Factors affecting cutting of laser tube cutting machine

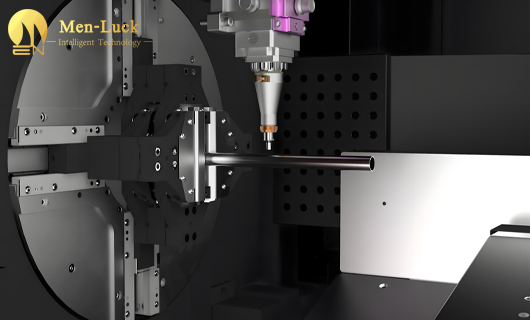

(Click 67 )The size of laser power will have an important impact on laser cutting. Theoretically, the greater the laser power of the laser tube cutting equipment, the greater the cutting speed that can be obtained, but combined with the characteristics of the tube itself, the maximum cutting power is not the best choice. When the cutting power is increased, the mode of the laser itself also changes, which will affect the focus of the laser beam. In actual processing, we often choose to let the focus obtain the highest power density when it is less than the maximum power, so as to ensure the efficiency and cutting quality of the entire laser cutting.

When laser cutting tubes, the cutting speed must be within a certain range to obtain better cutting quality. If the cutting speed is slow, too much heat will accumulate on the surface of the tube, the heat-affected zone will become larger, the slit will become wider, and the discharged hot melt material will burn the incision surface, making the incision surface rough. When the cutting speed is increased, the average slit width of the tube circumference becomes smaller, and the smaller the diameter of the cut tube, the more obvious this effect is. As the cutting speed increases, the laser action time shortens, the total energy absorbed by the tube decreases, the temperature at the front end of the tube decreases, and the slit width decreases. If the cutting speed is too fast, the tube may not be cut through or cut continuously, thus affecting the overall cutting quality.

When laser cutting tubes, the characteristics of the tube itself will also have a great impact on the processing process. For example, the size of the round tube diameter has a significant impact on the processing quality. Through the study of laser cutting of thin-walled seamless steel tubes, it was found that when the laser cutting tube equipment keeps all process parameters unchanged, the slit width will continue to increase as the tube diameter continues to increase.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …