Fiber laser cutting machine: a revolutionary tool for sheet metal processing

(Click 38 )The application of fiber laser cutting machine in the field of sheet metal processing marks an important step for modern manufacturing industry towards high precision and high efficiency. This advanced processing equipment uses high energy density laser beam for cutting, achieving precision and speed that are difficult to achieve with traditional processing methods, and completely changing the industry pattern of sheet metal processing.

In terms of processing accuracy, fiber laser cutting machine shows incomparable advantages. Its laser beam diameter can be controlled within 0.1mm, and the minimum incision width can reach 0.01mm, achieving micron-level processing accuracy. This level of accuracy not only meets the needs of high-end manufacturing fields such as precision electronic components and medical devices, but also greatly reduces subsequent processing procedures and improves product yield.

High processing efficiency is another significant feature of fiber laser cutting machine. Traditional sheet metal processing requires multiple processes, while laser cutting can achieve one-time forming, and the processing speed can reach tens of meters per minute. Taking 2mm thick stainless steel plate as an example, the laser cutting speed can reach more than 15 meters per minute, which is 5-10 times that of traditional processing methods. The improvement in efficiency directly reduces production costs and shortens product delivery cycles.

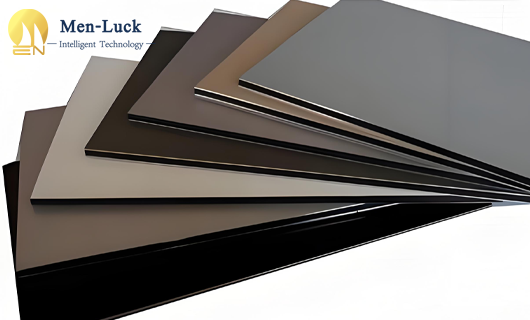

In terms of material adaptability, fiber laser cutting machines show strong versatility. Whether it is ordinary carbon steel, stainless steel, or difficult-to-process materials such as aluminum alloy and copper alloy, high-quality cutting can be achieved. In particular, the processing ability of highly reflective materials solves the difficulties in traditional processing. Taking copper as an example, the fiber laser cutting machine successfully overcomes the high reflectivity of the material to the laser through special wavelength and pulse control.

MenLuck specializes in the research and development, production, marketing and service of laser equipment such as metal laser cutting machines, brittle material laser cutting machines, and precision medical equipment laser cutting machines. They are widely used in 3C, medical, hardware, home appliances, etc. Companies interested in laser cutting machines are welcome to contact us. E-mail: info@menlaser.com WhatsApp: 86-18796969088

WhatsApp:

WhatsApp: Wechat

Wechat

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …

Core application of laser cutting machine in glass photoelectric encoder manufacturing 2025-06-03

As the core component of high-precision angle sensor, the processing quality of the transparent grid of glass photoelectric encoder directly affects the measurement accuracy and signal stability. Laser cutting technology breaks through the bottleneck of traditional processes wit…