How to process Laptop —— laser cutting technology of structural parts

(Click 957 )

Laptop is indispensable in our daily work and study, but how is it processed?Many of its structural parts are actually completed by laser processing.

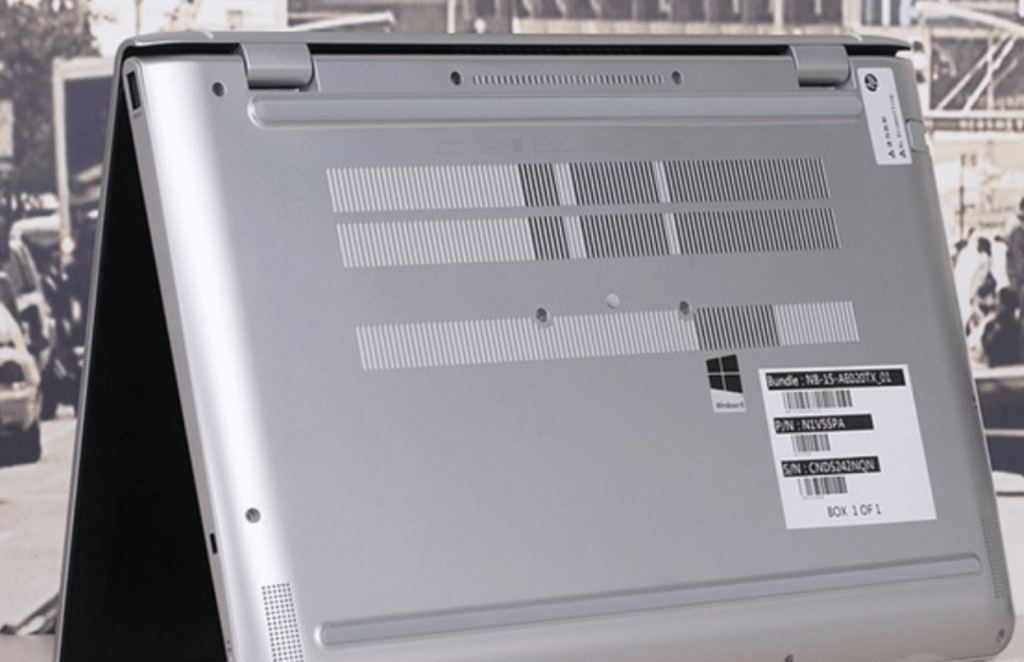

Laptop – rear cover cooling hole

Such as: heat dissipation holes, speaker holes, and other types of micropores and coupling shafts, keyboards, and so on.

Precision 3C metal structure laser cutting machine

Our company’s “precision 3C metal structure laser cutting machine yc-eplc6045” can be competent for laser processing of various structural parts in notebook computers.

It can process a variety of materials such as steel, aluminum, copper, magnesium aluminum alloy, titanium, ceramics, sapphire, etc. it supports laser cutting, drilling, slotting and other processing processes of planar & curved surface instruments.

Compared with other processes, laser processing technology has its unique advantages, such as high efficiency, high precision, less post-processing procedures and low cost. Error ≤± 10 μ m. If the automatic feeding and unloading system is selected, the labor cost can be greatly saved and the production efficiency can be improved! Help customers reduce costs and increase efficiency!

The laser cutting machine adopts the self-developed direct drive mobile double drive motion platform. Both the left and right Y axes are actively driven. Through the high-end controller, the real-time feedback correction is realized to ensure that the double drive motion platform of the gantry structure is synchronous, and the processing accuracy can be taken into account while ensuring the processing efficiency!

In addition, it also provides optional functions such as dual station and visual positioning.

WhatsApp:

WhatsApp: Wechat

Wechat

Factors affecting the processing quality of laser cutting machine 2024-03-25

Laser cutting is a more common processing method in laser processing, and it is also a relatively simple one. The processing quality of the laser cutting machine is mainly reflected in the processing accuracy and surface quality, and the cutting surface quality is determined by …

Application of laser drilling machine in photovoltaic industry 2024-03-18

Laser drilling uses a high-energy-density laser beam to locally heat the material to a high enough temperature to evaporate, melt or vaporize it to form holes. The key to laser drilling lies in precise control of energy density, line speed and focus position to achieve precise p…

cutting machine manufacturers explain in detail the differences between ultraviolet, red light and green light sources? 2024-03-14

The most commonly used light sources for laser cutting machines are mainly red light, ultraviolet light, and green light. Each type of light source has different advantages. According to the characteristics, thickness and processing quality requirements of the processing materia…

Application and processing advantages of laser cutting machine in metal speaker mesh 2024-03-11

Metal speaker mesh is mainly used in sound-producing components of electronic equipment such as automobiles, mobile phones, and stereos. It is made of metal and has the characteristics of durability, good air permeability, etc. In the process of forming the metal speaker mesh, a…