiding intraoperative tissue tearing;

Complex hollow structure: The screw hole and the weight reduction groove of the orthopedic locking bone plate are cut synchronously, with a hole diameter tolerance of ±5μm to ensure the precise matching of the bone plate and the screw;

Medical-grade cleanliness: non-contact processing avoids metal debris contamination and meets the biocompatibility requirements of the implant surface.

Multi-material compatibility, unlocking innovative designs

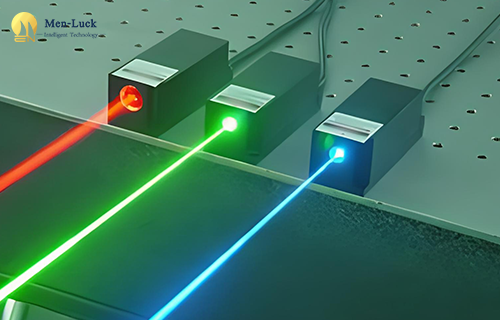

High-reflective metal: Green laser (532nm) cuts pure titanium or titanium alloy dental restorations, reducing reflection loss by 80% and increasing processing efficiency by 3 times;

Memory alloy: Picosecond laser cold processing of nickel-titanium alloy vascular clips, heat-affected zone <10μm, perfectly retaining shape memory effect;

Composite material: UV laser (355nm) processes polyetheretherketone (PEEK) and metal composite bone plates to avoid delamination or carbonization.

Intelligent production, cost reduction and efficiency improvement

Batch nesting optimization: Intelligent typesetting software increases the utilization rate of titanium plates from 65% to 90%, and a single plate can cut 30% more parts;

Full process traceability: Laser marking and implanting a unique QR code to achieve full life cycle tracking from raw materials to the patient end.

WhatsApp:

WhatsApp: Wechat

Wechat

Femtosecond laser cutting machine reshapes the limit of ultra-precision manufacturing 2025-07-08

In the field of cutting-edge manufacturing that pursues micron or even nanometer precision, traditional processing methods have gradually reached physical limits. The emergence of femtosecond laser cutting machines, with its revolutionary "cold processing" characteristics brough…

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…