Glass slide quartz glass sheet laser cutting process

(Click 77 )Glass slides are glass sheets used to carry samples in experiments and are widely used in medical, scientific research, and teaching. In the process of making glass slides, the glass needs to be cut first. The laser cutting machine can quickly and accurately cut the required size of glass slides from the raw material glass plate. Compared with traditional methods, laser cutting machines have higher processing speeds and better processing quality.

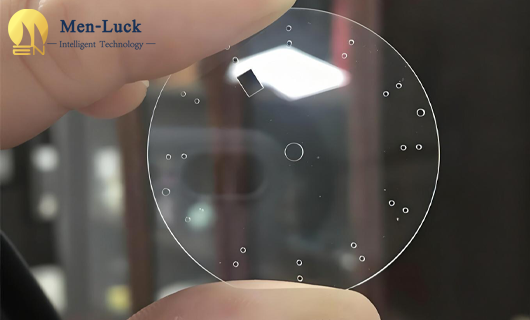

The glass slide laser cutting machine is a professional glass laser cutting equipment. This machine uses a laser beam to cut glass in a non-contact manner. The principle is to concentrate energy on a specific area of the workpiece and heat the area to a preset temperature. After rapid heating, rapid cooling is immediately carried out to cause vertical stress in the glass, forming a crack without debris or cracks. Since the crack is caused by heat rather than mechanical action, no debris or micro cracks will be generated. This makes the strength of the laser-cut edge better than traditional scratching and splitting methods, while reducing the need for fine processing and even completely avoiding the generation of glass fragments. This is a fast and efficient glass slide cutting device.

As a kind of precision laser cutting machine, the slide laser cutting machine can play a huge role in many fields such as biomedicine and material science, and promote more breakthroughs and progress in related industries. Men-luck is a professional laser cutting machine manufacturer. Its main products include laser welding machines, laser cutting machines, and laser marking machines, which are widely used in various industries. Enterprises with needs for laser processing are welcome to contact us.

WhatsApp:

WhatsApp: Wechat

Wechat

Femtosecond laser cutting machine reshapes the limit of ultra-precision manufacturing 2025-07-08

In the field of cutting-edge manufacturing that pursues micron or even nanometer precision, traditional processing methods have gradually reached physical limits. The emergence of femtosecond laser cutting machines, with its revolutionary "cold processing" characteristics brough…

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…