Laser precision cutting of cardiovascular stents has unique advantages

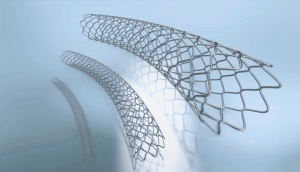

(Click 1,047 )Cardiovascular stents are fine-grained structures. After balloon angioplasty to treat blocked veins or arteries, cardiovascular stents are placed in human blood vessels. Therefore, it is a prerequisite to ensure that the support is green and pollution-free, and also to ensure the strength of the support, and to ensure that the surface of the support is smooth and burr free. These are beyond the reach of traditional processing equipment.

Advantages of laser cutting machine:

Precision laser cutting machines, which are now mainly used in the medical device industry, have always been the driving force for the development of high-quality and high reliability industrial lasers and motion control systems. Laser cutting machine is also used in the processing of cardiovascular stents. Because the laser cutting machine has high precision and high speed; The whole processing process is automatically controlled by computer software, with real-time feedback on the software interface, timely understanding of the processing status, non-contact processing scheme, no mechanical stress and deformation, simple operation and high cutting precision.

The bracket is formed by cutting thin-walled pipes with a laser cutting machine. Therefore, although some excess metal is removed by laser, it can still bear external forces. In order to reduce the influence of residual thermal effect and cut complex design patterns with burr free edges, a laser device is usually selected, and the fiber laser cutting machine is the most used.

With the rapid development of laser processing, laser welding machines and laser marking machines have played a unique role in the field of life. Laser cutting machine is also indomitable. It plays a unique role not only in medical equipment, but also in cloth cutting!

WhatsApp:

WhatsApp: Wechat

Wechat

Factors affecting the processing quality of laser cutting machine 2024-03-25

Laser cutting is a more common processing method in laser processing, and it is also a relatively simple one. The processing quality of the laser cutting machine is mainly reflected in the processing accuracy and surface quality, and the cutting surface quality is determined by …

Application of laser drilling machine in photovoltaic industry 2024-03-18

Laser drilling uses a high-energy-density laser beam to locally heat the material to a high enough temperature to evaporate, melt or vaporize it to form holes. The key to laser drilling lies in precise control of energy density, line speed and focus position to achieve precise p…

cutting machine manufacturers explain in detail the differences between ultraviolet, red light and green light sources? 2024-03-14

The most commonly used light sources for laser cutting machines are mainly red light, ultraviolet light, and green light. Each type of light source has different advantages. According to the characteristics, thickness and processing quality requirements of the processing materia…

Application and processing advantages of laser cutting machine in metal speaker mesh 2024-03-11

Metal speaker mesh is mainly used in sound-producing components of electronic equipment such as automobiles, mobile phones, and stereos. It is made of metal and has the characteristics of durability, good air permeability, etc. In the process of forming the metal speaker mesh, a…