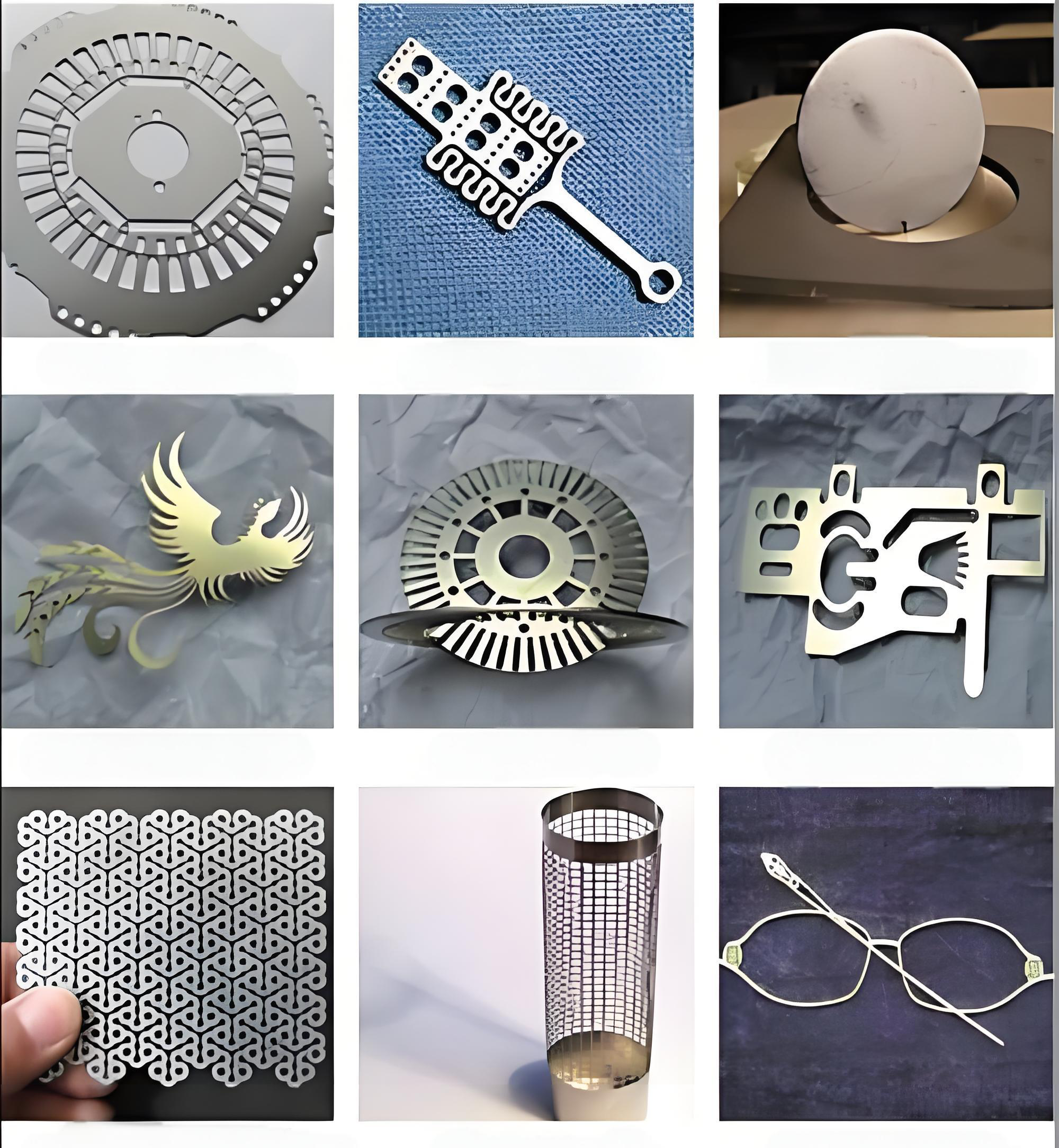

Application of laser cutting machines in different fields of precision structural parts

(Click 9 )Electronic information field

In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit boards (PCBs), connectors, sensors and other structural parts.

In PCB processing, laser cutting can achieve high-precision micro-hole processing and line cutting, and can cut lines with a width of only tens of microns, effectively improving the integration and performance of circuit boards. At the same time, for the cutting of flexible circuit boards (FPCs), laser cutting machines can avoid edge burrs, deformation and other problems caused by traditional mechanical cutting, and ensure the quality and reliability of circuit boards. In the processing of connectors and sensor structural parts, laser cutting can accurately process complex shapes and tiny holes to meet the development trend of miniaturization and precision of electronic components.

Aerospace field

The aerospace field has extremely stringent requirements on the quality and performance of precision structural parts. Laser cutting machines are widely used in the processing of aircraft engine blades, aircraft skins, satellite parts, etc. The shape of aircraft engine blades is complex, and high requirements are required for high temperature resistance and corrosion resistance. Laser cutting machines can cut complex cooling channels while ensuring blade accuracy, thereby improving the heat dissipation performance and service life of blades.

For aircraft skins, laser cutting can achieve stress-free cutting, avoid stress concentration problems caused by traditional cutting methods, and improve the strength and reliability of the skins. In satellite parts processing, laser cutting can process high-precision mirror brackets and other structural parts to ensure the optical performance and working stability of satellites.

Medical device field

The precision structural parts in medical devices are directly related to the life, health and treatment effects of patients, and have extremely high requirements for processing accuracy and biocompatibility. Laser cutting machines have unique advantages in the processing of structural parts such as surgical instruments and implantable medical devices.

In the processing of surgical instruments, such as precision surgical blades and vascular stents, laser cutting can process extremely sharp blades and complex mesh structures to improve the operating performance and treatment effects of surgical instruments. For implantable medical devices, such as artificial joints and pacemaker housings, laser cutting can not only ensure the high precision and complex shapes of structural parts, but also optimize the surface quality of materials by controlling cutting parameters, improve their biocompatibility, and reduce human body rejection reactions.

WhatsApp:

WhatsApp: Wechat

Wechat

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…