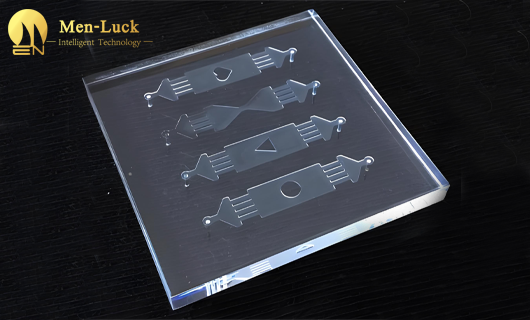

Application of precision medical laser cutting machine in microfluidic chip manufacturing

(Click 42 )As a key tool for modern biomedical research, microfluidic chips have complex microchannels and functionalized structures that place extremely high demands on manufacturing processes. With its unique advantages, precision medical laser cutting technology breaks through the bottleneck of traditional processing, injects new vitality into cutting-edge fields such as organ chips and instant diagnostic equipment, and promotes life science research and precision medicine to a higher dimension.

Laser cutting technology can flexibly cope with a variety of materials such as PDMS, glass, and hydrogels, and achieve precise molding of micron-level flow channels and chambers in integrated processing. Whether it is a simulated vascular network on a flexible polymer substrate or a multi-stage filtration structure in a hard glass chip, non-contact processing can be used to avoid material deformation or contamination. Compared with traditional photolithography, laser technology is particularly good at the direct construction of complex three-dimensional structures, providing key technical support for organ chips to simulate real physiological environments.

The deep integration of laser processing equipment and automated production lines can achieve high-throughput manufacturing on wafer-level materials. Through the intelligent path optimization system, the processing speed is greatly improved, and the yield rate is stable at more than 99%. This breakthrough significantly reduces the cost of microfluidic chips and accelerates the commercialization of portable diagnostic devices.

Laser technology can not only process physical structures, but also achieve functional integration. Through surface modification technology, hydrophilic and hydrophobic patterns are directly generated in microchannels to achieve intelligent manipulation of droplets; combined with laser direct writing technology, micro sensors can be embedded inside the chip to monitor biochemical parameters such as temperature and pH in real time. This “structure-function” integrated manufacturing model provides a new paradigm for the development of smart biochips.

From basic research to clinical transformation, precision laser cutting technology is becoming the core driving force for innovation in microfluidic chips. It not only solves the accuracy and efficiency problems of traditional manufacturing, but also expands the application boundaries of biochips through multifunctional integration, bringing revolutionary breakthroughs in disease modeling, personalized medicine and other fields. This technology will continue to drive medical equipment to evolve in a smarter and more precise direction.

WhatsApp:

WhatsApp: Wechat

Wechat

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …

Core application of laser cutting machine in glass photoelectric encoder manufacturing 2025-06-03

As the core component of high-precision angle sensor, the processing quality of the transparent grid of glass photoelectric encoder directly affects the measurement accuracy and signal stability. Laser cutting technology breaks through the bottleneck of traditional processes wit…